Blog

Essential Tips for Choosing a Chemical Metering Pump System?

Choosing the right chemical metering pump system is crucial for many industrial applications. According to Dr. Alice Thornton, an expert in fluid dynamics, "The efficiency of your system heavily relies on the selection of the right pump." Her insight highlights the importance of making informed choices in this area.

When evaluating options, consider factors like flow rate and chemical compatibility. Each application may have unique requirements. A pump that works well for one process might fail in another. Small details, like material composition, can make a significant difference.

Many professionals overlook the importance of maintenance. A poorly maintained chemical metering pump system can lead to costly downtime and safety issues. Reflecting on past decisions can help in making better choices now. In the end, understanding your specific needs is vital in selecting an effective system.

Understanding the Basics of Chemical Metering Pump Systems

Chemical metering pump systems play a vital role in various industries. They ensure precise dosing of chemicals. Applications include water treatment, agriculture, and food processing. According to a recent report by MarketsandMarkets, the global chemical metering pump market is expected to grow to approximately $4 billion by 2025. This growth underscores the importance of choosing the right system.

Understanding the basics is crucial. There are different types of pumps, such as diaphragm and peristaltic. Each type has its advantages and limitations. Diaphragm pumps offer high accuracy but can be prone to leaks. Peristaltic pumps may have lower accuracy but are easy to maintain. Identifying the right type depends on your specific needs and operational conditions.

Consider the pump's flow rate and pressure requirements. Poorly matched pumps can lead to performance issues. Some users overlook the importance of compatibility with the chemicals being pumped. Incorrect compatibility can result in equipment failure and added costs. Regular maintenance is often neglected, leading to system inefficiencies. It's a reminder that understanding your pump system is key to achieving reliable operation.

Key Factors to Consider When Selecting a Metering Pump

When selecting a metering pump, several key factors come into play. The flow rate is crucial. It should match your application's needs. Too high or too low a flow can disrupt the process. Additionally, consider the fluid's properties. Viscosity, temperature, and chemical compatibility are vital in determining the right pump type. For example, corrosive fluids may require special materials. These specifics often get overlooked.

Another aspect to think about is installation space. Ensure the pump fits comfortably. An awkward fit can lead to maintenance issues down the line. Also, think about power requirements. Some pumps need specific voltages. This can complicate installation if not planned properly.

Lastly, don't forget about maintenance. Regular upkeep can extend the pump's lifespan. However, some systems are easier to maintain than others. This aspect can be a game changer for operational efficiency. It's beneficial to reflect on how user-friendly the system will be. Cost and performance should be balanced carefully. Cheaper options may fall short on reliability. So, weigh all considerations before making a decision.

Essential Tips for Choosing a Chemical Metering Pump System

| Key Factor | Description | Importance Level |

|---|---|---|

| Flow Rate | The required flow rate indicates the volume of fluid that needs to be delivered per unit time, crucial for process efficiency. | High |

| Viscosity of Fluid | Understanding fluid viscosity is essential for selecting a pump that can handle the specific characteristics of the chemical being pumped. | Medium |

| Chemical Compatibility | Selecting materials that are compatible with the chemicals being pumped prevents material degradation and ensures safety. | High |

| Pressure Requirements | Knowing the operational pressure helps in selecting a pump that can effectively handle the system’s demands. | High |

| Power Supply | Understanding the availability of power supply (AC, DC) is vital to ensure proper pump operation and integration. | Medium |

| Accuracy | The precision of the pump in delivering the required amount of chemical is critical for achieving the desired process outcomes. | High |

| Maintenance Requirements | Consider the maintenance needs of the pump system to ensure longevity and reliability over time. | Medium |

Types of Chemical Metering Pumps and Their Applications

Choosing the right chemical metering pump system is crucial for various industrial applications. There are several types of pumps available, each designed for specific purposes. Positive displacement pumps are common. They provide precise flow rates and are ideal for high-viscosity fluids. According to industry data, these pumps can handle pressures up to 3,000 psi, suitable for rigorous environments.

Diaphragm pumps are another type. They’re valuable for corrosive or hazardous chemicals. These pumps reduce the risk of leaks, but they may require frequent maintenance. End users often find that diaphragm pumps can improve safety but at a cost of higher complexity in setup.

When selecting a pump, consider the application and fluid properties. Tips include analyzing the viscosity and chemical compatibility of the fluids. Always review the operational pressure and desired flow rate. Misjudging these factors could lead to pump failure. It’s also wise to think about the pump's energy efficiency. Investing in quality can pay off in the long run. Reflecting on these choices can enhance operational productivity.

Evaluating Pump Performance and Efficiency Metrics

When considering a chemical metering pump system, pump performance is crucial. Efficiency metrics include flow rate, pressure, and accuracy. A higher flow rate may seem ideal. However, it might lead to over-consumption of chemicals. This can be costly and wasteful. Always assess whether the pump can handle required pressure levels. Look at the specific application needs.

Accuracy is just as important. A pump that delivers an exact amount of chemicals may reduce errors. Inconsistent chemical delivery can lead to product quality issues. Evaluate the pump's calibration process. Can it be easily adjusted? This is vital when dealing with varying production demands.

Don't overlook maintenance aspects. A highly efficient pump may still require frequent servicing. This can negate its overall efficiency. Choose a system that balances performance, ease of maintenance, and cost. Reflect on your actual needs. Consider the long-term implications of your choice. Such a thoughtful approach can promote more sustainable practices in the long run.

Maintenance and Support for Chemical Metering Pump Systems

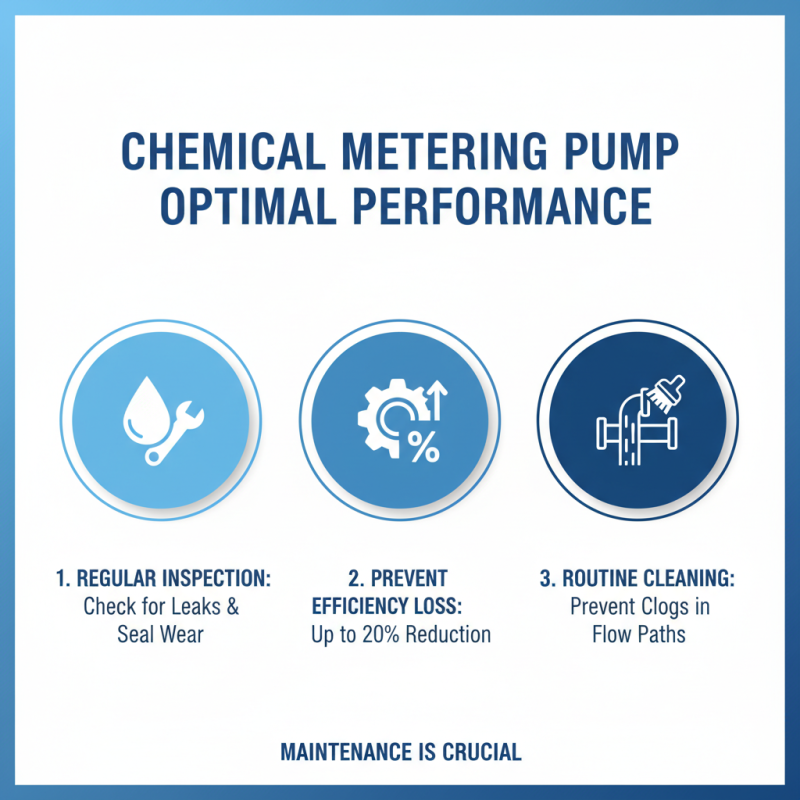

Maintaining a chemical metering pump system is crucial for optimal performance. Regular inspection is essential. Users should check for leaks and wear on seals frequently. In fact, data shows that improper maintenance can reduce efficiency by over 20%. This makes routine care indispensable. Regular cleaning can prevent solids from clogging the flow paths.

Support is also vital for these systems. Staff should be trained on troubleshooting basics. Reports indicate that 30% of system failures could be avoided with proper training. Having a maintenance schedule is a good practice. Scheduling activities, like replacing parts every six months, ensures longevity.

Feedback from technicians often reveals that many systems operate under hidden issues. Electrical connections may degrade over time. It is useful to keep a log of maintenance actions and concerns for future reference. Regular assessments ensure you are not left with an unexpected breakdown. Adopting a proactive approach is key.

Related Posts

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

2025 Top Chemical Metering Pump System Insights and Innovations

-

2025 Top 10 Chemical Metering Pumps for Precision Fluid Control

-

Understanding the Role of Chemical Metering Pumps in Sustainable Industry Practices

-

What is an Industrial Pump? Understanding Types, Uses, and Benefits

-

2025 Top Chemical Metering Pump Innovations and Best Practices