Blog

How to Select the Right Injection Pumps for Your Industrial Needs

In the ever-evolving landscape of industrial operations, the selection of appropriate injection pumps is critical for optimizing efficiency and performance. According to a recent report by the Global Market Insights, the injection pump market is projected to surpass $7 billion by 2025, driven by increasing demand across various sectors such as oil and gas, chemicals, and wastewater management. As industries strive for precision in fluid delivery and enhanced operational reliability, understanding the diverse types of injection pumps— ranging from diaphragm to gear pumps—becomes essential. Notably, the correct selection can lead to significant cost savings and improved safety standards, making it a pivotal factor in successful project execution. This guide will delve into the key considerations and best practices for selecting the right injection pumps tailored to your industrial needs.

Key Factors to Consider When Choosing Injection Pumps for Industrial Applications

When selecting injection pumps for industrial applications, several key factors must be considered to ensure optimal performance and reliability. First and foremost, the type of fluid being pumped is crucial. Different fluids, such as corrosive chemicals or viscous materials, require specific pump designs and materials of construction to withstand operating conditions without failure.

Tip: Always review the compatibility of pump materials with the fluid being handled. This can help prevent costly equipment damage and ensure efficient operation.

Another important factor is the pump's flow rate and pressure requirements. It's essential to calculate the desired flow rate based on your operational needs, as under-sizing can lead to inadequate performance, while over-sizing may result in excess energy consumption and wear.

Tip: Conduct a thorough assessment of your system's requirements before finalizing a pump size. This will aid in selecting a pump that not only meets performance criteria but also enhances energy efficiency in the long run.

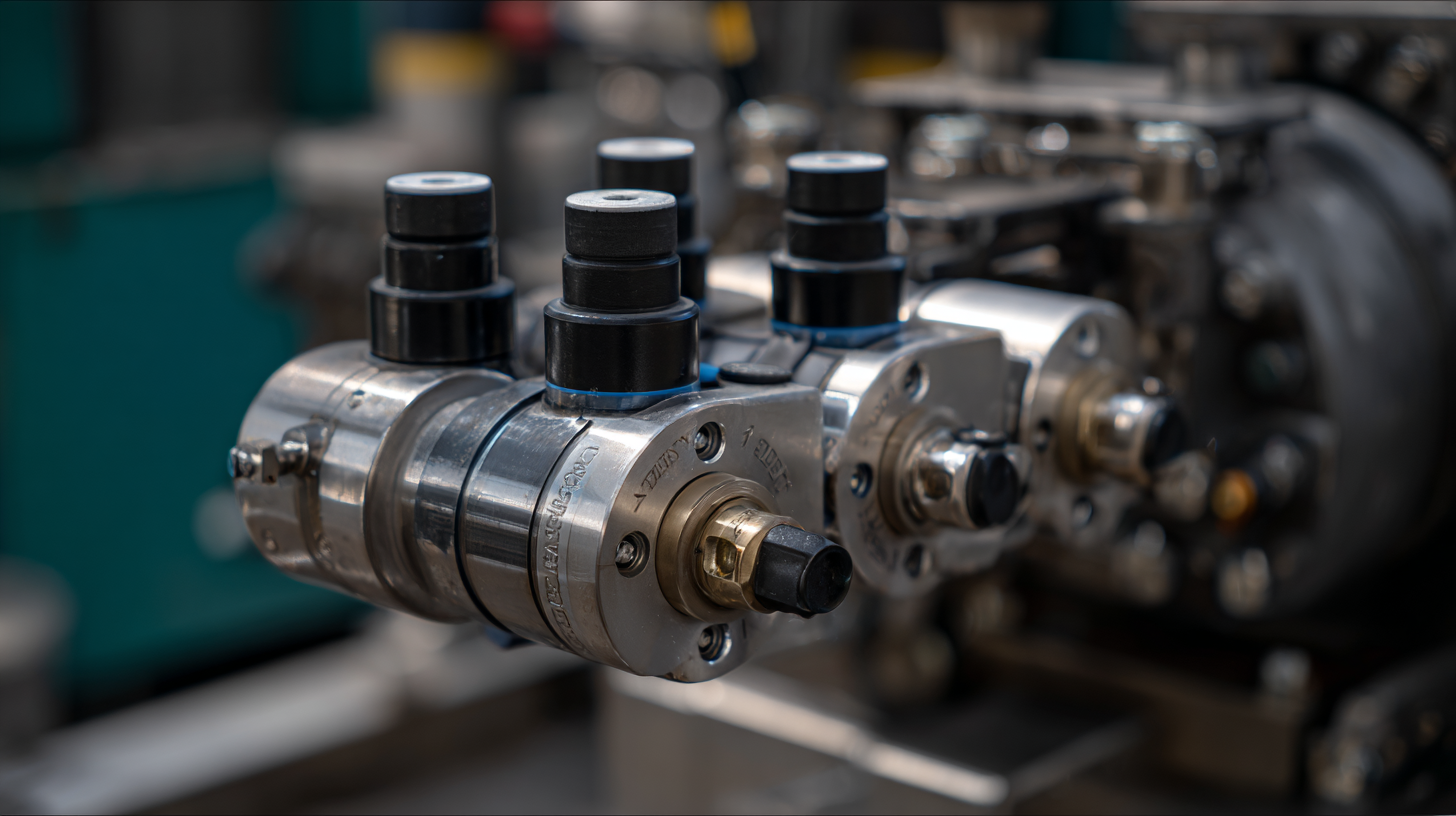

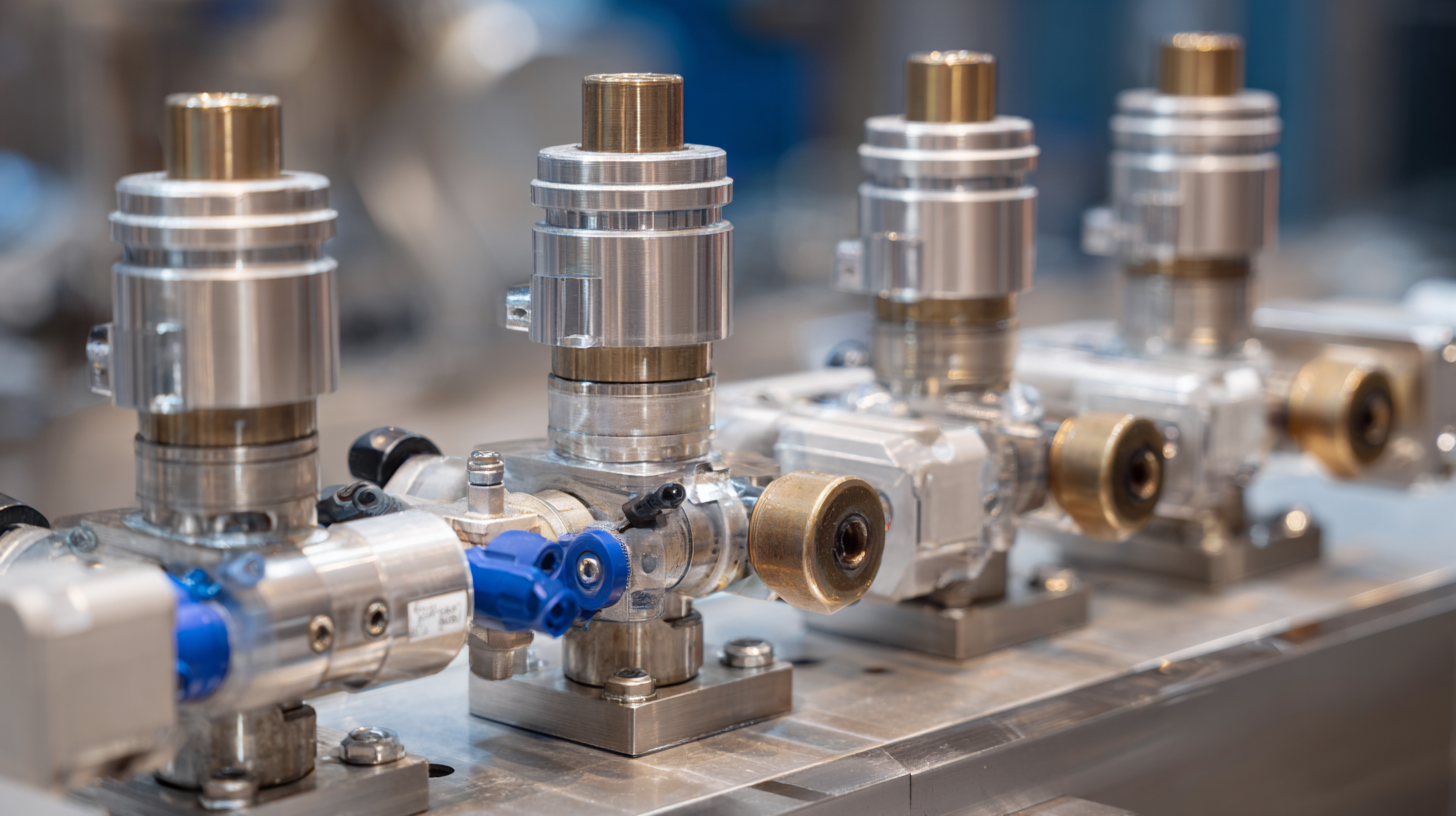

Understanding Different Types of Injection Pumps and Their Specific Uses in Industry

When selecting injection pumps for industrial applications, it is essential to understand the diverse types available and their specific utilities. Primarily, injection pumps can be categorized into positive displacement pumps and dynamic pumps. Positive displacement pumps, which include gear and diaphragm pumps, are typically praised for their ability to deliver a consistent flow rate regardless of the system pressure. According to a recent report by the Research Institute of Industrial Technologies, these pumps account for approximately 60% of the market for industrial injection systems due to their reliability and efficiency in handling viscous fluids.

On the other hand, dynamic pumps, such as centrifugal pumps, are preferred for applications that require high flow rates at lower viscosities. Their operational efficiency increases with the size of the system, making them ideal for processes like water treatment and chemical processing where large volumes are necessary. An analysis by the Global Pump Market Report indicates that the demand for centrifugal pumps is expected to grow by 4.5% annually through 2026, driven by advancements in manufacturing processes and the increased need for fluid transfer in various industries. Understanding these distinctions ensures that businesses can choose the most appropriate injection pump tailored to their operational needs.

How to Select the Right Injection Pumps for Your Industrial Needs

Evaluating Flow Rate and Pressure Requirements for Optimal Pump Selection

When selecting the right injection pumps for industrial applications, evaluating flow rate and pressure requirements is paramount. Flow rate, usually measured in liters per minute (LPM) or gallons per minute (GPM), dictates how quickly fluids can be injected into a system. According to the Hydraulic Institute, the required flow rate for various industrial processes can vary significantly; for instance, many chemical manufacturing operations may require flow rates ranging from 10 to 100 LPM, depending on the scale and specific requirements of the application.

Underestimating these needs can lead to inefficiencies or system failures.

When selecting the right injection pumps for industrial applications, evaluating flow rate and pressure requirements is paramount. Flow rate, usually measured in liters per minute (LPM) or gallons per minute (GPM), dictates how quickly fluids can be injected into a system. According to the Hydraulic Institute, the required flow rate for various industrial processes can vary significantly; for instance, many chemical manufacturing operations may require flow rates ranging from 10 to 100 LPM, depending on the scale and specific requirements of the application.

Underestimating these needs can lead to inefficiencies or system failures.

Pressure requirements are equally critical in ensuring optimal pump selection. Pressure, typically measured in pounds per square inch (PSI) or bar, affects the pump's ability to inject fluids against system resistance. Research published by the American Society of Mechanical Engineers (ASME) indicates that the chosen pump must meet or exceed the required pressure thresholds to avoid cavitation and ensure reliable operation. For example, in oil and gas applications, pressures can easily exceed 1500 PSI, necessitating robust pumps designed to handle such demands without compromise. By carefully assessing both flow rate and pressure needs, industries can make informed decisions that enhance operational efficiency and longevity of their equipment.

Analyzing Material Compatibility and Chemical Resistance for Long-Term Performance

When selecting injection pumps for industrial applications, understanding material compatibility and chemical resistance is crucial for ensuring long-term performance. Different fluids have varying chemical properties, and a pump's materials must be able to withstand these interactions without degrading. For instance, if a pump is used for handling corrosive substances, materials like stainless steel or certain plastics may be required to prevent deterioration and maintain efficiency. Therefore, assessing the chemical composition of the fluids will guide you in choosing the right materials for the pump components.

Furthermore, it is essential to consider not only the current fluids but also any potential future changes in the process. Industries often adapt to new materials or modify existing processes that may alter chemical exposure. Conducting thorough compatibility testing and researching manufacturers’ data on chemical resistance can prevent costly failures. Overall, focusing on material compatibility and chemical resistance will enhance the reliability of injection pumps, ensuring they can perform well under diverse and challenging industrial conditions.

Assessing Energy Efficiency Ratings and Cost Implications for Operational Budgeting

When selecting injection pumps for industrial needs, evaluating energy efficiency ratings is crucial for maintaining budgetary constraints. Energy efficiency directly impacts operational costs, and higher efficiency ratings typically indicate lower energy consumption during operation. By investing in energy-efficient pumps, companies can significantly reduce their electricity expenses over time, which is essential for a sustainable budget strategy. Analyzing the efficiency curves of different models enables decision-makers to choose pumps that not only meet flow and pressure requirements but also align with energy-saving goals.

Furthermore, the initial cost of injection pumps should be weighed against their long-term operational costs. While some high-efficiency pumps may come with a higher upfront price tag, their lower energy consumption and reduced maintenance needs often lead to savings that outweigh the initial investment over their lifespan. A thorough cost-benefit analysis can help in understanding the total cost of ownership, ensuring that the best decision is made not only for performance but also for economic viability.

Related Posts

-

7 Essential Tips for Choosing the Right Chemical Mixer for Your Industry Needs

-

How to Choose the Right Industrial Pumps for Your Manufacturing Needs

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

Ultimate Guide to Choosing the Right Chemical Mixer: Key Features and Industry Insights