Blog

Innovative Applications of Diaphragm Pumps Across Various Industries

In the ever-evolving landscape of industrial technology, diaphragm pumps have emerged as essential components across a multitude of sectors, from pharmaceuticals to wastewater management. These versatile and innovative devices utilize a flexible diaphragm to create a suction mechanism, allowing for the efficient transfer of fluids, including corrosive and viscous materials. As industries strive for improved efficiency and sustainability, the application of diaphragm pumps has expanded, showcasing their robustness and adaptability.

This ultimate guide delves into the diverse and innovative applications of diaphragm pumps, highlighting their role in optimizing processes, enhancing safety, and meeting the unique demands of various industries. Join us as we explore how these pumps are revolutionizing fluid management and driving progress across different fields, and discover why they are becoming indispensable in modern industrial operations.

Exploring Diaphragm Pumps: A Comprehensive Overview of Types and Mechanisms

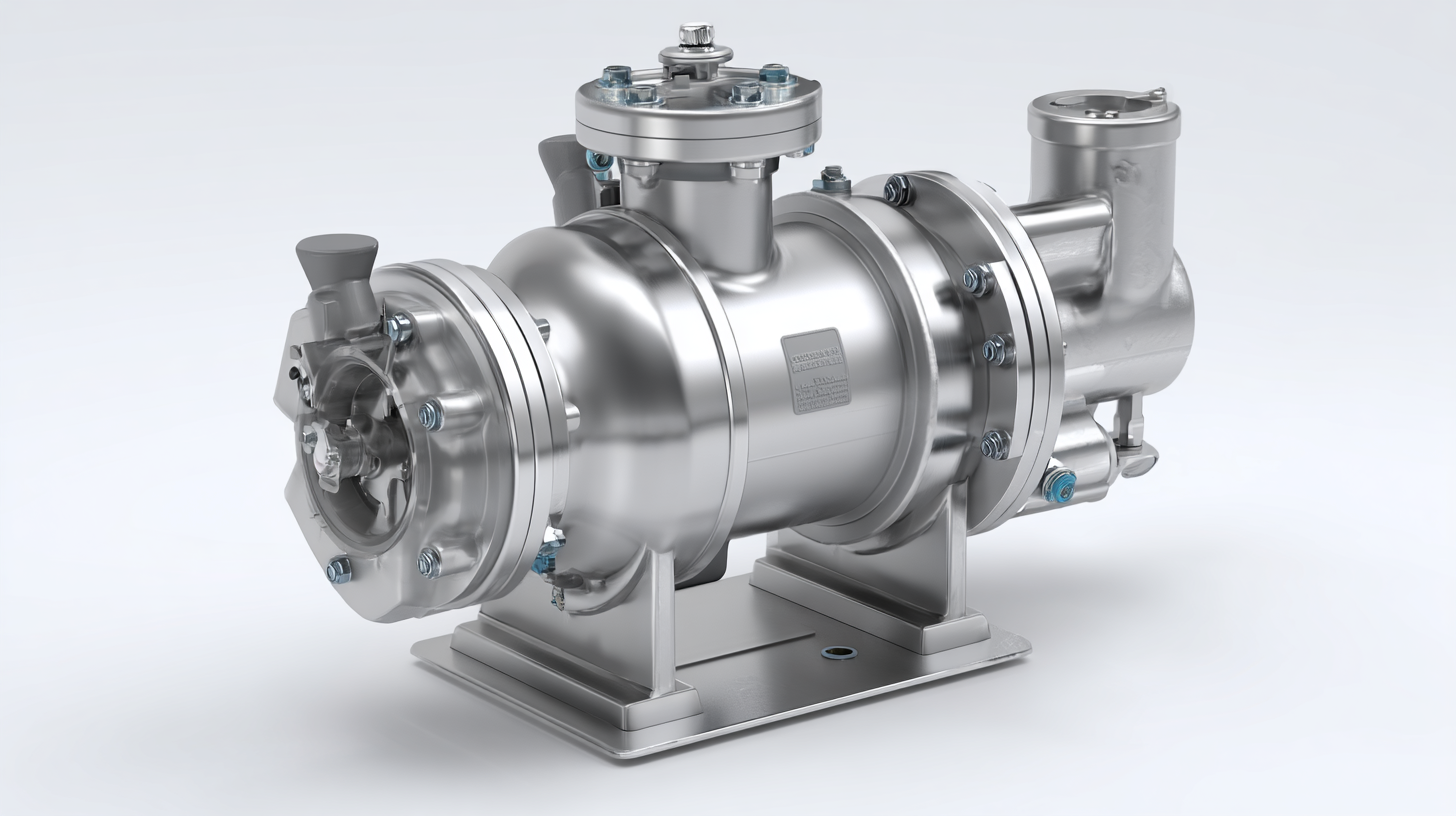

Diaphragm pumps have emerged as a versatile solution across various sectors, owing to their unique mechanisms and adaptability. These positive displacement pumps operate by utilizing a flexible diaphragm that moves back and forth to create a vacuum, thus drawing fluid into the chamber and expelling it through the discharge port. This system not only safeguards the fluid from contamination but also ensures consistent flow rates, making diaphragm pumps an ideal choice for industries like pharmaceuticals, food and beverage, and wastewater treatment. According to a recent market report, the global diaphragm pump market is projected to reach USD 4.87 billion by 2027, growing at a CAGR of 4.2% from 2020.

