Blog

2025 Top Mixer Pump Insights Benefits Usage and Buying Guide

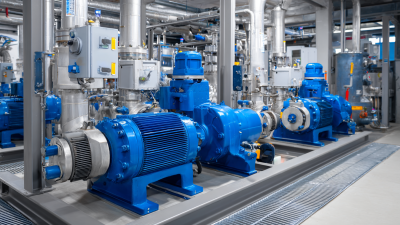

In the ever-evolving world of construction and industrial operations, the mixer pump stands out as a vital tool. This device combines fluid and solid materials, making it essential for various applications. Understanding its capabilities can enhance efficiency.

Mixer pumps are prominent in tasks like concrete mixing and slurry transportation. Their design allows for quick and effective blending of materials. However, not all mixer pumps are created equal. Selecting the right one requires careful consideration of your specific needs.

Many users overlook important factors. The size, power, and capacity of a mixer pump can significantly impact its performance. Investing in the wrong pump may lead to waste and lost time. Reflecting on your requirements will guide you in making better choices. The insights offered in this guide aim to shed light on optimizing your experience with mixer pumps.

2025 Top Mixer Pump Overview and Market Trends

In 2025, the mixer pump market is evolving rapidly. New machines are becoming more versatile and efficient. These pumps are essential for many construction projects. They mix materials like concrete or plaster directly on-site. This leads to significant time savings. However, not all pumps are created equal.

When looking to buy a mixer pump, consider specific features. Power and capacity are critical factors. A machine with higher capacity can handle larger jobs. Check the pump’s mixing efficiency, too. Some designs mix better than others, resulting in a more consistent final product. Don’t forget ease of transport. A heavy mixer can be cumbersome on job sites.

Tips: Test the mixer pump before purchase. Hands-on experience can reveal issues not seen online. Also, consult with operators; their insights are invaluable. Keep in mind that customer reviews may not always be reliable. Verify claims through direct research. The market is competitive. Make informed choices to avoid regrets later.

Key Features and Specifications of Mixer Pumps

When considering mixer pumps, understanding their key features is essential. Mixer pumps are designed for blending materials efficiently. They typically include a robust motor that powers the mixing process. The capacity varies, often influenced by the tank size and pump design. This flexibility allows for different applications, from small projects to large-scale operations.

Efficiency is a crucial aspect. A well-designed mixer pump minimizes energy consumption while maximizing output. While many pumps might claim high efficiency, not every model delivers. It's wise to consider actual user reviews and performance metrics before making a decision.

Materials used in construction also matter. Many mixer pumps are made from stainless steel or durable plastics. These materials provide longevity and resistance to corrosion. However, buyers should be aware of potential trade-offs. In some cases, lighter materials may compromise stability.

With various features and specifications to consider, it’s important to weigh your options carefully. Take the time to reflect on your specific needs. Understanding these elements can lead to a more informed purchase.

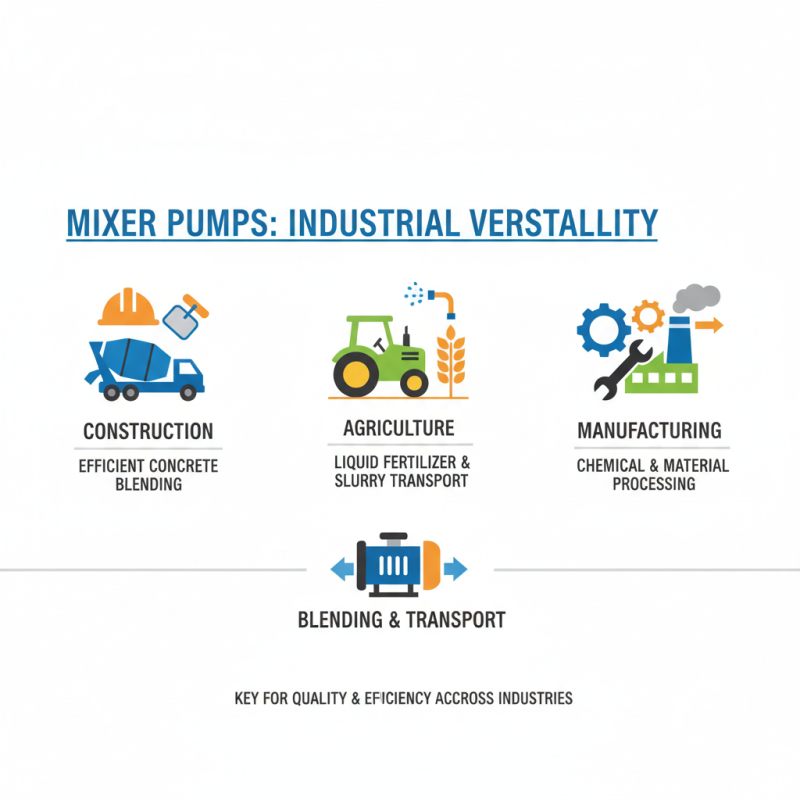

Advantages of Using Mixer Pumps in Various Applications

Mixer pumps are versatile tools used across various industries. Their ability to blend and transport liquid materials makes them invaluable in construction, agriculture, and manufacturing. In construction, they mix concrete efficiently, ensuring a uniform consistency that enhances the structural integrity of the work. This adaptability is crucial, especially in large projects where time and quality are equally important.

