Blog

2025 Top Chemical Metering Pump System Insights and Innovations

In the rapidly evolving landscape of industrial applications, the significance of a robust and innovative chemical metering pump system cannot be overstated. As industries increasingly focus on precision, efficiency, and sustainability, the demand for advanced metering solutions that optimize chemical dosing processes has surged. Experts in the field, such as Dr. Emily Chen, a leading authority on fluid dynamics and pump technology, emphasize the critical role of these systems in enhancing operational efficiency. Dr. Chen aptly remarked, "The future of chemical processing relies heavily on the accuracy and reliability offered by modern chemical metering pump systems."

As we look ahead to 2025, the insights and innovations surrounding chemical metering pump systems are set to redefine industry standards. The integration of smart technologies, real-time monitoring, and enhanced automation will not only streamline workflows but also reduce waste and energy consumption. These advancements are not just a response to regulatory demands but also a proactive measure towards achieving greater sustainability in chemical handling and processing.

Furthermore, the importance of adaptability within chemical metering pump systems has never been more critical. Businesses must navigate varying operational environments and stringent compliance requirements, making it essential for these systems to evolve in response to changing demands. As we delve deeper into the insights of 2025, it will be paramount to focus on how emerging technologies can enhance the efficiency and reliability of chemical metering processes, ensuring that industries can meet their challenges head-on.

Global Market Overview of Chemical Metering Pumps in 2025

The global chemical metering pump market is poised for significant growth by 2025, driven by the increasing need for precise and efficient fluid control in various industries such as water treatment, chemical processing, and food and beverage. According to a recent market report, the chemical metering pump segment is expected to witness a compound annual growth rate (CAGR) of over 5% during the forecast period. This growth can be attributed to technological advancements that enhance pump performance, reliability, and sustainability.

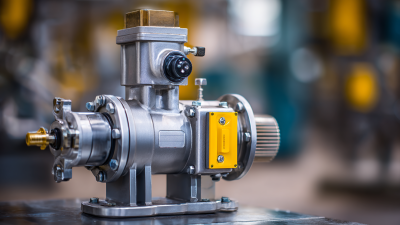

As industries evolve, the demand for smarter and more integrated solutions increases. Innovations such as digital metering systems that utilize IoT technology for real-time monitoring and control will play a pivotal role in improving operational efficiency. Furthermore, enhanced materials used in pump construction are contributing to greater resistance against corrosive substances, thereby extending the lifespan of metering pumps and reducing maintenance costs.

**Tip:** When selecting a chemical metering pump system, consider the total cost of ownership, including initial investment and long-term maintenance. Additionally, compatibility with existing systems and ease of integration can significantly affect efficiency and output quality in the production process.

Key Innovations Driving Efficiency in Metering Pump Technologies

The metering pump industry is experiencing a significant transformation driven by key innovations that enhance efficiency and adaptability. Recent advancements in technology focus on the integration of smart systems and IoT capabilities, enabling remote management and monitoring. According to a report by Global Market Insights, the adoption of smart metering solutions is projected to increase by over 20% annually, driven by the demand for improved precision and reduced operational costs in various chemical applications.

Another noteworthy trend in metering pump technology is the development of advanced materials that enhance durability and resistance to aggressive chemicals. Research from TechSci Research indicates that innovative materials such as ceramic and high-performance polymers can extend the lifespan of metering pumps by up to 30%. These materials not only provide better performance but also reduce maintenance costs and downtime, contributing to greater overall efficiency.

**Tip:** To maximize the benefits of modern metering pump systems, consider integrating predictive maintenance strategies. By leveraging data analytics, operators can predict potential failures before they occur, ensuring uninterrupted operation and reducing costly repairs.

Furthermore, energy efficiency is becoming increasingly important, and new designs focus on minimizing energy consumption while maintaining high performance. Enhanced control algorithms and variable speed drives are among the innovations that optimize pump operation, allowing for dynamic adjustments based on real-time demand. As industries strive for sustainability, selecting energy-efficient metering pump solutions can significantly lower environmental impact and operational costs.

**Tip:** Regularly assess your pump system for energy performance metrics to identify areas for improvement. This proactive approach not only boosts efficiency but also aligns with growing sustainability initiatives in the chemical sector.

2025 Top Chemical Metering Pump System Insights and Innovations

| Innovation | Description | Efficiency Improvement (%) | Application Areas |

|---|---|---|---|

| Smart Metering | Integration of IoT technologies to monitor and control pump operations remotely. | 30% | Chemical Processing, Water Treatment |

| Variable Speed Drives | Adjustment of flow rates based on real-time demand, improving energy consumption. | 20% | Pharmaceuticals, Food Processing |

| Advanced Materials | Use of corrosion-resistant materials to extend pump life and reduce maintenance. | 25% | Mining, Pulp and Paper |

| Digital Twin Technology | Simulation of pump systems to predict performance and optimize operations. | 15% | Oil & Gas, Waste Management |

Emerging Trends in Chemical Metering Pump Applications and Usage

The chemical metering pump industry is undergoing significant transformation, driven by technological advancements and increasing demand across various sectors. Recent market research indicates that the global chemical metering pump market is expected to reach approximately USD 6.28 billion by 2025, growing at a CAGR of around 5.3% from 2020. This growth highlights the rising adoption of advanced metering systems that enhance efficiency and accuracy in chemical dosing applications, particularly within water treatment, pharmaceuticals, and food processing industries.

