Blog

How to Use a 3 Pump System for Optimal Performance?

In the world of fluid management, a 3 pump system can significantly enhance operational efficiency. Renowned expert John Smith, a leader in pump technology, notes, “A well-structured 3 pump setup can outperform traditional methods.” The concept revolves around the seamless integration of multiple pumps, optimizing performance while ensuring reliability.

Implementing a 3 pump system requires careful planning. Each pump plays a specialized role that contributes to the overall efficiency. For instance, one may focus on delivery, while another handles recycling. However, organizing these pumps is not without its challenges. Balancing the workload can lead to unexpected complications.

Proper maintenance is essential for a 3 pump system. Neglect can result in reduced performance or even pump failure. A consistent monitoring routine is vital. The potential for oversights exists, and it is crucial to reflect on system performance regularly. This reflection can identify improvements, ensuring that the 3 pump system operates at its best.

Understanding the Basics of a 3 Pump System Design

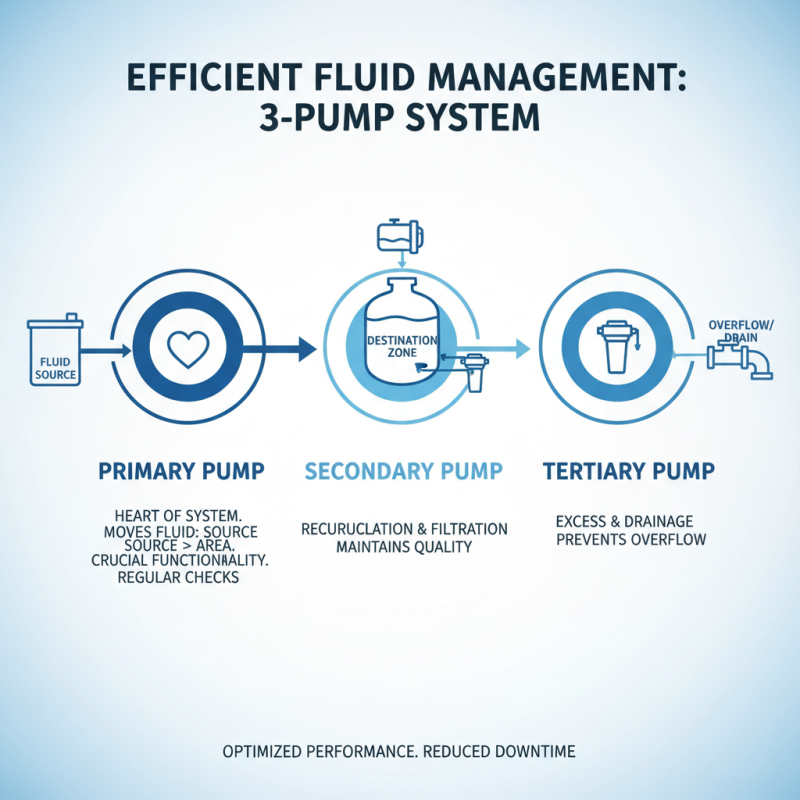

A 3 pump system is designed to enhance efficiency in fluid management. It typically consists of three distinct pumps that work collaboratively. Each pump can be dedicated to specific tasks like transfer, circulation, or pressure increase. This design helps in reducing wear on each unit, which can lead to a longer lifespan.

Understanding the basics of this setup is crucial. The first pump may handle initial fluid intake, while the second circulates it. The third ensures pressure stability throughout the system. Misalignment in pump functions can lead to inefficiencies. If one pump fails, it can disrupt the entire operation. Monitoring performance frequently can help address issues early.

Floors and walls in pump rooms need careful planning. Adequate space for maintenance is vital. Neglecting these details may cause downtime during repairs. Sometimes, operators overlook minor adjustments that significantly improve performance. Regularly revisiting the design principles can yield beneficial insights.

Key Components of a 3 Pump System and Their Functions

A 3 pump system is essential for efficient fluid management. Each pump has a unique role. The primary pump is the heart of the system. It moves fluid from the source to the designated area. It is crucial to maintain its functionality. Regular checks can prevent issues that may arise unexpectedly.

