Blog

Best Suction Pump Types for Every Application Guide?

Suction pumps play a vital role in various industries, from agriculture to healthcare. The global suction pump market is projected to reach $5.6 billion by 2027, according to a recent report by Market Research Future. This underscores the importance of understanding different suction pump types. They are critical in processes like fluid transfer, waste removal, and even medical applications.

Different applications require specific suction pump designs. For example, oil and gas industries favor diaphragm pumps. Medical applications, on the other hand, often use portable suction pumps for patient care. However, users often overlook the significance of selecting the right type. The wrong choice can lead to inefficiencies or equipment failure.

Choosing the best suction pump is no small task. Factors like viscosity, flow rate, and the type of fluid matter. Each application presents unique challenges. Understanding these elements is essential for optimal performance. In an industry that cannot afford downtime, making informed choices is crucial.

Understanding the Basics of Suction Pumps and Their Functionality

Suction pumps serve vital roles in various industries. They create a vacuum that draws fluids or gases. Understanding their functionality is key to selecting the right type for different applications. Most pumps operate through a simple mechanism: when the pump lowers pressure, it causes the fluid to flow in. This process seems straightforward but can lead to inefficiencies. Small design flaws can drastically reduce performance.

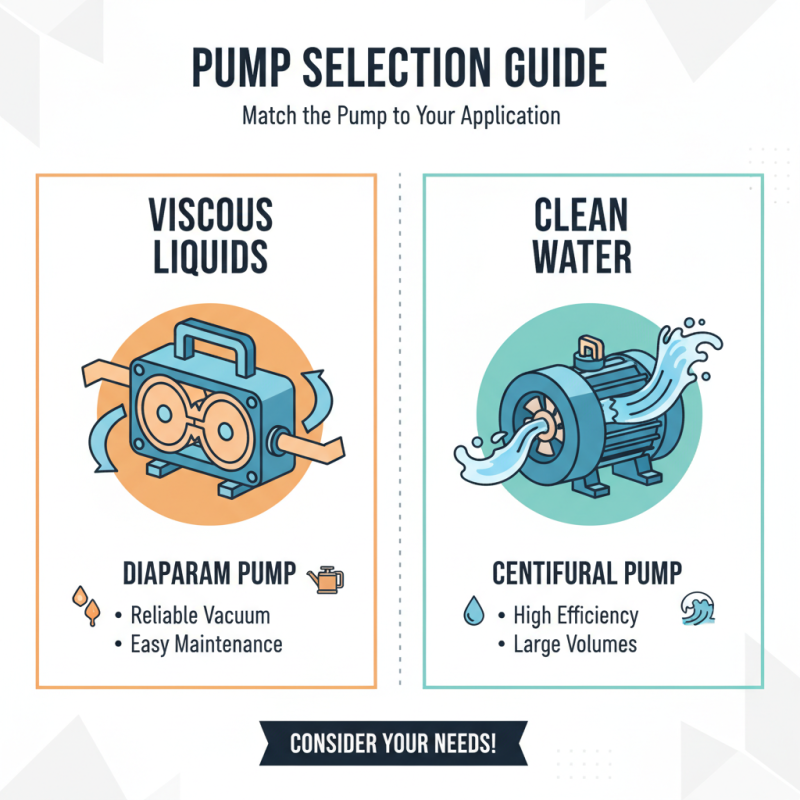

There are various types of suction pumps, each suited for specific tasks. For instance, diaphragm pumps are excellent for transferring thick liquids. However, they may struggle with fine particles. On the other hand, centrifugal pumps efficiently move clear fluids but can be less effective with viscous substances. It's important to reflect on the application’s unique demands when choosing the pump type. Making assumptions without proper analysis can result in costly mistakes.

In practice, selecting the right suction pump often feels overwhelming. Factors like viscosity, temperature, and chemical compatibility must be considered. It's easy to overlook these details. A well-made choice can save time and resources, while an incorrect one can lead to operational headaches. Therefore, a thoughtful approach is essential.

Types of Suction Pumps: An Overview of Varieties and Uses

Suction pumps come in various types, each designed for specific applications. Positive displacement pumps are among the most common. They move fluids by trapping a fixed amount and forcing it into the discharge pipe. These pumps are ideal for thick fluids. They handle slurries and viscous liquids well.

Another popular type is the centrifugal pump. This pump uses rotational energy to move fluids. It works best for thin liquids and is widely used in water treatment. However, these pumps are less efficient with thick fluids. The design may lead to cavitation if not managed.

Diaphragm pumps are also noteworthy. They are useful for applications requiring sanitation. They prevent backflow and contamination. These pumps have a simpler design but may need regular maintenance. Choosing the right pump can be challenging. Each type has its strengths and weaknesses. Understanding the specific application can help make the right choice.

Choosing the Right Suction Pump for Specific Applications

When choosing a suction pump, consider the application carefully. Different pumps serve unique purposes. For instance, diaphragm pumps are ideal for transferring viscous liquids. They provide a reliable vacuum and are easy to maintain. If you're dealing with clean water, a centrifugal pump might be your best option. It's efficient and can handle large volumes quickly.

Think about the environment where the pump will operate. Some pumps work better in harsh conditions than others. For example, a gear pump can handle high-pressure tasks with ease. However, it might not be suitable for delicate fluids. Each option has its pros and cons.

Reflecting on pump selection often reveals overlooked details. The size of the pump matters significantly. It needs to fit the available space and meet capacity requirements. Overestimating or underestimating can lead to performance issues. Always balance functionality with practicality. Choosing the right suction pump requires careful thought and awareness of specifics.

Comparative Analysis of Electric vs. Manual Suction Pumps

When choosing between electric and manual suction pumps, several factors come into play. Electric models are often praised for their efficiency. According to industry data, electric pumps can operate at a rate of 1-2 liters per minute, allowing for rapid extraction. This can be critical in medical settings where time is of the essence. However, the reliance on electricity may pose limitations in remote areas or during power outages.

Manual suction pumps, on the other hand, offer a different set of advantages. Typically lighter and more portable, they require no external power supply. In emergencies, a manual pump can save valuable time. Industry reports indicate that they can effectively serve in situations where reliability matters most. Still, using them effectively requires more physical effort and may lead to user fatigue. This can affect performance during prolonged use, raising questions about their practicality in all scenarios.

Both pump types bring unique challenges. While electric pumps may seem more advanced, manual options offer durability and independence. Evaluating specific needs can guide the decision-making process, but a balance between efficiency and practicality is essential. The right choice ultimately depends on the application and circumstances.

Maintenance Tips for Prolonging the Life of Your Suction Pump

Proper maintenance is critical for extending the lifespan of any suction pump. Regular maintenance can enhance performance and prevent costly breakdowns. According to recent industry reports, implementing a routine inspection schedule can increase a pump's efficiency by up to 30%. Checking for leaks is vital. Even minor leaks can lead to significant performance issues. Ensure that seals and connections are intact and functioning.

Cleaning the suction filters regularly can also prolong pump life. Clogged filters can diminish suction capability. This can lead to overheating and eventual damage. It's recommended to clean or replace filters at least every three months. Also, ensure that the pump is operated within its specified parameters. Exceeding pressure limits can cause wear and tear on internal components.

Lubrication is another overlooked aspect of pump maintenance. Using the correct lubricants reduces friction and heat. This prevents premature failure. Regularly checking lubricant levels helps avoid unnecessary damage. However, over-lubrication can lead to other issues as well. Finding that balance can be tricky, and it's often ignored. Each type of pump has specific requirements, so detailed knowledge is essential.

Related Posts

-

10 Essential Tips for Choosing the Right Suction Pump for Your Needs?

-

The Future of Suction Pump Technology Revolutionizing Efficiency and Performance

-

How to Use a 3 Pump System for Optimal Performance?

-

2025 Top Metering Pump Innovations for Precision Fluid Control

-

Understanding the Benefits of Chemical Metering Pumps in Modern Water Treatment Systems

-

Understanding the Importance of Chemical Pumps in Modern Industrial Processes