Blog

Top 5 Tank Mixers to Boost Your Efficiency in 2025

In the ever-evolving landscape of industrial processing, the efficiency of tank mixers plays a critical role in enhancing production capabilities. According to a recent report by MarketsandMarkets, the tank mixer market is expected to grow by 5.3% annually, reaching a value of over $3 billion by 2025. This growth signals a rising demand for advanced mixing technologies that not only improve operational efficiency but also ensure consistent product quality across various sectors, including chemical, pharmaceutical, and food processing industries.

Industry expert Dr. Emily Henderson, a leading authority in fluid dynamics, emphasizes the importance of selecting the right tank mixer, stating, “The efficiency of a process can significantly hinge on the type of mixer employed; choosing the right one can lead to a substantial reduction in processing times and operational costs.” With this in mind, businesses are increasingly looking towards innovative tank mixers that leverage cutting-edge technology to streamline operations and adapt to dynamic market requirements.

As we move forward into 2025, understanding the top tank mixers that can elevate operational efficiency will be crucial for industry players seeking a competitive edge. This guide highlights the top five tank mixers to consider, focusing on their unique features, benefits, and how they align with current industry trends, ultimately equipping organizations with the insights needed to make informed decisions.

Top Trends in Tank Mixer Technology for 2025

As we look ahead to 2025, the tank mixer technology is poised for significant advancements that will enhance operational efficiency across various industries. One of the key trends is the integration of IoT (Internet of Things) capabilities. With more tanks being fitted with IoT sensors, operators can monitor real-time data regarding viscosity, temperature, and flow rates. A report by Research and Markets indicates that the IoT-enabled tank mixer market is expected to grow at a compound annual growth rate (CAGR) of 12.5% from 2023 to 2028, showcasing the sector's commitment to innovation.

Another notable trend is the move towards energy-efficient mixers. The demand for sustainable solutions is driving manufacturers to design mixers that consume less power while maintaining optimal performance levels. An analysis from Markets and Markets highlights that energy-efficient mixing technologies are projected to account for approximately 40% of total tank mixer sales by 2025, emphasizing the industry's shift towards sustainability. Alongside this, advancements in materials science will lead to the creation of more durable and recyclable components, allowing for longer-lasting mixers that can withstand harsh operational environments.

Key Features to Look for in Modern Tank Mixers

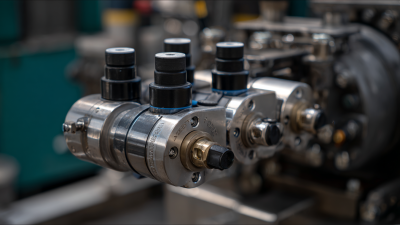

When selecting a tank mixer in 2025, prioritizing key features can significantly enhance your operational efficiency. Modern tank mixers are designed with advanced engineering to ensure optimal mixing performance. Look for mixers that offer variable speed control. This feature allows you to adjust the mixing intensity depending on the specific viscosity of the materials, leading to better consistency in your products.

Another crucial aspect to consider is the material of construction. Stainless steel mixers are ideal for their durability and resistance to corrosion, while specialized coatings may be necessary for harsher environments. Additionally, opt for mixers that come equipped with energy-efficient motors. These not only reduce your energy consumption but also cut operational costs in the long run.

Tip: Always assess the ease of maintenance when choosing a tank mixer. Models that are easy to disassemble and clean can save you valuable production time. Moreover, investing in mixers with integrated monitoring systems can help detect performance issues early, allowing for timely interventions that prevent downtime. Keep these features in mind to boost your efficiency effectively in 2025.

How Tank Mixers Can Increase Operational Efficiency

In the ever-evolving landscape of industrial operations, tank mixers play a pivotal role in enhancing efficiency. According to a recent report by the Mixing Technology Association, efficient mixing processes can lead to a 30% reduction in cycle times, significantly increasing productivity in industries ranging from chemical manufacturing to food processing. As operations strive for higher throughput and lower costs, the implementation of advanced tank mixers can streamline processes, reduce energy consumption, and optimize resource utilization.

Moreover, a study published in the Journal of Industrial Mixing highlights that facilities employing modern tank mixer technology report an 18% improvement in product consistency and quality. This not only helps in minimizing waste but also ensures compliance with stringent quality standards, which is crucial in highly regulated sectors. The ability to achieve uniform mixtures rapidly enables companies to respond more effectively to market demands, positioning them for competitive advantage in 2025 and beyond. Investing in the right tank mixing solutions is not just a matter of operational enhancement; it is a strategic move towards long-term sustainability and profitability.

Top 5 Tank Mixers to Boost Your Efficiency in 2025

| Mixer Model | Mixing Capacity (liters) | Power (kW) | Efficiency Rating (%) | Noise Level (dB) |

|---|---|---|---|---|

| Model A | 500 | 5 | 85 | 70 |

| Model B | 1000 | 7.5 | 90 | 68 |

| Model C | 750 | 6 | 87 | 69 |

| Model D | 1200 | 10 | 92 | 65 |

| Model E | 1500 | 15 | 95 | 72 |

Best Practices for Tank Mixer Maintenance and Longevity

Maintaining tank mixers is crucial for ensuring their efficiency and longevity in various industries. According to a report by Research and Markets, improper maintenance can reduce equipment lifespan by up to 30%. Regular maintenance practices, such as routine inspections and timely replacements of worn-out parts, are essential for optimizing the performance of these mixers. It is recommended to develop a preventive maintenance schedule that includes checking the motor function, seal condition, and impeller wear at least every six months. This proactive approach not only minimizes unexpected downtime but also enhances the overall productivity of mixing operations.

Moreover, industry experts emphasize the importance of proper cleaning and lubrication. A study by the Mixing Equipment Manufacturers Association (MEMA) highlighted that mixers that undergo regular lubrication can last up to 50% longer than those that do not. Additionally, cleaning the mixer after every batch prevents the buildup of residues that can affect mixing efficiency and product quality. Implementing these best practices not only boosts the operational lifespan of tank mixers but also contributes to significant cost savings in repair and replacement expenditures, making it a vital aspect for industries relying on these essential machines.

Cost-Benefit Analysis of Upgrading Your Tank Mixing Equipment

Upgrading your tank mixing equipment can lead to significant improvements in operational efficiency and productivity. Conducting a cost-benefit analysis is essential for making informed decisions. Consider factors such as increased mixing speed and uniformity, which can directly impact product quality and reduce waste. The initial investment in new technology might seem daunting, but the long-term savings from improved performance often justify the expense.

**Tips:** When evaluating new mixers, pay close attention to their energy efficiency ratings. Energy-saving models may have a higher upfront cost but can lead to substantial savings in utility expenses over time. Additionally, assess the maintenance requirements of the mixers; equipment that is easier to maintain can save money and downtime in the long run.

Another critical aspect to consider is the scalability of your tank mixers. As your production volume grows, the flexibility to upgrade or scale current equipment can prevent costly interruptions in your operations. Investing in versatile mixers that can adapt to varying production needs will enhance your efficiency well into the future.

Top 5 Tank Mixers to Boost Your Efficiency in 2025

The chart above illustrates the cost-benefit ratio for the top five tank mixers anticipated for use in 2025. A higher ratio indicates greater efficiency and return on investment, underscoring the importance of selecting the right equipment for your mixing needs.

Related Posts

-

Innovative Tank Mixer Applications Across Various Industries

-

Essential Tank Mixer Guide: Mastering Mixing Techniques for Optimal Results

-

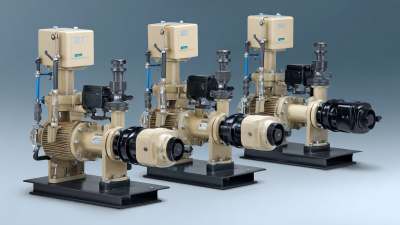

How to Choose the Right Industrial Pumps for Your Manufacturing Needs

-

Innovative Solutions for Industrial Pumps to Enhance Efficiency and Reduce Costs

-

7 Essential Tips for Choosing the Right Chemical Injection Pumps

-

How to Select the Right Injection Pumps for Your Industrial Needs