Blog

Understanding the Role of Industrial Metering Pumps in Modern Manufacturing Processes

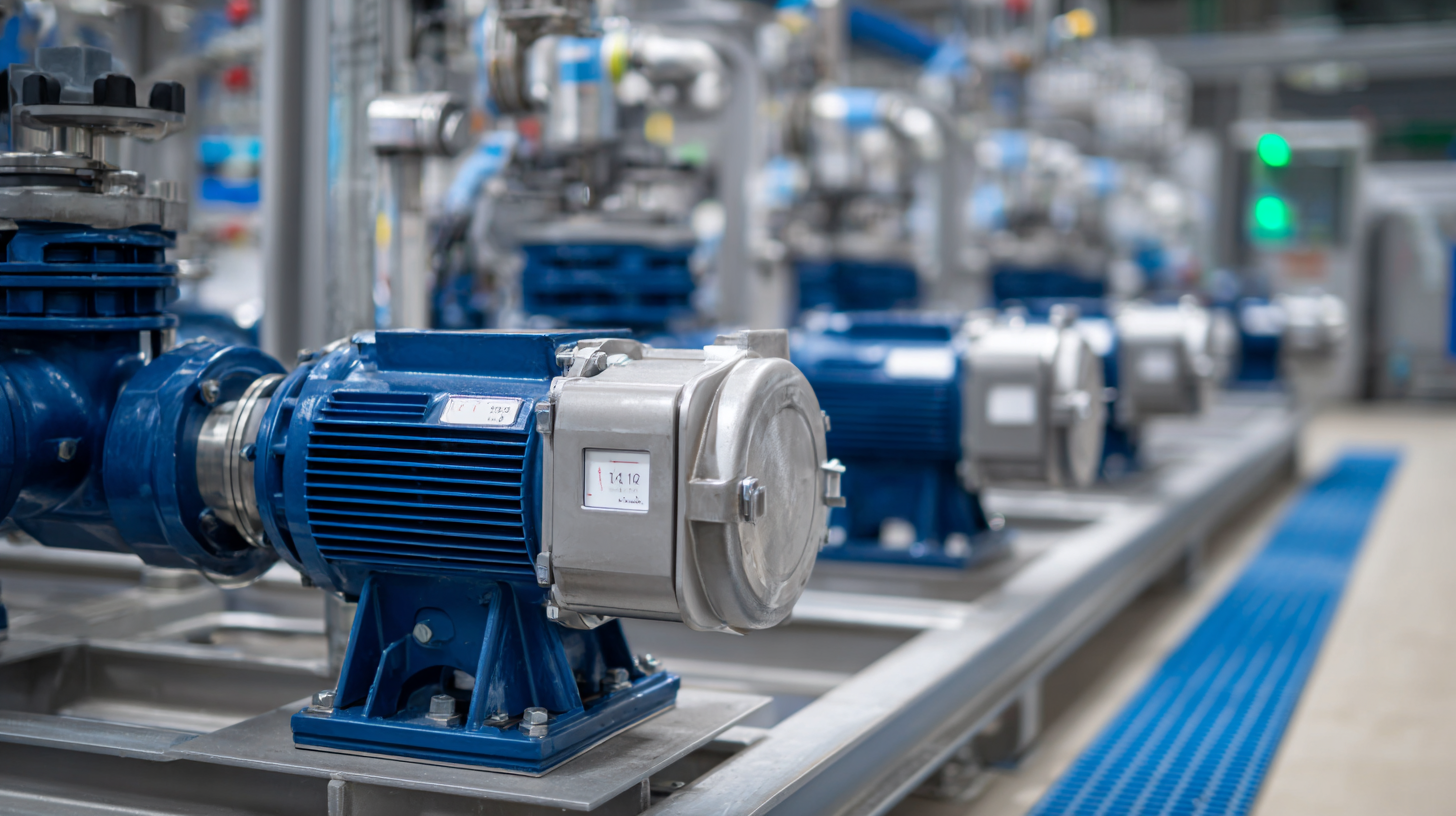

In today's rapidly evolving manufacturing landscape, the integration of advanced technologies is essential for enhancing efficiency and productivity. Among these innovations, the industrial metering pump stands out as a critical component in the precise handling of fluids across various processes. According to a report by MarketsandMarkets, the metering pump market is projected to reach USD 7.5 billion by 2026, driven by the increasing demand for accurate dosing in sectors such as chemicals, water treatment, and food production. These pumps not only ensure the optimal flow rates necessary for maintaining product quality but also contribute to energy savings and reduced operational costs. As industries strive for greater automation and precision, understanding how to effectively implement and utilize industrial metering pumps becomes imperative for modern manufacturers aiming to stay competitive.

The Evolution of Industrial Metering Pumps in Modern Manufacturing

The evolution of industrial metering pumps has been a significant aspect of advancements in modern manufacturing processes. Initially, these pumps were primarily mechanical devices with limited precision, often causing inconsistencies in product quality. However, as manufacturing demands have become more complex and the need for accuracy increases, metering pump technology has undergone substantial transformations. Modern metering pumps are equipped with advanced control systems, enabling them to provide precise flow rates and adapt to varying operational conditions seamlessly.