In agriculture, mixer pumps mix fertilizers and pesticides with water for effective application. This uniform mixing allows for better coverage and helps prevent over-application, which can harm crops. Furthermore, in manufacturing, these pumps contribute to producing paints, adhesives, and other materials. Their seamless operation can increase productivity, reducing labor costs that often accompany manual mixing.

However, using mixer pumps is not without challenges. Operators need proper training to avoid inconsistencies in mixing. Regular maintenance is essential to ensure optimal performance. Over time, wear and tear can affect efficiency, potentially leading to costly downtime. Awareness of these issues can help users maximize the benefits of mixer pumps while minimizing setbacks.

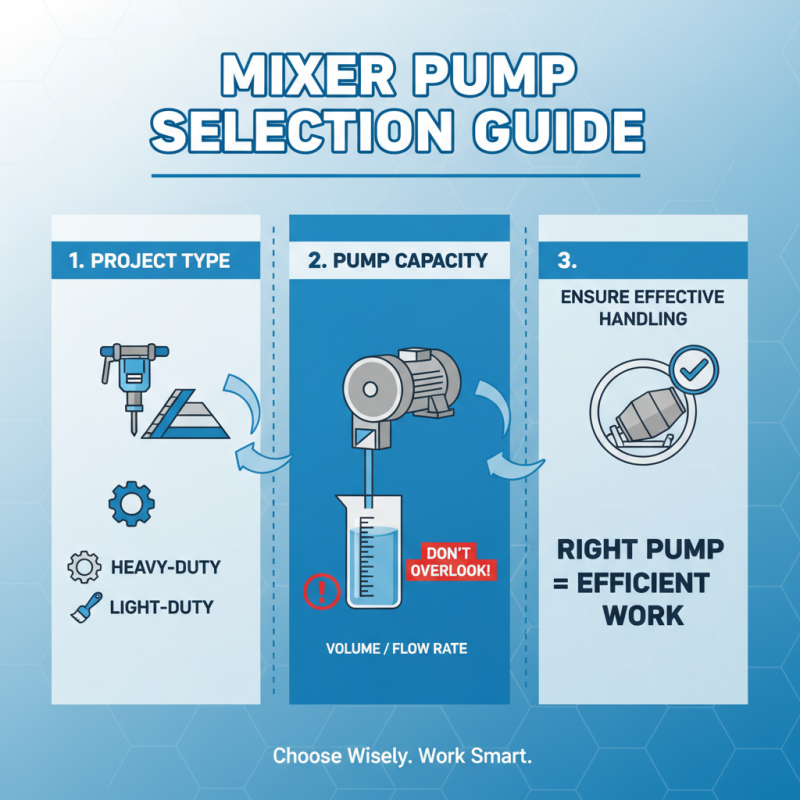

Guidelines for Selecting the Right Mixer Pump

When selecting the right mixer pump, consider your specific needs. Do you need it for heavy-duty projects or lighter applications? Sometimes, users overlook pump capacity. Ensure the pump can handle the required volume effectively.

Pay attention to the mixing efficiency. A well-designed pump should create uniform mixtures without any separation. However, achieving this balance can be challenging. Some users may find their mixtures inconsistent, revealing the need for a thorough evaluation of their pump choice.

Don’t forget to assess portability. If you need to move the pump between sites, weight matters. Compact models are easier to transport, but they might compromise on power. Finding a mix that suits your workflow is essential. Consider testing different models before making a final decision.

Maintenance Tips to Ensure Optimal Performance of Mixer Pumps

Mixer pumps are essential in various industries, from construction to manufacturing. Regular maintenance is crucial for optimal performance. Neglecting maintenance can lead to inefficiencies and costly repairs. According to industry reports, improper pump upkeep costs businesses over $5 billion annually. Understanding how to care for mixer pumps can significantly reduce these expenses.

Tip 1: Regularly check the oil levels. Maintaining proper lubrication prevents overheating and wear. Low oil levels can lead to serious damage, often unnoticed until it's too late. Be proactive about this simple task.

Tip 2: Inspect seals and gaskets frequently. A worn seal can cause leaks and pressure loss, reducing pump efficiency. Industry studies show that leaks can decrease operational efficiency by 10-15%. Catching these issues early can save money.

Tip 3: Clean the intake filters regularly. Clogged filters can restrict flow and increase strain on the pump. Regular cleaning can improve efficiency and lifespan. Many users overlook this step, only to find reduced performance later on.

These maintenance tips can enhance the longevity and functionality of your mixer pump. Taking the time to ensure regular check-ups will lead to smoother operations and can prevent unexpected breakdowns.

Related Posts

-

How to Choose the Best Pump Accessories for Optimal Performance and Efficiency

-

Understanding the Role of Chemical Feed Pumps in Modern Industrial Applications

-

7 Essential Tips for Choosing the Right Chemical Mixer for Your Industry Needs

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

2025 Top Metering Pump Innovations for Precision Fluid Control