One of the emerging trends in chemical metering pump applications is the integration of smart technology and IoT capabilities. With the advent of smart pumps, manufacturers are now able to provide real-time monitoring and control over dosing processes. A study by the Research Institute of Petroleum Industry shows that the use of IoT-driven metering solutions can reduce operating costs by up to 15% while improving chemical usage efficiency. Furthermore, the increasing emphasis on sustainability and environmental responsibility is pushing industries to adopt more precise metering solutions that minimize waste and enhance resource management.

Additionally, advancements in materials and engineering have led to the development of more durable and versatile pump designs. For instance, the use of corrosion-resistant materials is becoming increasingly popular, significantly extending the lifespan of pumps in harsh chemical environments. Industry reports suggest that the adoption of such materials has grown by 20% in the last few years, driven by regulatory pressures and the need for reliable system performance. These innovations are reshaping the landscape of chemical metering pumps, ensuring they meet the evolving demands of a variety of applications effectively.

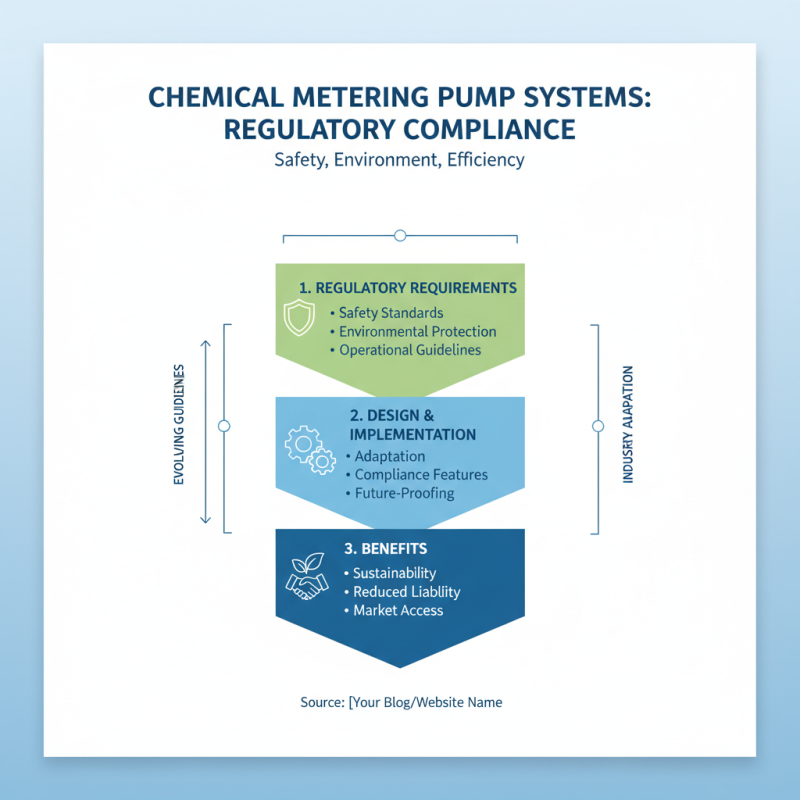

Regulatory Impacts on Chemical Metering Pump Design and Implementation

The design and implementation of chemical metering pump systems are significantly influenced by regulatory requirements that ensure safety, environmental protection, and operational efficiency. As governments and regulatory bodies impose stricter guidelines regarding the handling and use of chemicals, manufacturers must adapt to remain compliant. This emphasis on regulatory adherence necessitates that the design phase incorporates features that not only meet existing standards but also anticipate future changes, thus promoting sustainability and reducing potential liabilities.

Moreover, regulations often dictate the materials and technologies employed in pump systems. For instance, standards may require pumps to be constructed from corrosion-resistant materials that can withstand harsh chemicals, thus ensuring long-term performance and minimizing risks of leaks or failures. Additionally, impact assessments and documentation are often necessary to validate compliance, which can influence the overall design and functionality of metering systems. As a result, companies must invest in innovative solutions that align with these regulations while still aiming to improve efficiency and reduce operational costs. By understanding and integrating regulatory impacts into their design and implementation processes, manufacturers can enhance the reliability and effectiveness of chemical metering pump systems, ultimately leading to safer operational environments.

Sustainability Initiatives and Their Influence on Metering Pump Systems

Sustainability initiatives are reshaping the landscape of chemical metering pump systems, pushing manufacturers to innovate and adopt greener practices. These initiatives focus on reducing energy consumption, minimizing waste, and using eco-friendly materials, all while maintaining high operational efficiency. As industries increasingly recognize the importance of sustainability, metering pump systems are evolving to incorporate technologies that not only deliver precise chemical dosing but also align with environmental goals.

Tip: When evaluating metering pump systems for sustainability, consider options that emphasize energy efficiency and low emissions. These can help reduce operational costs and decrease your organization's carbon footprint.

Moreover, advancements in smart technology play a crucial role in this transformation. Integrating IoT capabilities allows for real-time monitoring and control of pump systems, enabling businesses to optimize performance and reduce resource usage. Such innovations make it easier to align with sustainability goals, providing greater transparency in operations.

Tip: Embrace system automation and real-time data analytics to enhance the efficiency of your chemical processes. This approach can significantly contribute to sustainability efforts by allowing for timely adjustments and reductions in chemical waste.

2025 Insights on Sustainability Initiatives in Metering Pump Systems

Related Posts

-

2025 Guide to Choosing the Best Chemical Injection Pumps for Your Needs

-

10 Unique Metering Pump Types You Should Know About

-

Understanding the Benefits of Chemical Metering Pumps in Modern Water Treatment Systems

-

Understanding the Role of Industrial Metering Pumps in Modern Manufacturing Processes

-

How to Choose the Right Types of Pumps for Your Industrial Needs: A Comprehensive Guide

-

2025 Top 5 Chemical Metering Solutions for Precision and Efficiency