Blog

Top 10 Chemical Metering Solutions for Accurate and Efficient Measurement

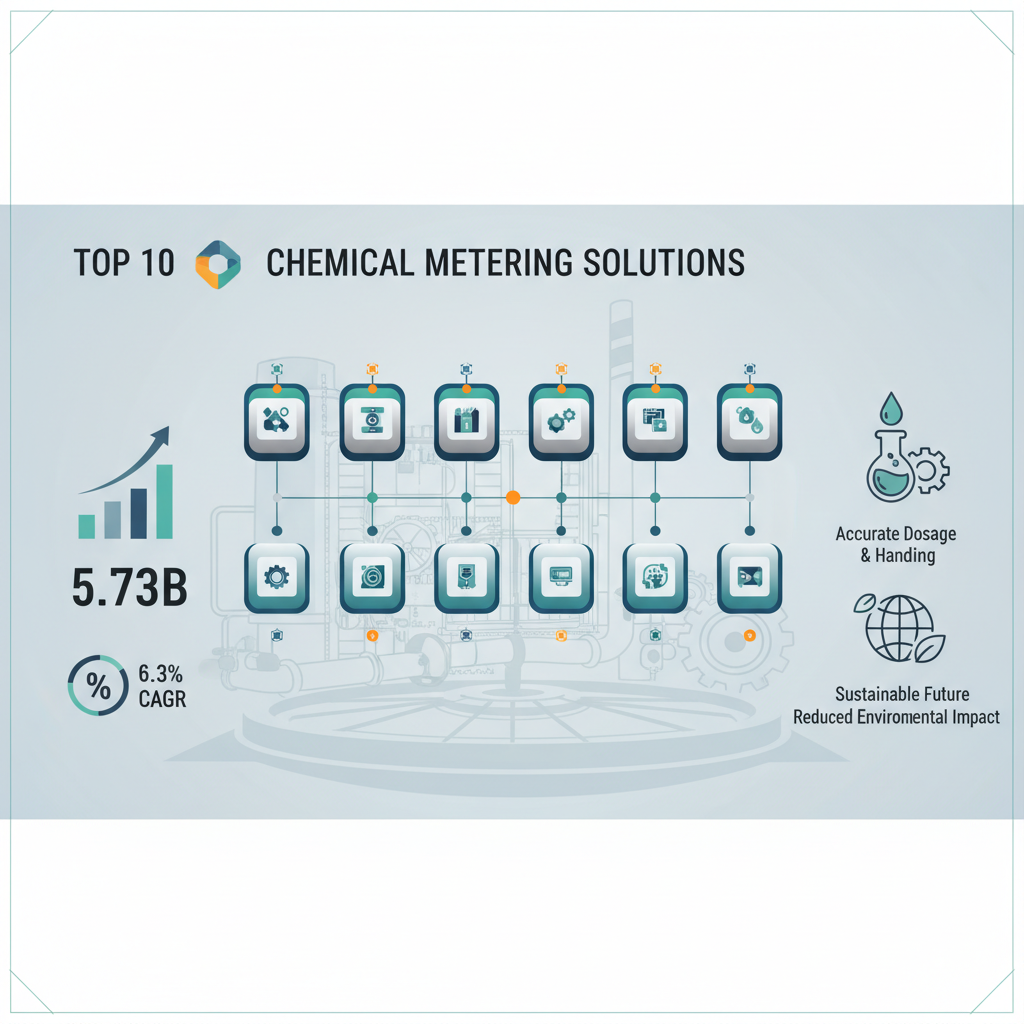

In today's industrial landscape, the precision of chemical metering is paramount for ensuring safety, efficiency, and compliance across various sectors, including pharmaceuticals, water treatment, and chemical manufacturing. According to a report by MarketsandMarkets, the global chemical metering pumps market is projected to reach USD 5.73 billion by 2026, growing at a CAGR of 6.3% from 2021 to 2026. This significant growth underscores the increasing demand for advanced technologies that facilitate accurate dosage and effective chemical handling.

Experts in the field emphasize the critical role that reliable metering solutions play in operational excellence. As noted by Dr. Emily Roberts, a leading authority on chemical processing technologies, "Accurate chemical metering is not only about measurement; it’s about ensuring optimal performance and minimizing environmental impact." With the rise in regulatory scrutiny and the need for sustainable practices, industries are compelled to adopt cutting-edge metering solutions that guarantee precise delivery and reduce waste.

This article delves into the top 10 chemical metering solutions that stand out for their accuracy, efficiency, and innovative designs. By exploring these solutions, organizations can better navigate the complexities of chemical handling, optimize their processes, and contribute to a safer and more sustainable future.

Essential Features of Chemical Metering Solutions for Accuracy

In the rapidly growing metering pumps market, projected to reach USD 9.1 billion by 2030, the importance of accurate and efficient chemical metering solutions cannot be overstated. Essential features of these solutions include precision dosing capabilities, which are vital for applications across various industries such as

water treatment, pharmaceuticals, and food and beverage.

Advanced metering pumps equipped with digital controls can provide real-time feedback and adjustments, ensuring that the correct chemical dosage is delivered consistently.

Moreover, another critical feature is the ability to handle a wide range of viscosities and fluid types. This versatility is crucial for companies that require reliable performance in diverse operating conditions.

In addition, incorporating smart technology such as IoT connectivity can enhance operational efficiency, allowing for remote monitoring and maintenance, thus reducing downtime and improving overall productivity.

Industry insights underscore that organizations prioritizing these features can achieve significant cost savings and improved accuracy in their chemical handling processes.