Different types of diaphragm pumps, including air-operated double-diaphragm (AODD) and electrically operated diaphragm pumps, cater to specific industry needs. AODD pumps, for instance, are designed for handling abrasive, viscous, or corrosive fluids without the risk of leakage, making them highly effective in chemical processing. Meanwhile, electrically operated diaphragm pumps have gained popularity in the food industry for their precise flow control, ensuring product safety and compliance with stringent regulations. As industries evolve and demand for efficient fluid management solutions increases, diaphragm pumps will continue to play a pivotal role in maintaining operational excellence across various applications.

Innovative Applications of Diaphragm Pumps Across Various Industries

This chart illustrates the distribution of diaphragm pump applications across different sectors, highlighting their versatile functionalities. The data showcases the percentage share of diaphragm pumps used in various industries.

Key Industries Leveraging Diaphragm Pumps for Enhanced Efficiency

Diaphragm pumps are finding innovative applications across various industries, significantly boosting efficiency and reliability in fluid handling processes. Key sectors such as construction, semiconductors, and water management are increasingly leveraging the advantages offered by these pumps. For instance, the global market for diaphragm pumps is experiencing growth amidst competition from alternative pumps like submersible and agitation pumps, indicating a niche yet vital role for diaphragm technologies.

Diaphragm pumps are finding innovative applications across various industries, significantly boosting efficiency and reliability in fluid handling processes. Key sectors such as construction, semiconductors, and water management are increasingly leveraging the advantages offered by these pumps. For instance, the global market for diaphragm pumps is experiencing growth amidst competition from alternative pumps like submersible and agitation pumps, indicating a niche yet vital role for diaphragm technologies.

In construction, the market for pumps is projected to reach approximately $6.9 billion by 2030. This growth is fueled by the demand for effective water management solutions and the need for robust pumping systems that can handle harsh conditions. Similarly, in the semiconductor industry, diaphragm pumps are integral for processes such as chemical handling and cleaning applications. The market for semiconductor pumps is expanding, with diaphragm pumps being prominently featured due to their precision and reliability.

Additionally, the rapidly evolving electrically-operated diaphragm pump solutions present opportunities for enhanced energy efficiency in various applications. As companies continue to adopt innovative fluid handling technologies, diaphragm pumps will undoubtedly remain a critical component for enhanced operational performance across multiple industries.

Innovative Applications: How Diaphragm Pumps Are Transforming Manufacturing Processes

In today's rapidly evolving industrial landscape, diaphragm pumps are playing a pivotal role in transforming manufacturing processes across various sectors. According to a report by MarketsandMarkets, the diaphragm pump market is projected to reach USD 4.35 billion by 2025, growing at a CAGR of 6.5%. This growth is largely driven by the demand for efficient and reliable fluid transfer solutions that are crucial in environments where precision and cleanliness are paramount.

Manufacturers are increasingly adopting diaphragm pumps for their ability to handle a wide range of liquids, including corrosive chemicals and viscous materials, without compromising the quality of the product. For instance, in the pharmaceutical industry, where maintaining sterility is essential, diaphragm pumps ensure that the materials processed are free from contamination. A study from Grand View Research highlighted that the use of diaphragm pumps in pharmaceuticals is expected to expand significantly, propelled by the rise of biologics and biopharmaceuticals, which require precision in dosing and transfer. This adoption is not limited to pharmaceuticals; industries such as food and beverage are equally reaping the benefits, leveraging diaphragm pumps to ensure the safe handling of liquids while adhering to stringent hygiene standards.

Environmental Benefits of Diaphragm Pumps in Sustainable Practices

Diaphragm pumps are emerging as a crucial component in sustainable practices across various industries, thanks to their ability to handle a wide range of fluids while minimizing environmental impact. These pumps are designed to operate efficiently with lower energy consumption compared to traditional pump systems. By utilizing a simple yet effective mechanism that allows for thorough fluid transfer without the need for electricity in some models, diaphragm pumps significantly reduce greenhouse gas emissions associated with industrial processes.

Moreover, diaphragm pumps excel in managing hazardous and corrosive materials, thereby enhancing workplace safety and reducing the risk of environmental contamination. Their ability to operate dry or handle abrasive materials means that companies can avoid frequent maintenance and potential failures that could lead to spills or leaks. This reliability not only protects natural resources but also helps businesses comply with increasingly stringent environmental regulations, further promoting sustainable industrial practices. By integrating diaphragm pumps into their systems, industries are taking a significant step towards a more sustainable future while maintaining operational efficiency.

