Blog

How to Optimize Chemical Feed Systems for Maximum Efficiency?

Optimizing chemical feed systems is crucial for efficiency. These systems play a vital role in industries like water treatment, pharmaceuticals, and agriculture. Their performance directly affects overall production and cost-effectiveness.

Many facilities struggle with inefficiencies in their chemical feed systems. Issues can arise from improper dosing, outdated equipment, or poor maintenance practices. A small adjustment can lead to significant improvements. Regular monitoring can identify hidden inefficiencies, but often goes overlooked.

To achieve maximum efficiency, it's essential to conduct thorough evaluations and implement best practices. This includes selecting the right equipment and ensuring accurate dosing. Cleanliness and regular servicing also contribute significantly. Reflection on existing practices can uncover areas for enhancement, driving better outcomes in chemical feed systems.

Understanding the Basics of Chemical Feed Systems and Their Importance

Chemical feed systems play a critical role in various industries. They ensure precise dosing of chemicals into processes. This precision helps maintain product quality and operational efficiency. Understanding these systems is essential for improving performance.

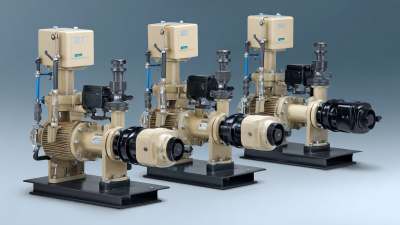

A chemical feed system consists of several components. These include pumps, injectors, and control systems. Each must be optimized for maximum efficiency. For example, a poorly calibrated pump can cause chemical waste or insufficient dosing. Regular maintenance checks are often overlooked but are vital for longevity and efficiency.

Operators sometimes underestimate the importance of monitoring. Real-time data can reveal inefficiencies. Observations like fluctuations in chemical levels should prompt immediate action. Understanding these underlying principles is key to unlocking better system performance. Continuous learning and adaptation can lead to significant gains in efficiency and cost savings.

How to Optimize Chemical Feed Systems for Maximum Efficiency?

| Parameter | Description | Optimal Value | Current Value | Status |

|---|---|---|---|---|

| Flow Rate | Rate at which the chemical is fed into the system | 200 L/h | 180 L/h | Below Optimal |

| Chemical Concentration | Percentage of active chemical in the feed | 5% | 4% | Below Optimal |

| Pump Efficiency | Efficiency rate of the chemical feed pump | 90% | 85% | Below Optimal |

| System Pressure | Pressure within the chemical feed system | 50 psi | 45 psi | Below Optimal |

| Maintenance Frequency | How often the system is serviced | Monthly | Every 6 weeks | Requires Improvement |

Identifying Key Factors Affecting Efficiency in Chemical Feed Systems

Chemical feed systems play a crucial role in various industrial processes. Understanding key factors affecting their efficiency can yield significant benefits. Flow rate, dosage accuracy, and system design are primary determinants of performance. According to the Chemical Engineering Journal, inefficient feed systems can lead to a 15% reduction in overall process efficiency.

One common issue is the flow consistency. Fluctuations can disrupt the chemical reactions, causing unstable outputs. A study indicates that 40% of facilities experience inconsistent flow rates due to equipment malfunction or design flaws. Regular maintenance and real-time monitoring are essential. Utilizing advanced monitoring tools can help identify discrepancies quickly.

Another factor is the precision of chemical dosing. Studies have shown that improper dosing can result in increased waste. This not only raises costs but can also compromise product quality. Companies should assess their dosing technologies regularly. Inefficient systems can severely impact profitability and reliability in production. Addressing these efficiency dynamics is imperative for optimal performance.

Techniques for Improving Accuracy in Chemical Feed Measurement

Optimizing chemical feed measurement is crucial for efficiency. Accurate dosing significantly impacts overall system performance. According to industry studies, improper dosing can lead to a 15-20% increase in raw material costs. This highlights the need for precise measurement techniques.

One effective technique is using advanced flow meters. These devices can improve measurement accuracy by 5-10%. They provide real-time data and reduce human error. Regular calibration of these meters is essential for maintaining accuracy, but many facilities neglect this step. This oversight can lead to significant discrepancies in feed rates.

Another area to consider is the installation and maintenance of piping systems. Blockages or leaks can distort measurements. Implementing regular maintenance schedules is often overlooked. Studies reveal that 30% of measurements may become inaccurate due to such issues. Addressing these aspects can lead to more reliable chemical feed systems. It's important to constantly review current practices for improvement opportunities.

Regular Maintenance Practices to Enhance System Performance

Regular maintenance is essential for optimizing chemical feed systems. It ensures reliable performance and enhances efficiency. According to the American National Standards Institute (ANSI), regular system checks can reduce downtime by up to 30%. These checks help identify potential issues before they escalate. A small leak or valve malfunction can lead to significant inefficiencies.

One effective practice is to schedule quarterly inspections. Checking calibration, inspecting pumps, and monitoring flow rates are critical. Industry studies show that improper calibration can decrease efficiency by 15%. Filtering systems should not be overlooked. Clean filters can improve flow and minimize pressure loss. However, many operations fail to monitor filter conditions regularly. This can result in unexpected maintenance costs.

Training personnel on proper maintenance is equally vital. Regular workshops can bridge the knowledge gap. Data shows that 20% of chemical feed failures stem from operator error. Investing in staff education can mitigate this risk. Regular performance assessments can also reveal system weaknesses. If ignored, these weaknesses may lead to costly downtimes and repairs. Optimizing chemical feed systems is a continuous journey, not a one-time fix.

Utilizing Technology and Automation for Optimal Chemical Feed Control

In today’s industrial landscape, optimizing chemical feed systems is crucial. Utilizing technology and automation can enhance chemical feed control significantly. Advanced sensors and real-time monitoring tools can help maintain precise chemical dosing. According to a report by the American Chemistry Council, plants that employ automation can achieve up to a 25% reduction in operational costs.

Automation streamlines operations and minimizes human error. It allows for consistent performance and data collection for analysis. Smart systems can adjust feed rates based on real-time demand. For instance, if the process requires an increase in chemical concentration, automated systems can react instantly, eliminating lag time.

**Tips:** Regularly update software to harness new features. Integrate predictive analytics to foresee issues before they arise. Investing in employee training ensures that operators can utilize these advanced tools effectively. Reflecting on system performance can reveal areas for improvement. Sometimes, technology may not capture unique environmental factors, which must be manually adjusted. Balancing technology with human insight is essential for optimal efficiency.

Related Posts

-

2025 Top 5 Chemical Metering Solutions for Precision and Efficiency

-

Top 10 Chemical Metering Solutions for Accurate and Efficient Measurement

-

7 Essential Tips for Choosing the Right Chemical Injection Pumps

-

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety

-

2025 Top Chemical Metering Pump System Insights and Innovations

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China