Blog

2026 Top Trends in Chemical Mixer Technology and Innovations?

The chemical mixer industry is evolving rapidly, driven by innovations and shifting market demands. According to a recent report by Grand View Research, the global chemical mixer market is projected to reach $10 billion by 2026, reflecting a compound annual growth rate of 4.5%. These figures highlight the increasing reliance on advanced mixing technologies in various sectors, including pharmaceuticals, food processing, and chemicals.

Industry expert Dr. Susan McCarthy emphasizes the importance of innovation. "The future of chemical mixers lies in integrating smart technologies," she states. This integration allows for enhanced precision and efficiency. As technologies like IoT and AI become common, stakeholders must adapt. Yet, many still rely on outdated systems. Old methods often result in inefficiencies and subpar product quality, raising concerns for manufacturers.

The demand for more sustainable and energy-efficient chemical mixers is also on the rise. Companies are now faced with the challenge of balancing performance with environmental responsibilities. Innovative designs must not only meet functional requirements but also minimize environmental impact. This ongoing transformation poses a crucial question: How will the industry navigate these changes while maintaining quality and efficiency?

Emerging Technologies in Chemical Mixer Design for 2026

In 2026, the chemical mixer technology landscape will see exciting innovations. One key aspect is the rise of smart mixers. These machines utilize AI to monitor mixing processes in real-time. They can adjust parameters automatically, ensuring a more consistent product. By optimizing energy consumption, these mixers also reduce waste. However, integrating AI can pose challenges, especially in legacy systems.

Another emerging trend is modular mixer designs. This approach allows for easy customization and quick upgrades. Manufacturers can adapt mixers to different requirements without complete overhauls. Modularity can enhance efficiency but also requires careful planning during the design phase. Ensuring compatibility among modules can be tricky, and some engineers might overlook this detail.

Sustainability remains a focus. Innovations in materials used for mixers will likely increase. For instance, biodegradable components can replace traditional plastics. While these materials are better for the environment, they might not yet meet durability standards. This creates a dilemma for manufacturers aiming for green solutions. Balancing sustainability and performance is not straightforward. Engineers must strive to meet both goals effectively.

Sustainability Trends in Chemical Mixing Processes and Equipment

Sustainability has become a primary focus in chemical mixing technology. The industry is increasingly adopting eco-friendly practices. New methods are being developed to reduce energy consumption in mixers. This shift is not just about compliance; it’s about innovation and responsibility.

Advanced materials are being utilized to improve efficiency. These materials can withstand high temperatures while minimizing waste. However, many mixers still rely on outdated technology. Upgrading these systems presents a challenge for many manufacturers. The risk of disrupting production can deter investment in greener options.

Additionally, the use of digital technologies for monitoring is on the rise. These tools can optimize mixing processes, reducing excess materials. Yet, some organizations struggle with data integration. They face hurdles in effectively utilizing this technology. This inconsistency in adoption highlights the complexities within the industry. It’s clear that while progress is being made, much remains to be addressed.

Automation and Control Innovations in Mixer Technology

The landscape of mixer technology is evolving rapidly, particularly in automation and control. Innovations in these areas are reshaping how industries operate. Advanced sensors are becoming standard, providing real-time data. This allows for precise adjustments and improved consistency in mixing processes. Operators can monitor parameters like viscosity and temperature far better than before.

However, this advancement comes with challenges. Many facilities face integration issues. They may not have the infrastructure needed to support these new technologies. Data overload can also be a concern, making it difficult to differentiate essential information from noise. Additionally, training workers on new automated systems is often overlooked. A skilled workforce is crucial to harness the full potential of these innovations.

Robust control algorithms are being developed, optimizing production efficiency. These algorithms help minimize waste and energy consumption. Yet, the complexity of programming them can deter smaller operations. It’s essential to find a balance between embracing new technologies and maintaining practicality. Each innovation can spark excitement, but consideration of existing systems is vital. After all, not every solution fits every scenario.

2026 Top Trends in Chemical Mixer Technology and Innovations

| Trend | Description | Impact on Industry | Key Innovations |

|---|---|---|---|

| Smart Mixer Technology | Integration of IoT devices for real-time monitoring and control. | Enhances efficiency and reduces downtime in production processes. | Sensors, AI algorithms, and cloud connectivity. |

| Energy Efficient Designs | Mixers designed to consume less energy while maintaining performance. | Lowers operational costs and supports sustainability goals. | Variable speed drives and advanced motor designs. |

| Advanced Materials | Incorporation of new materials for improved durability and corrosion resistance. | Extends the lifespan of mixers and reduces maintenance frequency. | Ceramic coatings, composite materials, and stainless steel innovations. |

| Modular Mixer Designs | Flexible, modular mixing systems that can easily be adapted for different applications. | Increases adaptability and reduces the need for multiple machines. | Interchangeable parts and customizable configurations. |

| Enhanced Safety Features | Implementation of advanced safety systems and controls. | Improves operator safety and compliance with regulations. | Automated shut-off systems and safety interlocks. |

Enhancements in Mixer Efficiency through Advanced Materials

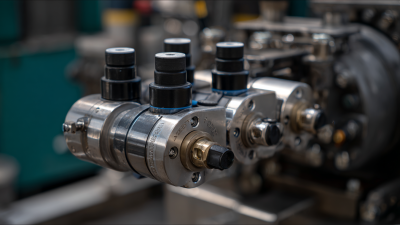

In 2026, the chemical mixing industry is witnessing significant advancements. One key area is the use of advanced materials to boost mixer efficiency. Reports indicate that mixers equipped with high-performance materials can improve mix consistency by up to 30%. This increase significantly enhances product quality and reduces waste.

These materials are designed to withstand harsh conditions. They also offer resistance to corrosion, wear, and chemical reactions. Such properties are crucial in maintaining a long lifespan for mixers, ultimately lowering maintenance costs. Manufacturers are re-engineering traditional designs to incorporate these materials. This not only improves durability but also optimizes energy consumption.

Tips: When selecting mixers, consider materials carefully. Look for options that promise both strength and longevity. Regular maintenance remains essential, even with advanced materials. Monitor wear and tear to ensure your mixer continues to perform effectively. The industry is evolving, and keeping up with trends can significantly impact your operational efficiency.

2026 Top Trends in Chemical Mixer Technology and Innovations

This chart illustrates the advancements in mixer efficiency driven by innovative materials and technology in 2026. The data reflects the percentage improvement in efficiency across various mixer types.

Future Applications of Chemical Mixers in Various Industries

In 2026, chemical mixers will evolve significantly across industries. The food and beverage sector will rely on mixers for enhanced flavors and textures. Innovations will include automated systems that ensure consistency. Precision in ingredient proportions will reduce waste significantly.

In pharmaceuticals, the role of mixers will be crucial for drug formulation. Advanced mixers will allow for more effective blending of powders. This can improve drug efficacy. Enhanced mixing technology could minimize errors. However, equipment maintenance will still be a challenge for many companies.

Tips: Monitor mixer performance regularly. Small adjustments can lead to big improvements. Also, consider staff training on new technologies. A knowledgeable team will maximize efficiency and minimize downtime.

Related Posts

-

5 Essential Benefits of Using a Chemical Mixer for Your Manufacturing Process

-

Ultimate Guide to Choosing the Right Chemical Mixer: Key Features and Industry Insights

-

Essential Tank Mixer Guide: Mastering Mixing Techniques for Optimal Results

-

2025 Top Mixer Pump Insights Benefits Usage and Buying Guide

-

How to Select the Right Injection Pumps for Your Industrial Needs

-

Top Pump Systems for Efficient Water Management Solutions