Types of Chemical Metering Technologies and Their Applications

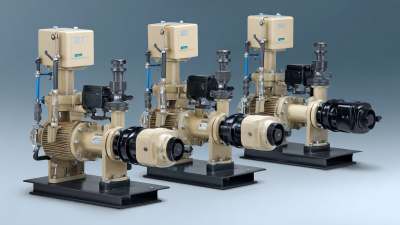

When it comes to chemical metering technologies, various types offer distinct advantages based on specific applications. Positive displacement pumps provide precise flow measurement, making them ideal for dosages in industries such as pharmaceuticals and food processing. Alternatively, electromagnetic flow meters are renowned for their accuracy in conductive fluids, making them suitable for water treatment facilities and chemical processing plants.

Tips: Ensure that the selected metering technology aligns with the fluid characteristics, such as viscosity and conductivity, to maximize measurement accuracy.

Another notable metering solution is the mass flow meter, which directly measures the mass of fluid passing through it and is particularly effective in the oil and gas sector. Additionally, ultrasonic flow meters are increasingly popular in various industries due to their non-invasive nature and ability to measure flow rates without altering the flow path.

Tips: Regular calibration and maintenance of your metering devices are essential to ensure long-term efficiency and reliability in measurements.

Top 10 Chemical Metering Solutions for Accurate and Efficient Measurement

| Technology Type | Measurement Principle | Accuracy (%) | Flow Range (L/h) | Typical Applications |

|---|---|---|---|---|

| Positive Displacement Meters | Volume Displacement | ±0.5 | 0.1 - 5000 | Food & Beverage, Oil |

| Electromagnetic Flow Meters | Faraday's Law | ±1.0 | 1 - 3000 | Water Treatment, Chemical Processing |

| Ultrasonic Flow Meters | Transit Time | ±1.5 | 0.5 - 5000 | Pharmaceuticals, Water Distribution |

| Corrosion-Resistant Turbine Meters | Turbine Rotation | ±0.5 | 0.2 - 4000 | Chemical Processing, Paint |

| Mass Flow Meters | Coriolis Effect | ±0.1 | 0.1 - 10000 | Oil, Chemicals, Food |

| Vortex Flow Meters | Vortex Shedding | ±0.5 | 1 - 20000 | Steam, Water, Gas |

| Turbine Flow Meters | Rotational Speed | ±1.0 | 5 - 5000 | Oil, Water, Chemicals |

| Diaphragm Flow Meters | Diaphragm Deflection | ±2.0 | 0.1 - 3000 | Fuel, Water Treatments |

| Rotary Vane Flow Meters | Vane Rotation | ±0.5 | 0.5 - 10000 | Hydraulic, Oil, Chemical |

Factors Influencing the Selection of Chemical Metering Solutions

When selecting chemical metering solutions, several critical factors come into play to ensure accuracy and efficiency in measurement. One of the primary considerations is the type of chemical being measured. Different chemicals have unique properties, such as viscosity, temperature sensitivity, and corrosiveness, which can influence the performance of a metering system. For instance, heavy or viscous chemicals may require specialized pumps to achieve precise flow rates without clogging or damaging the equipment.

Another vital factor is the operating environment. Chemical metering solutions must withstand varying temperature and pressure conditions, as well as potential exposure to hazardous materials. Therefore, assessing compatibility with the surrounding environment is crucial to maintaining equipment integrity and ensuring safety. Additionally, the availability of maintenance and support services can significantly impact the long-term reliability of the metering solution. Vendors that offer robust customer support and maintenance options provide peace of mind, allowing users to focus on efficient operation while minimizing downtime due to unforeseen issues.

Top Recommended Brands for Chemical Metering Devices in the Market

When it comes to chemical metering devices, selecting the right brand is crucial for achieving accurate and efficient measurements in various applications. In today’s market, several top manufacturers stand out for their commitment to innovative technology and reliability. Leading brands offer a range of solutions, from precision pumps to advanced metering systems that ensure optimal performance in chemical processing, agriculture, and water treatment industries.

Among the recommended brands, some are known for their durability and user-friendly interfaces, making them ideal for both small-scale and industrial applications. These brands prioritize not only accuracy but also the safety of users through features that minimize risks associated with handling hazardous chemicals. By focusing on the needs of different sectors, these brands consistently deliver metering solutions that enhance operational efficiency and ultimately lead to better outcomes in chemical handling and measurement processes.

Future Trends in Chemical Metering Solutions for Industry Efficiency

As industries continue to evolve, the demand for precise chemical metering solutions is becoming increasingly critical. Future trends suggest a shift towards smart metering technologies that integrate IoT, enabling real-time monitoring and data analytics. These advancements not only enhance measurement accuracy but also streamline operations, allowing companies to optimize their processes for greater efficiency. With the ability to track chemical usage instantaneously, businesses can reduce waste and lower operational costs.

**Tips:** When considering a chemical metering solution, prioritize systems that offer scalability and compatibility with existing technologies. Ensure that the chosen solution can be easily integrated into your current infrastructure, facilitating a smoother transition and minimizing downtime.

Moreover, emerging technologies such as artificial intelligence and machine learning are playing a significant role in predictive maintenance and troubleshooting. By analyzing historical data, these technologies can anticipate potential issues before they arise, reducing the risk of downtime and ensuring continuous operation. Industries that adopt these advanced metering solutions will stand at the forefront of efficiency and innovation.

**Tips:** Regular training for staff on the latest metering technologies is essential. Equip your team with the knowledge to effectively use advanced systems, which will increase overall proficiency and enhance operational efficiency.

Related Posts

-

2025 Top 5 Chemical Metering Solutions for Precision and Efficiency

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

7 Essential Tips for Choosing the Right Chemical Injection Pumps

-

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety

-

What is a Chemical Pump? Understanding Types, Uses, and Benefits for Your Industry

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency