Blog

2025 Top 10 Chemical Metering Pumps for Precision Fluid Control

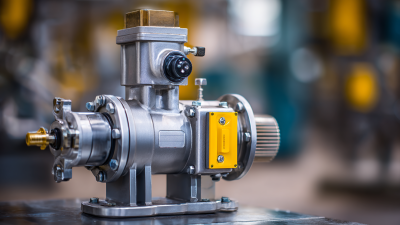

In the intricate world of fluid management, precision is paramount. The use of chemical metering pumps has become increasingly vital for industries that require accurate and consistent fluid control. As noted by Dr. Emily Harrington, a leading expert in fluid dynamics, "The reliability of a chemical metering pump can drastically influence the efficiency and safety of chemical processes." This statement encapsulates the importance of selecting the right pump, especially as we approach 2025, a year projected to bring advancements in pump technology.

In this article, we will explore the top 10 chemical metering pumps that stand out for their precision, efficiency, and adaptability to various applications. With a focus on the latest digital technologies and innovations in the industry, these pumps are designed to meet the demanding needs of modern manufacturing and treatment processes. As industries evolve, so too must the tools they employ, making understanding the capabilities and features of each pump essential for optimizing performance and ensuring operational sustainability.

Join us as we delve into the details of these 2025 top contenders in the chemical metering pump market, providing insights that will help you make informed decisions for your fluid control needs.

Overview of Chemical Metering Pump Types for Precision Applications

Chemical metering pumps play a crucial role in precision fluid control across various industries. They are designed to deliver exact volumes of fluids under controlled conditions, making them essential for applications that require high levels of accuracy and reliability. The primary types of chemical metering pumps include peristaltic pumps, diaphragm pumps, and screw pumps, each serving unique operational needs. For instance, peristaltic pumps are favored for their ability to handle a wide range of fluids while ensuring contamination-free transfer, which is pivotal in pharmaceutical and food processing industries.

The burgeoning demand for precise fluid management is driving the growth of the dosing pumps market, which has exceeded USD 7.8 billion as of 2024, with projections indicating a robust CAGR of 6.9% through 2034. Innovations in this sector, particularly those aimed at enhancing automation and promoting eco-friendly practices, are helping industries meet their sustainability goals. As organizations increasingly prioritize efficiency and environmental responsibility, advancements in chemical metering technologies are set to revolutionize fluid dispensing capabilities, ensuring they meet both operational demands and regulatory standards.

Key Features and Benefits of Each Metering Pump Type

In the evolving landscape of precision fluid control, the metering pumps market is anticipated to grow significantly, projected to reach USD 9.1 billion by 2030. This growth is attributed to the increasing demand across various industries, particularly in water treatment and healthcare sectors. Metering pumps are essential in delivering accurate fluid flow rates, and their various types, such as diaphragm, peristaltic, and rotary gear pumps, each offer distinct advantages. For instance, diaphragm pumps are celebrated for their reliability and chemical resistance, making them ideal for harsh environments, while peristaltic pumps are known for their gentle handling of fluids, crucial in pharmaceutical applications.

Furthermore, advancements in technology have led to a wave of innovation within the metering pump sector. Smart metering solutions integrated with machine learning frameworks are optimizing efficiency and enhancing performance metrics. The expected CAGR of 4.1% in this market reflects a robust trend toward more sophisticated and user-friendly systems. As businesses adapt to evolving technical challenges, understanding the key features and benefits of each metering pump type will be vital for maintaining a competitive edge in fluid management processes.

2025 Top 10 Chemical Metering Pumps for Precision Fluid Control

| Pump Type | Flow Rate Range | Pressure Range | Material Compatibility | Key Features | Benefits |

|---|---|---|---|---|---|

| Diaphragm Pump | 0.5 - 50 L/h | 0 - 10 bar | Acids, Bases | Self-priming, Leak-free | High accuracy, Low maintenance |

| Gear Pump | 1 - 100 L/h | 0 - 20 bar | Hydrocarbons, Oils | High viscosity handling | Consistent flow, Robust design |

| Peristaltic Pump | 0.1 - 1000 L/h | 0 - 4 bar | Chemicals, Slurries | Gentle pumping action, Easy maintenance | Minimal pulsation, Versatile |