The secondary pump is often used for redundancy. If the primary pump fails, the secondary one takes over. This backup system reduces downtime. Sometimes, people overlook its importance until it is too late. Testing it regularly is necessary to catch potential problems before they escalate.

The third pump usually serves specialized functions. It can handle different fluid types or pressures. Its role may vary depending on system design. Sometimes, operators forget to configure it correctly. Regular training and updates can improve understanding of all pumps’ functions. Ensuring all parts work well together is vital for optimal performance.

Step-by-Step Installation Process for a 3 Pump System

Installing a 3 pump system can greatly improve efficiency. Start by gathering your materials. You will need the pumps, pipes, and connectors. Ensure all components are compatible. Proper planning will prevent issues later.

Begin installation by selecting an appropriate location. It should be well-ventilated and accessible. Carefully layout the pump placement. Take measurements to ensure accuracy. Sketch a diagram to visualize the setup. It’s easy to overlook a misaligned pipe.

When connecting the pumps, check each connection closely. Tighten fittings without overdoing it. Leaks can create problems. It may take a few tries to get everything aligned correctly.

Tips: Always double-check your work. A small mistake can lead to big problems. Take your time with the installation. Rushing often results in needing to redo parts of the job.

Once installed, run the system and watch for any irregularities. Adjust the settings as necessary. If an issue arises, revisit each connection. It’s better to fix the problems early.

Optimal Performance of a 3 Pump System

Optimal Operating Conditions for 3 Pump System Efficiency

Optimal operating conditions are crucial for maximizing the efficiency of a 3 pump system. Proper alignment and spacing of the pumps can greatly impact performance. Research indicates that reducing friction losses can enhance system efficiency by up to 15%. Optimizing the operating speed of each pump is also essential. Running pumps at their best efficiency point (BEP) reduces energy consumption.

Tips: Regularly inspect the pumps for wear and misalignment. Small adjustments can lead to significant performance gains.

Water quality affects pump operation too. Contaminants can cause wear and reduce efficiency. Ensuring the fluid is clean extends the lifespan of the equipment and maintains peak performance. A recent industry report noted that clean fluid systems reduce maintenance costs by 25%.

Tips: Implement a robust filtration system to address water quality. Monitor fluid parameters regularly to detect potential issues.

Operating pressure affects system stability. Maintaining a consistent pressure is vital. Pressure fluctuations can lead to inefficiencies and damage. A study revealed that maintaining optimal pressure can improve energy efficiency by 20%. However, achieving this requires attention to detail and ongoing monitoring.

Tips: Use pressure gauges to track performance closely. Anomalies should be addressed promptly to prevent future complications.

Common Maintenance Practices for Longevity of 3 Pump Systems

Maintaining a 3 pump system is crucial for its longevity and performance. Regular inspection of each pump is a must. Look for leaks or unusual noises. Small issues can escalate quickly. Check the fluid levels and ensure they are within the recommended range. Inadequate fluid can lead to overheating and damage.

Filters should be cleaned often. Clogged filters can reduce efficiency. Replace them as needed. A clean system runs more smoothly. Additionally, scheduling routine maintenance can prevent unexpected breakdowns. Technicians can spot problems you might miss.

Finally, keep a maintenance log. Note any irregularities and repairs made. This helps track performance over time. Reflecting on past issues can provide insights for future improvements. Don’t neglect the little things. They make a big difference in the long run.

How to Use a 3 Pump System for Optimal Performance? - Common Maintenance Practices for Longevity of 3 Pump Systems

| Maintenance Practice | Frequency | Purpose | Expected Outcome |

|---|---|---|---|

| Inspect Pump Seals | Monthly | Prevent leaks | Enhanced efficiency |

| Check Motor Alignment | Quarterly | Avoid vibrations | Reduced wear |

| Lubricate Bearings | Every 6 months | Minimize friction | Extended lifespan |

| Examine Pump Strainers | Monthly | Maintain flow rate | Consistent operations |

| Calibrate Flow Sensors | Annually | Ensure accuracy | Optimized performance |

Related Posts

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency

-

2025 Top 10 Chemical Metering Pumps for Precision Fluid Control

-

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety

-

2025 Top Chemical Metering Pump Innovations and Best Practices

-

How to Choose the Right Diaphragm Chemical Metering Pump for Your Needs

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics