Blog

How to Choose the Right Metering Pump Types for Your Applications?

Choosing the right metering pump types is crucial for efficient operations in various industries. In 2022, the global metering pumps market was valued at over $4 billion, and it is expected to grow. This growth underscores the need for selecting the most suitable pump types for specific applications. Different sectors include water treatment, chemical processing, and food and beverage. Each of these has unique requirements.

Metering pump types vary significantly in design and functionality. For example, diaphragm pumps provide accurate flow rates ideal for chemical dosing. On the other hand, peristaltic pumps excel in hygienic applications. However, it can be daunting to determine which type best fits your needs. Many operators overlook crucial factors like viscosity, temperature, and pressure tolerance when making their choice.

In the quest for precision, it is essential to analyze not just cost but also operational efficiency. Poor choices can lead to costly downtime or product quality issues. Reflecting on past decisions can offer valuable insights, highlighting the importance of thorough research and evaluation. Understanding the specific demands of your application will guide you in making better-informed selections.

Understanding Different Types of Metering Pumps and Their Applications

Choosing the right metering pump for your application can be challenging. There are various types available, each suited for different tasks. For instance, diaphragm pumps are excellent for precise dosing, while gear pumps handle high-viscosity fluids well. This variation means that understanding your specific needs is crucial.

Applications vary significantly. Chemical processing, for example, often requires pumps that can manage corrosive substances. In contrast, water treatment might focus on pumps that ensure accurate flow rates. Consider environmental factors, such as temperature and pressure, too. Some pumps perform poorly outside their specified conditions. Assessing these variables is essential but can be complex.

Not all pumps are created equal. Sometimes, a budget-friendly option might be the wrong choice for your needs. Reliability often comes with a higher price tag. However, it’s easy to overlook this when focusing only on upfront costs. You may be tempted to prioritize speed over precision, but this can lead to costly errors. Be critical of your choices. Reflection on your application and needs can lead to better outcomes.

How to Choose the Right Metering Pump Types for Your Applications?

| Pump Type | Application | Flow Rate Range (L/h) | Pressure Range (bar) | Fluid Compatibility |

|---|---|---|---|---|

| Diaphragm Pump | Chemical Processing | 0.1 - 1000 | 0 - 15 | Acids, Bases |

| Gear Pump | Food Processing | 1 - 500 | 0 - 20 | Viscous Liquids |

| Peristaltic Pump | Water Treatment | 0.01 - 300 | 0 - 3 | Slurries, Flocculants |

| Screw Pump | Oil and Gas | 5 - 800 | 0 - 30 | Heavy Oils, Chemicals |

| Solenoid Pump | Laboratory Settings | 0.01 - 100 | 0 - 1.5 | Water, Mild Acids |

Key Factors to Consider When Selecting a Metering Pump

When selecting a metering pump, several key factors come into play. Understanding the flow rate is essential. You need to know how much liquid you want to move, measured in gallons per hour or liters per minute. This will influence your pump choice significantly. Consider the fluid’s viscosity, too. Thicker fluids require different pumps compared to water-like substances.

Sizes and materials matter as well. Pumps come in various sizes, which can affect installation. Materials used will impact the pump's resistance to corrosion and wear. In some cases, materials might not be suitable for certain chemicals. This can reflect long-term costs when maintenance rises.

Tip: Always analyze the compatibility of pump materials with your fluid.

Another factor is pressure requirement. Each application has a unique pressure need. Pumps should handle those pressures without damage.

Tip: Test your selected pump under real conditions to see how it performs.

Consider the operational environment, too. Is it clean or abrasive? Will the pump be exposed to temperature extremes? These variables influence pump longevity and performance. The right choice can save maintenance costs and downtime in the long run.

Comparing Positive Displacement and Air-Operated Diaphragm Pumps

When selecting a metering pump, understanding the differences between positive displacement and air-operated diaphragm pumps is crucial. Positive displacement pumps are efficient. They are known for their precise flow rates. These pumps operate by trapping a fixed volume and forcing it through the discharge. They are ideal for viscous and high-pressure applications. However, their complexity can lead to maintenance challenges.

On the other hand, air-operated diaphragm pumps are versatile and simple. They use compressed air to move the diaphragm, which creates flow. This type is suitable for a variety of fluids, including shear-sensitive liquids. They tend to be easier to maintain, but they may not deliver the same precision as positive displacement pumps. Air-operated pumps can be less efficient in certain scenarios.

When choosing a pump, consider your specific application needs. Think about the fluid characteristics and required flow rates. Reflect on the long-term maintenance and operational costs. Each pump type has its strengths and weaknesses. It’s essential to weigh these aspects carefully. Making the right choice can lead to improved processes and reduced downtime.

Evaluating Flow Rate, Pressure, and Chemical Compatibility

When selecting the right metering pump, flow rate, pressure, and chemical compatibility play crucial roles. Flow rate is often defined in gallons per minute (GPM) or liters per hour (LPH). Many applications require precise flow rates, sometimes within 0.5% accuracy. For instance, a report by the International Society for Measurement and Control suggests that a deviation as small as 1% can lead to significant errors in chemical dosing, impacting overall process efficiency.

Pressure rating is another critical factor. Typically, metering pumps operate under pressures ranging from 5 to 500 psi. In some industries, even higher pressures are needed. In a chemical processing environment, a pump that can't handle the required pressure could fail, resulting in costly downtime. Reports indicate that 30% of unscheduled maintenance in manufacturing stems from inadequate pump performance under pressure.

Chemical compatibility is vital. Different materials resist corrosion differently. For example, PVC may work in mild applications, but not in strong acids. It’s essential to verify compatibility with specific fluids. Failing to do so could lead to pump failure or environmental hazards. Data shows that more than 20% of pump failures could be traced back to material incompatibility. Thus, a thorough evaluation of these factors is necessary, aiming for a well-informed decision.

Best Practices for Metering Pump Installation and Maintenance

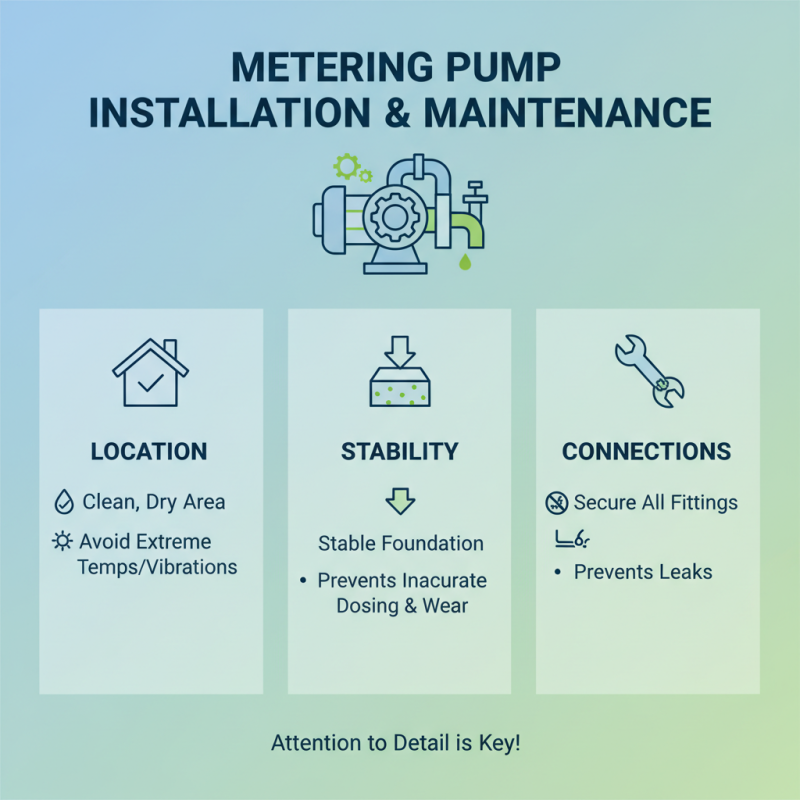

Installing and maintaining metering pumps demands attention to detail. Start by ensuring the pump is placed in a clean, dry area. Avoid locations with extreme temperatures or vibrations. Check that the foundation is stable. An unstable base can lead to inaccurate dosing and premature wear. Remember to secure all fittings tightly to prevent leaks.

During maintenance, routine checks are crucial. Inspect the seals and check for any wear or damage. A worn seal can cause leaks and reduce efficiency. Cleaning the pump regularly is essential. Residue buildup can lead to clogs or even complete pump failure. Don't overlook the importance of proper calibration. Regularly calibrate the pump to ensure accurate flow rates.

Documentation is key for ongoing maintenance. Keep detailed records of inspections and repairs. This will help identify patterns and potential issues early. Reflect on any maintenance missed in the past. Learning from those oversights can improve the pump's performance and lifespan. Frequent training for staff on best practices is also beneficial. A well-informed team can spot issues before they escalate.

Related Posts

-

10 Unique Metering Pump Types You Should Know About

-

Understanding the Role of Industrial Metering Pumps in Modern Manufacturing Processes

-

How to Choose the Right Types of Pumps for Your Industrial Needs: A Comprehensive Guide

-

2025 Top 10 Chemical Metering Pumps for Precision Fluid Control

-

How to Choose the Right Commercial Pump for Your Business Needs

-

2025 Top Chemical Metering Pump System Insights and Innovations