Future Trends: The Evolving Role of Diaphragm Pumps in Industrial Applications

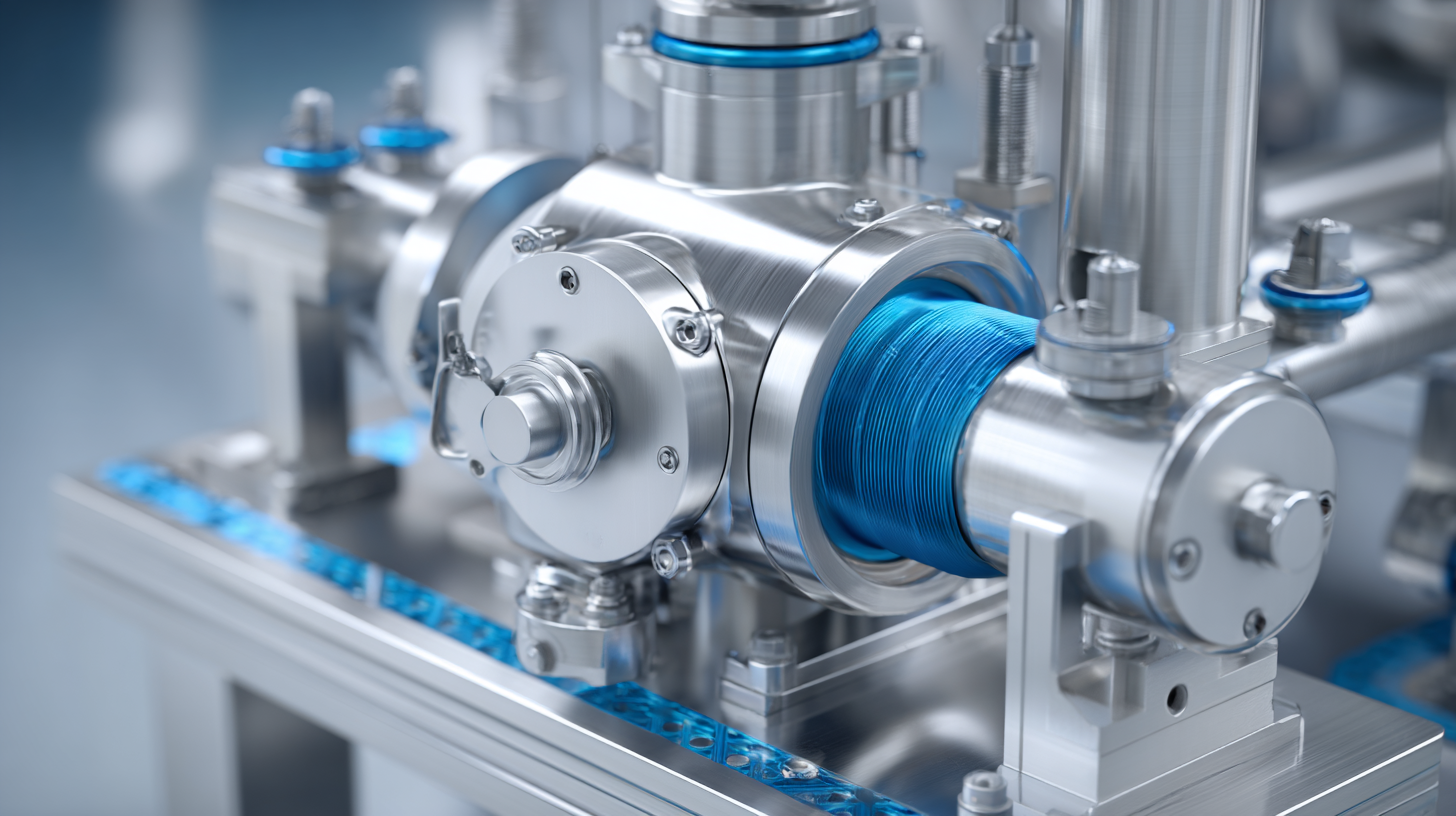

The evolving role of diaphragm pumps in industrial applications showcases a shift towards more efficient and sustainable solutions. As industries increasingly prioritize eco-friendly practices, diaphragm pumps are stepping up to meet these demands. Their ability to handle a wide range of fluids, including those that are viscous or abrasive, makes them indispensable in sectors such as chemical processing, pharmaceuticals, and food production. Future trends indicate that advancements in materials and technology will enhance the durability and efficiency of diaphragm pumps, allowing them to perform in even more challenging environments.

Moreover, the integration of smart technology into diaphragm pumps is set to revolutionize their use in various sectors. With the rise of the Internet of Things (IoT), companies can expect real-time monitoring and data analytics features that improve operational efficiency and reduce maintenance costs. This not only aids in preventive maintenance but also contributes to the overall reduction of operational downtime. As businesses look for innovative ways to increase their productivity while minimizing environmental impact, diaphragm pumps are emerging as a key player in achieving these goals.

Related Posts

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

5 Essential Benefits of Using a Chemical Mixer for Your Manufacturing Process

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

Innovative Solutions for Industrial Pumps to Enhance Efficiency and Reduce Costs