Blog

2025 Top 5 Chemical Metering Solutions for Precision and Efficiency

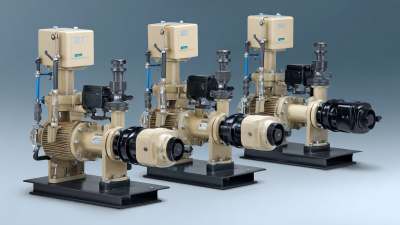

In the rapidly evolving landscape of industrial operations, precision in chemical metering has emerged as an indispensable component for enhancing efficiency and achieving optimal performance. According to a recent report by MarketsandMarkets, the global chemical metering pump market is projected to grow from $3.5 billion in 2020 to $5.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth is driven by increasing demand for accurate dosing in sectors such as water treatment, oil and gas, and food and beverage, where even minor discrepancies can lead to significant operational inefficiencies.

Experts in the field underscore the importance of adopting advanced chemical metering solutions. Dr. James McAlister, a leading authority in chemical engineering, stated, “The future of chemical dosing systems lies in embracing smart technologies that ensure precision and reliability.” This sentiment resonates strongly in an era where digital transformation and automation are reshaping industry standards. As manufacturers strive to become more competitive, understanding and implementing the best chemical metering solutions will be critical not only for compliance but also for achieving sustainable operational practices.

In light of these trends, we will explore the top five chemical metering solutions for 2025, highlighting technologies that promise to redefine efficiency and precision. As industries adapt to these innovations, the emphasis on reliable chemical metering will undoubtedly play a vital role in their success.

Top Trends in Chemical Metering Solutions for Enhanced Precision in 2025

The chemical metering solutions industry is poised for significant growth, with the global market expected to reach approximately $360.73 million by 2025, escalating to $615.6 million by 2035. This growth reflects a compound annual growth rate (CAGR) of 5.5%, driven by the increasing demand for precision and efficiency in chemical processing applications. As businesses seek to optimize operations, advancements in metering technology are becoming essential for ensuring accurate chemical dosing, which is crucial for maintaining quality and safety in production processes.

Simultaneously, the hydraulic metering pump market is also on an upward trajectory, projected to attain a market size of $874.32 million by 2025 and further expand to $1.57 billion by 2035, representing a CAGR of 6.0%. As industries focus on optimizing fluid management and minimizing wastage, the evolution of hydraulic pumps with enhanced metering capabilities is set to play a key role. The integration of smart technologies in these solutions promises improved automation and precision, catering to the growing regulatory demands and efficiency standards in various sectors. Such trends underscore the importance of staying ahead in technology, with enhanced chemical metering solutions at the forefront of industry advancements.

Key Performance Metrics for Evaluating Chemical Metering Technologies

When evaluating chemical metering technologies, key performance metrics play a crucial role in ensuring precision and efficiency in industrial applications. Critical metrics include flow accuracy, response time, and durability. According to a recent industry report by Research and Markets, accurate flow measurement can reduce chemical waste by up to 25%, significantly lowering operational costs. Additionally, rapid response times—typically measured in milliseconds—are essential for processes requiring immediate adjustments, such as in wastewater treatment where chemical dosing needs can fluctuate dramatically.

To enhance the effectiveness of chemical metering solutions, consider these tips: First, always perform regular calibration to maintain precision over time. A well-calibrated meter can improve accuracy by up to 15%, as noted in the latest technical guidelines from the American Society of Mechanical Engineers. Second, seek out metering technologies that integrate real-time monitoring features. These can provide invaluable insights into system performance, helping identify potential issues before they escalate. Finally, investing in durable materials and design can significantly extend the lifespan of metering equipment, reducing replacement costs and ensuring a consistent metering flow even in harsh environments.

Emerging Technologies in Chemical Metering: Focus on Smart Sensors and IoT

Emerging technologies are revolutionizing the field of chemical metering, particularly through the integration of smart sensors and IoT solutions. These advancements are driving precision and efficiency in sectors such as water treatment and agricultural applications. For instance, the global sensor market is projected to reach a staggering USD 250 billion by 2036, fueled by technological advancements in AI, robotics, and connectivity. This remarkable growth underscores the critical role that smart sensors play in optimizing chemical metering processes.

Furthermore, the rise of AI-powered operational intelligence is enabling more effective management of chemical distributions in real-time, thus enhancing sustainability measures. The Narrowband Internet of Things (IoT) chipset market is also seeing significant growth, with an expected CAGR of 57.80%, reaching an estimated USD 114.88 billion by 2034. This surge is indicative of the increasing reliance on interconnected devices to monitor chemical applications, improve accuracy, and reduce waste, ultimately contributing to more sustainable practices within industries. As these technologies continue to evolve, they promise to reshape the metering landscape and facilitate smarter resource management in the years to come.

2025 Top 5 Chemical Metering Solutions for Precision and Efficiency

This chart illustrates the projected market share of the top five chemical metering solutions in 2025, highlighting their efficiency and precision in chemical management.

Impact of Automation on Chemical Metering Accuracy and Efficiency in Manufacturing

The automation of chemical metering has significantly transformed manufacturing processes, enhancing both accuracy and efficiency. With the integration of advanced technology, manufacturers are now able to achieve precise measurements, reducing the risk of human error and ensuring consistent quality in production. Automated systems utilize sophisticated sensors and control mechanisms that continuously monitor and adjust chemical flow rates, enabling optimal performance and minimal waste.

**Tips:** When considering automation for chemical metering, ensure that you select systems that offer real-time data analytics. This capability allows for immediate adjustments to be made, thus maintaining precision in chemical dosing. Additionally, look for solutions that are easy to integrate with existing manufacturing setups, minimizing downtime during installation.

Moreover, automation offers the potential for predictive maintenance, where data collected from metering systems can forecast potential issues before they lead to failure. This proactive approach not only enhances operational efficiency but also extends the life of the equipment. Implementing automated chemical metering not only drives productivity but also positions businesses to better adapt to future manufacturing challenges.

**Tips:** Regularly train staff on the new technologies being implemented. This ensures that employees are well-versed in troubleshooting and maintaining these automated systems, which is crucial for sustained efficiency and effectiveness in the long run.

Cost-Benefit Analysis of the Leading Chemical Metering Solutions in 2025

In 2025, the landscape of chemical metering solutions is defined by advancements in precision and efficiency. The leading solutions not only enhance operational performance but also deliver significant cost savings over time. A thorough cost-benefit analysis reveals that these metering systems, while initially requiring a hefty investment, rapidly pay off through reduced chemical waste, improved accuracy in formulations, and enhanced productivity. Companies can expect to see a return on investment within a few years as these systems minimize errors and maximize resource utilization.

Comparing the top five chemical metering solutions, various factors, such as maintenance costs, reliability, and ease of integration into existing processes, are critical in assessing their overall value. Solutions that incorporate smart technology, like IoT capabilities for real-time monitoring and adaptive control, provide additional long-term cost benefits. Additionally, organizations will find that the ability to scale their operations without significant reinvestment in equipment will further enhance the economic viability of these leading products, making them essential tools in the modern chemical industry.

Related Posts

-

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

7 Essential Tips for Choosing the Right Chemical Injection Pumps

-

What is a Chemical Pump? Understanding Types, Uses, and Benefits for Your Industry

-

Ultimate Guide to Choosing the Right Chemical Mixer: Key Features and Industry Insights

-

2025 Guide to Choosing the Best Chemical Injection Pumps for Your Needs