In recent years, the integration of digital technologies has revolutionized the functionality of industrial metering pumps. Today's pumps utilize smart sensors and advanced monitoring solutions, allowing for real-time adjustments and data analytics. This not only enhances operational efficiency but also reduces waste and ensures compliance with stringent industry regulations. As industries continue to evolve towards more sustainable practices, the role of innovative metering pumps becomes increasingly critical, allowing manufacturers to optimize resource usage while maintaining high-quality outputs. The journey of industrial metering pumps reflects a broader trend in manufacturing, highlighting the importance of precision and adaptability in the face of ever-changing market demands.

Understanding the Role of Industrial Metering Pumps in Modern Manufacturing Processes

| Dimension | Details |

|---|---|

| Type of Pump | Diaphragm, Gear, Screw |

| Application Area | Chemical Processing, Water Treatment, Food & Beverage |

| Flow Rate | 0.1 to 2000 L/h |

| Pressure Range | Up to 15 Bar (220 PSI) |

| Key Features | Accurate dosing, Chemical compatibility, Modular design |

| Energy Efficiency | 80% Efficient |

| Maintenance Frequency | Every 6 months |

| Cost | $500 - $5000 |

Key Applications of Metering Pumps in Various Industries

Metering pumps play a crucial role in various manufacturing processes across multiple industries. These precision-driven devices are designed to deliver consistent and controlled fluid flow, making them indispensable in applications such as chemical dosing, solvent transfer, and water treatment. In the pharmaceutical industry, for instance, metering pumps are utilized to ensure accurate dosing of ingredients, which is vital for product safety and effectiveness. Additionally, in the food and beverage sector, they help maintain consistent flavors and preservatives by delivering precise amounts of additives.

Metering pumps play a crucial role in various manufacturing processes across multiple industries. These precision-driven devices are designed to deliver consistent and controlled fluid flow, making them indispensable in applications such as chemical dosing, solvent transfer, and water treatment. In the pharmaceutical industry, for instance, metering pumps are utilized to ensure accurate dosing of ingredients, which is vital for product safety and effectiveness. Additionally, in the food and beverage sector, they help maintain consistent flavors and preservatives by delivering precise amounts of additives.

Tips: When selecting a metering pump, consider factors such as flow rate, pressure requirements, and fluid characteristics to ensure optimal performance for your specific application.

In the oil and gas sector, metering pumps are essential for boosting efficiency in hydraulic fracturing and enhanced oil recovery processes. Their ability to handle corrosive fluids and high-pressure environments makes them particularly valuable. Furthermore, in wastewater treatment, they facilitate the accurate injection of chemicals for neutralization and disinfection, contributing to environmental sustainability.

Tips: Regular maintenance and calibration of metering pumps can significantly enhance their longevity and accuracy, reducing downtime and operational costs.

Advancements in Metering Pump Technology for Enhanced Efficiency

Advancements in metering pump technology have significantly transformed modern manufacturing processes, enabling enhanced efficiency and precision. These innovations encompass a range of improvements, including the development of smart pumps equipped with IoT capabilities. By integrating sensors and connectivity features, manufacturers can monitor pump performance in real-time, optimize fluid delivery, and reduce downtime, leading to increased productivity.

Furthermore, advancements in materials and design have resulted in metering pumps that offer greater reliability and are capable of handling a wider variety of fluids, including corrosive and viscous substances. The introduction of advanced control systems allows for more accurate flow rate adjustments, ensuring that each process receives the exact amount of fluid required. As a result, industries are experiencing lower operational costs and reduced waste, reinforcing the crucial role of metering pumps in achieving streamlined manufacturing operations.

Comparative Analysis of Digital vs. Analog Metering Solutions

The comparative analysis of digital versus analog metering solutions highlights the transformative impact that advancements in technology have had on industrial metering pumps. Digital metering systems offer greater precision, remote monitoring capabilities, and enhanced data analytics compared to traditional analog meters. This is particularly significant in modern manufacturing processes where efficiency and real-time data are critical for optimizing operations and minimizing waste.

Moreover, the projected growth of the global digital power meter market underscores the increasing reliance on digital solutions across various sectors. With a significant CAGR predicted, industries are adopting digital transformation strategies to overcome challenges linked to energy management and resource allocation. In countries like Germany, the rollout of smart meters demonstrates a commitment to enhancing energy efficiency and driving sustainable practices. These smart solutions not only improve accuracy in billing and consumption tracking but also empower users with actionable insights, thereby supporting the energy transition efforts and fostering a more sustainable manufacturing landscape.

Comparison of Digital and Analog Metering Pumps in Manufacturing Processes

Strategies for Optimal Integration of Metering Pumps in Manufacturing Systems

In modern manufacturing systems, the integration of

industrial metering pumps

plays a critical role in enhancing efficiency and precision. To achieve optimal integration, manufacturers must first conduct a thorough analysis of their processes to identify the specific fluid transfer requirements. Understanding the viscosity, flow rates, and chemical compatibility of the fluids involved allows for the selection of the appropriate pump type. This tailored approach ensures seamless operation and minimizes potential system failures.

Additionally, implementing

automation technologies

can significantly improve the effectiveness of metering pump integration. By incorporating

programmable logic controllers (PLCs)

and real-time monitoring systems, manufacturers can dynamically adjust pump operations based on fluctuating production needs. Such advancements not only boost productivity but also provide valuable data for ongoing optimization.

Regular maintenance schedules and operator training further enhance the reliability of these systems, ensuring that metering pumps contribute positively to the overall manufacturing workflow.

Related Posts

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency

-

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety