Blog

Essential Tips for Choosing a Chemical Metering Pump?

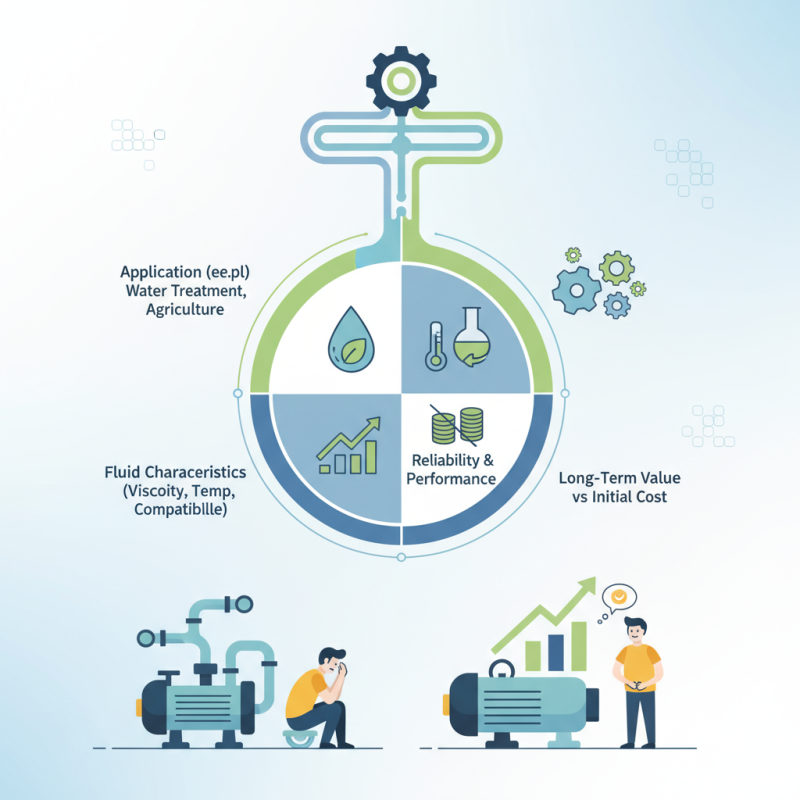

When selecting a chemical metering pump, key factors come into play. The right pump ensures efficient dosing. This choice can impact operations significantly.

Consider the application when choosing a chemical metering pump. Different industries have unique requirements. For example, water treatment and agriculture need specific features. Assessing fluid characteristics is crucial. Viscosity, temperature, and chemical compatibility matter greatly.

It’s easy to overlook these details. A poorly chosen pump may lead to inefficiencies. Reflect on the long-term implications of your selection. Prioritize reliability and performance in your decision-making. Your choice should reflect practical needs, not just initial costs. Explore options thoroughly before making a commitment.

Understanding the Basics of Chemical Metering Pumps

Chemical metering pumps are essential in various industries. They accurately dispense a precise volume of chemicals. Understanding their basics is crucial for effective application. These pumps can handle different types of fluids. Choosing the right one can significantly impact efficiency.

When selecting a chemical metering pump, consider flow rate first. It is vital to determine the required volume per hour. This ensures the pump meets the system's demands. Different applications may require different flow rates. Measure carefully to avoid under or over-pumping.

Also, look into the pump materials. They must be compatible with the chemicals being pumped. Some materials may degrade over time. This can lead to leaks or pump failure. Check the chemical properties to avoid costly mistakes. Keep in mind that not all pumps are foolproof. Understanding your specific needs will help you choose wisely.

Key Features to Consider When Selecting a Pump

When selecting a chemical metering pump, specific features are crucial. One of the key aspects to consider is the pump's flow rate. Industry reports suggest that 70% of applications require precise flow control. A pump's capacity should match the specific needs of your system. Overestimating flow can lead to waste; underestimating can cause insufficient dosing.

Another critical feature is the materials of construction. Pumps must withstand corrosive chemicals. Reports highlight that using the wrong material can lead to pump failure. For instance, stainless steel pumps are ideal for many applications, but certain environments may need more resistant materials. It's vital to reflect on the environmental conditions before making a choice.

Lastly, consider the pump's ease of maintenance. The complexity of maintenance can impact operational efficiency. Many users discover that less accessible pumps create challenges. A design that allows for easy inspection and servicing is worth prioritizing. It reduces downtime and helps maintain consistent performance.

Essential Tips for Choosing a Chemical Metering Pump

| Feature | Importance | Considerations |

|---|---|---|

| Flow Rate | Critical for application needs | Match with process requirements |

| Pressure Rating | Ensures pump durability | Check system pressure specifications |

| Pump Type | Impacts efficiency and maintenance | Select between diaphragm, peristaltic, etc. |

| Material Compatibility | Prevents leakage and damage | Assess chemical properties of fluids |

| Control Options | Enhances precision and automation | Evaluate manual vs digital controls |

| Maintenance Requirements | Affects downtime and costs | Research service intervals and ease of access |

Evaluating Pump Types for Specific Applications

When evaluating pump types for specific applications, consider the liquid's characteristics. Viscosity plays a crucial role. For thicker liquids, a diaphragm pump may be necessary. These pumps excel in handling viscous substances. On the other hand, peristaltic pumps are ideal for shear-sensitive liquids. They minimize contact, ensuring gentle handling.

Next, think about the pressure requirements. Some applications need high pressure, while others do not. For instance, a high-pressure plunger pump can deliver consistent flow rates at high pressures. Conversely, gear pumps are suitable for lower-pressure applications. They provide stable flow without excessive turbulence.

Finally, account for the environment where the pump will operate. Corrosive substances require special materials. It’s not always easy to find the right fit. Not all pumps can withstand harsh environments. Choosing the wrong type could lead to failures. Reflect on these factors carefully, for the right metering pump can significantly impact your operations.

Assessing Material Compatibility and Durability Factors

Selecting the right chemical metering pump involves examining material compatibility and durability. This process can be complex. Different chemicals interact uniquely with various materials. For instance, acids can corrode metals rapidly, while certain plastics may degrade. Knowing the chemical you’ll work with is essential. Always check compatibility charts before making a choice.

Durability is another critical factor. Pumps often face harsh conditions, such as temperature fluctuations and exposure to chemicals. Using pumps made from high-grade materials can extend their lifespan. Look for options that resist wear and can withstand pressure. However, sometimes manufacturers overlook the subtle interactions between materials and chemicals. It’s important to ask questions and seek advice.

The environment in which the pump will operate also matters. Factors like humidity, temperature, and presence of other chemicals can impact performance. For example, a pump might fail prematurely if exposed to moisture. Regular maintenance can help identify potential issues early. Reflect on your operational needs and choose a pump that can adapt and endure.

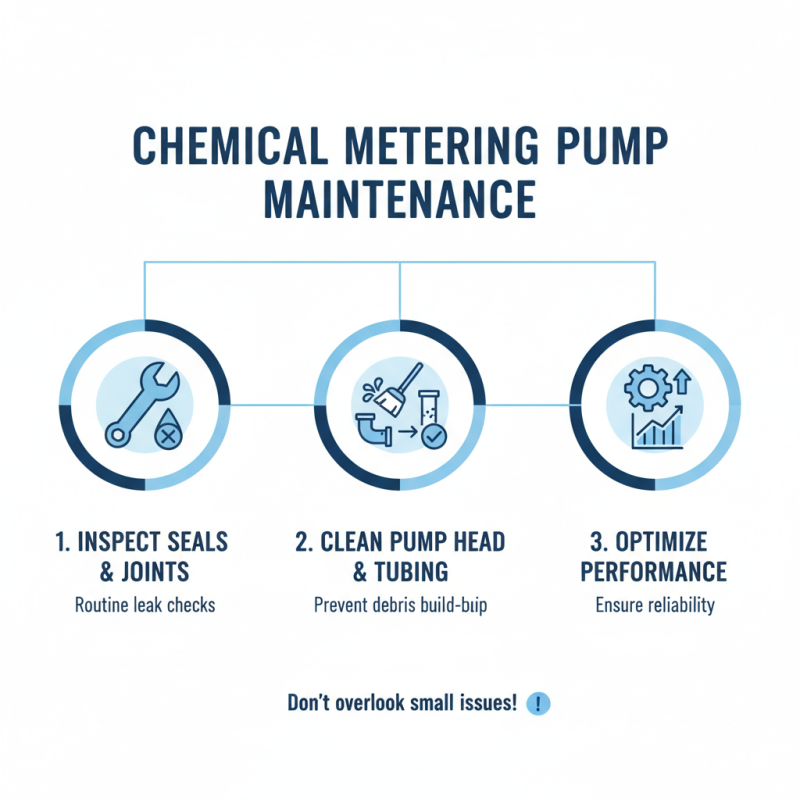

Maintenance and Support Options for Chemical Metering Pumps

When considering maintenance for chemical metering pumps, routine checks are vital. Inspect seals and joints regularly. Small leaks can lead to significant issues. Clean the pump head and tubing to prevent build-up. It's often overlooked, yet debris can affect performance.

Support options come in many forms. Some manufacturers offer extensive online resources. Access to troubleshooting guides and FAQs can be helpful. Consider training for staff members. Though not always feasible, trained personnel can prevent mistakes. Not everyone learns the same way. In-person training sessions might be more effective for some teams.

Service contracts may seem daunting. Yet, they can save costs long-term. Regular service means fewer breakdowns. A pump that stops working can halt production, leading to lost time and money. While service contracts require investment, they often pay off. Assessing options might reveal better choices for your specific needs.

Related Posts

-

Understanding the Role of Chemical Metering Pumps in Sustainable Industry Practices

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency

-

Understanding the Role of Industrial Metering Pumps in Modern Manufacturing Processes

-

2025 Top Metering Pump Innovations for Precision Fluid Control