| Rotary Lobe Pump | 5 - 1000 L/h | 0 - 7 bar | Viscous Fluids | Non-contact design, Variable speed | High shear sensitivity, Easy cleaning |

| Sinusoidal Pump | 0.5 - 300 L/h | 0 - 5 bar | Chemicals, Food products | Low shear, hard to pump media | Gentle pumping, Reduced frothing |

| Diaphragm Metering Pump | 0.1 - 50 L/h | 0 - 16 bar | Abrasive fluids | Variable stroke length | High repeatability, Versatile |

| Plunger Pump | 1 - 200 L/h | 0 - 30 bar | Solvents, Clean fluids | High pressure operation | Durable, Efficient |

| Nutrient Dosing Pump | 10 - 500 L/h | 0 - 5 bar | Liquids, Nutrients | Precise dosage control | Enhanced growth rates, Eco-friendly |

| Electric Metering Pump | 5 - 250 L/h | 0 - 6 bar | Water, Mild Chemicals | Digital control, Programmable | User-friendly, High precision |

| Magnetic Drive Pump | 1 - 100 L/h | 0 - 8 bar | Corrosive liquids | Sealless design | Safety, Reliability |

Comparative Analysis of the Top 10 Chemical Metering Pumps in 2025

The metering pumps market, estimated to reach USD 7.5 billion by 2025, is witnessing a surge driven by the increasing demand for precise fluid control across various industries. A comparative analysis of the top ten chemical metering pumps reveals significant advancements in technology, efficiency, and application versatility. These pumps play a crucial role in sectors such as water treatment, chemical processing, and pharmaceuticals, where accuracy and reliability are paramount.

In evaluating these leading metering pumps, experts emphasize the importance of parameters including flow rate, pressure range, and compatibility with various chemicals. Moreover, innovations in smart technology integration, such as automated controls and real-time monitoring capabilities, are enhancing operational efficiency. As a result, industries are increasingly prioritizing pumps that not only meet their specific operational requirements but also offer long-term durability and lower maintenance costs. This landscape is shaping the future of fluid control solutions, positioning top products as essential tools driving productivity and sustainability in manufacturing processes.

2025 Top 10 Chemical Metering Pumps for Precision Fluid Control

Common Applications for Chemical Metering Pumps in Industry

Chemical metering pumps play a crucial role in various industries where

precision fluid control is essential. One of

the most common applications for these pumps is in the water treatment sector, where they are

employed to add chemicals such as chlorine and coagulants to ensure

safe and clean water. The ability of metering pumps

to deliver exact volumes at controlled rates makes them indispensable for maintaining water quality standards

and protecting public health.

Another significant application is seen in the pharmaceutical industry, where

precise dosing of drug compounds is vital for product safety and

effectiveness. Chemical metering pumps are used to facilitate the accurate addition of active ingredients

during production processes. This precision not only minimizes waste but also ensures compliance with

stringent regulatory requirements, ensuring that dosages

remain consistent from batch to batch. Additionally, metering pumps are utilized in agriculture for the

efficient application of fertilizers and pesticides,

enabling more effective crop management while reducing environmental impacts.

Future Trends in Chemical Metering Pump Technology and Design

The future of chemical metering pump technology is poised for significant advancements, driven by increasing demands for precision in fluid control across various industries. Emerging trends indicate a movement towards enhanced automation and smart technology integration, enabling real-time monitoring and adjustment of fluid delivery systems. This evolution is crucial for industries such as pharmaceuticals, chemicals, and water treatment, where accuracy can dramatically impact operational efficiency and product quality.

Moreover, the market for hydraulic dosing pumps is forecasted to reach $4.5 billion by 2035, reflecting a compound annual growth rate (CAGR) of 4.0% between 2025 and 2035. Alongside this, the chemical injection pumps market is anticipated to achieve a staggering revenue of $96 billion by 2033, growing at a CAGR of 8.4%. This growth trajectory signals not only an increase in demand for higher performance and reliability in pump technology but also the necessity for manufacturers to innovate and adapt in order to meet the evolving needs of their clients.

Related Posts

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

How to Choose the Right Chemical Metering Pump for Your Industry Needs

-

10 Unique Metering Pump Types You Should Know About