Blog

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety

In the modern industrial landscape, the significance of chemical metering cannot be overstated, as it plays a crucial role in optimizing efficiency and ensuring safety across various sectors. According to a report by MarketsandMarkets, the global chemical metering pumps market is projected to grow from $3.5 billion in 2020 to $4.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5%. This growth underscores the increasing reliance on precise chemical dosing systems to enhance operational efficiency and minimize risks associated with chemical handling. Accurate chemical metering allows industries to maintain strict compliance with safety regulations while reducing waste and improving resource management.

As industries strive for sustainability and cost-effectiveness, adopting advanced chemical metering technologies has become imperative to not only bolster productivity but also protect personnel and the environment from hazardous substances.

How to Select the Right Chemical Metering System for Your Industry Needs

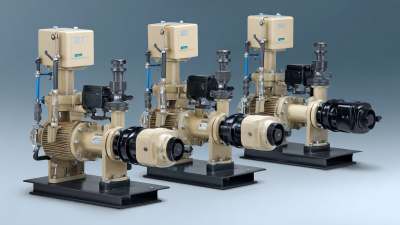

Selecting the right chemical metering system is crucial for enhancing efficiency and ensuring safety in various industries. According to a report by MarketsandMarkets, the global market for chemical metering pumps is expected to grow from USD 3.78 billion in 2021 to USD 5.09 billion by 2026, representing a compound annual growth rate (CAGR) of 6.3%. This growth underscores the increasing recognition of precision in chemical dosing processes. Industries such as water and wastewater treatment, pharmaceuticals, and food processing demand metering systems that deliver accurate measurements to prevent costly errors and maintain compliance with safety regulations.

When selecting a chemical metering system, it is essential to assess the specific demands of your industry. Key factors to consider include the type of chemicals being handled, the required flow rates, and the integration capabilities with existing systems. A study by ResearchAndMarkets highlights that improper chemical dosing can lead to not only regulatory fines but also environmental hazards, emphasizing the importance of choosing reliable equipment.

Systems featuring advanced calibration technologies and real-time monitoring capabilities can significantly enhance operational efficiency by minimizing waste and ensuring consistent application of chemicals, thus safeguarding both production quality and workplace safety.

How to Ensure Accurate Chemical Measurements to Optimize Processes

Accurate chemical metering is crucial for optimizing industrial processes, significantly impacting both efficiency and safety. According to a report by the International Society for Automation (ISA), approximately 30% of production inefficiencies are attributed to improper chemical dosing. Ensuring precise measurements can help mitigate waste and prevent costly errors, which, in turn, drives overall productivity. Industries that adopt advanced chemical metering technologies, such as flowmeters and automated dosing systems, have recorded a 20% increase in operational efficiency, as evidenced in studies by the Chemical Processing Association.

To ensure accurate chemical measurements, companies should implement regular calibration and maintenance of their metering systems. The United States Environmental Protection Agency (EPA) highlights that regular checks can reduce inaccuracies by as much as 15%, enhancing compliance with safety regulations. Furthermore, investing in real-time monitoring systems allows for instant feedback and adjustments, minimizing the risk of over- or under-dosing, which can have severe repercussions. As industries increasingly harness data analytics and smart technologies, the potential for improved chemical management grows, leading to safer and more efficient operations.

How to Implement Safety Protocols in Chemical Metering Operations

In chemical metering operations, implementing safety protocols is crucial to ensure both efficient and safe processes. First, operators should establish comprehensive training programs that emphasize the importance of proper handling techniques and the potential hazards of chemicals. Regular drills and refresher courses can keep safety at the forefront of employees’ minds, allowing them to respond effectively to any unexpected situations. Furthermore, creating clear operational procedures helps to standardize how chemicals are measured, mixed, and stored, minimizing the risk of accidents.

Equally important is the use of appropriate equipment designed with safety features. Automated metering systems can reduce human error by allowing precise control over chemical flow rates. Additionally, implementing regular maintenance schedules ensures that all equipment operates correctly, preventing leaks or malfunctions that could pose safety risks. Real-time monitoring tools can also provide immediate feedback on metering operations, allowing operators to make adjustments promptly. By prioritizing these safety protocols, industries can enhance both operational efficiency and the well-being of their workforce while maintaining compliance with regulatory standards.

How to Maintain and Troubleshoot Your Chemical Metering Equipment

Proper maintenance and troubleshooting

of chemical metering equipment are crucial for ensuring operational efficiency and safety in industries that rely on precise chemical dosing. Regular inspections and maintenance can help identify potential issues before they escalate. According to a report by the American Chemical Society, equipment failures can decrease productivity by up to 20%, emphasizing the need for proactive measures. Implementing a routine maintenance schedule not only maximizes uptime but also extends the lifespan of the equipment, which can result in significant cost savings.

When troubleshooting chemical metering systems, it's essential to analyze common issues such as inaccurate flow rates, leaks, or component failures. A study from the Process Industry Practices indicates that improper calibration can lead to flaws in chemical consumption, potentially risking safety and compliance with environmental regulations. Employing advanced monitoring technologies can assist operators in diagnosing issues in real time, allowing for immediate correction and minimizing disruptions. By understanding and addressing these challenges, industries can enhance their overall performance and maintain a safer working environment.

How to Train Staff on the Importance of Chemical Metering for Safety and Efficiency

Training staff on the importance of chemical metering is crucial for enhancing both safety and efficiency in industrial settings. The first step in this educational process involves providing a comprehensive overview of what chemical metering is and its role in maintaining precise control over chemical usage. This includes explaining how accurate metering can prevent overuse or wastage of chemicals, which not only improves cost efficiency but also minimizes the environmental impact.

Training staff on the importance of chemical metering is crucial for enhancing both safety and efficiency in industrial settings. The first step in this educational process involves providing a comprehensive overview of what chemical metering is and its role in maintaining precise control over chemical usage. This includes explaining how accurate metering can prevent overuse or wastage of chemicals, which not only improves cost efficiency but also minimizes the environmental impact.

Moreover, hands-on training sessions are essential for employees to directly engage with metering equipment and understand its operational principles. Demonstrations that showcase real-life scenarios can help staff recognize the significance of proper metering practices. Emphasizing the safety aspects, such as how correct dosing reduces the risk of hazardous situations, can foster a culture of responsibility and awareness among workers. By integrating regular assessments and feedback, organizations can ensure that staff remain proficient and alert to the importance of precise chemical handling.

Related Posts

-

7 Essential Tips for Choosing the Right Chemical Injection Pumps

-

Innovative Chemical Injection Solutions at the 138th China Import and Export Fair 2025

-

5 Essential Benefits of Using a Chemical Mixer for Your Manufacturing Process

-

Maximizing Efficiency: How Chemical Feed Pumps Improve Industrial Process Control

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

5 Best Practices for Choosing the Right Chemical Feed Pump