Blog

What is the Importance of Pump Accessories in Efficiency?

In the world of industrial operations, pump accessories play a crucial role. These components significantly enhance pump efficiency. Without the right accessories, even the best pumps can underperform. Strained systems lead to increased energy costs and reduced productivity.

The importance of pump accessories cannot be overstated. They help in maintaining optimal flow rates and pressure levels. A simple accessory can transform a system, ensuring it runs smoothly. However, many overlook this critical aspect. Often, businesses focus on the pump alone, neglecting necessary accompaniments. This oversight can lead to operational inefficiencies.

Specific accessories, such as valves and filters, ensure reliability. They protect pumps from contaminants and control flow direction. Yet, not all pumps need the same accessories. It's a journey of trial and error to choose the right ones. Businesses must reflect on their current setups. Do they truly understand the value of these essential components? This question is vital for enhancing overall efficiency.

Understanding Pump Accessories and Their Functionality

Pump accessories play a crucial role in optimizing performance. They enhance the functionality of the pump system. From valves to gauges, each component ensures efficient operation. For instance, check valves prevent backflow, maintaining consistent flow direction. Pressure gauges help monitor the system's health, alerting users to issues.

Understanding these components is essential for maintenance. Regular inspection is vital but often neglected. Users might overlook minor leaks or wear and tear. This can lead to inefficiencies or costly repairs. It's important to recognize that even small accessories can significantly impact overall productivity.

Some accessories enhance usability. Filters keep foreign particles out, which is vital for pump longevity. Strainers serve a similar purpose. Upgrading or replacing these components can yield better efficiency. However, sometimes the upgrades come with challenges, like compatibility issues. Users must weigh these factors carefully.

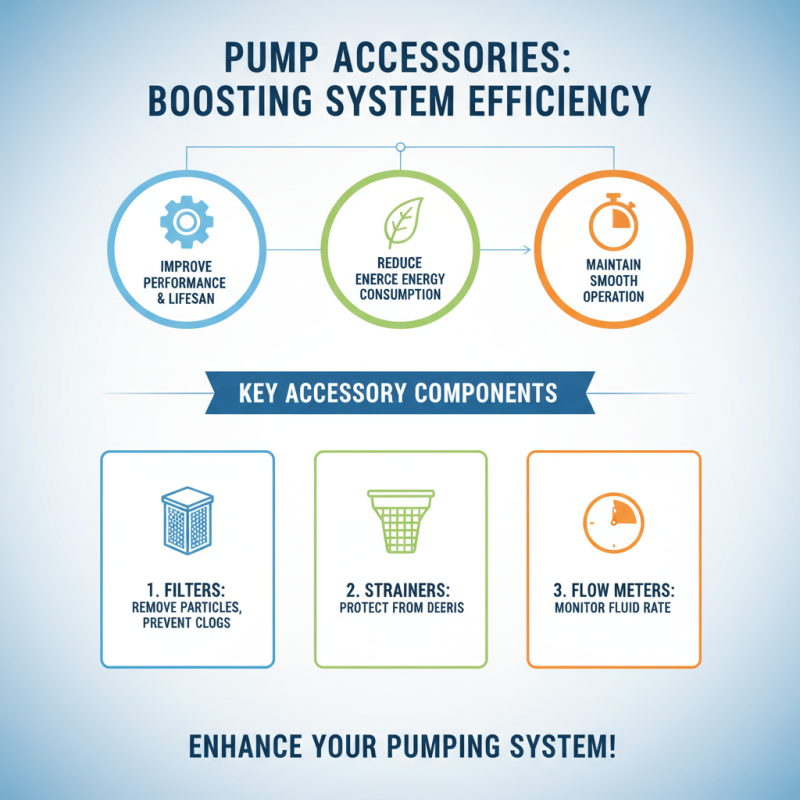

Key Pump Accessories and Their Roles in Enhancing Efficiency

Pump accessories play a crucial role in enhancing the overall efficiency of pumping systems. These components help improve performance, reduce energy consumption, and prolong the lifespan of the pump. Key accessories include filters, strainers, and flow meters. Each of these plays an essential role in maintaining smooth operation. A filter removes unwanted particles. This prevents clogs and wear in the pump.

Strainers are vital for protecting the pump from debris. They ensure that only clean fluids reach the pump's internals. This can lead to significant savings over time. Flow meters monitor real-time performance, allowing operators to optimize settings for efficiency. An inefficient pump may use more energy than necessary. Increased wear can lead to costly repairs.

**Tips:** Regular maintenance of accessories is a must. Check filters monthly. Clean or replace them as needed. Consider investing in high-quality strainers. They can make a noticeable difference in efficiency.

Pump efficiency is not automatic. You must make adjustments as required. Sometimes, the issue stems from poorly maintained accessories. Track performance meticulously. Small changes can yield big results in efficiency and cost-effectiveness.

Impact of High-Quality Accessories on Pump Performance

High-quality pump accessories play a critical role in enhancing pump performance. They can significantly boost efficiency, leading to lower operational costs. A well-chosen accessory, such as a reliable seal or a quality filter, greatly impacts the pump's lifespan. For instance, a sturdy seal prevents leakage. This not only conserves energy but also minimizes downtime for repairs.

Investing in good accessories can save money in the long run. However, it's important to remember that not all accessories guarantee improved performance. Some may lack compatibility with specific pump models. This mismatch can lead to inefficiencies. Regularly assessing the condition of accessories is vital to ensure optimal performance.

Maintenance can also be overlooked or improperly executed. Regular inspections and timely replacements are crucial. Ignoring wear and tear affects pump operations. Quality accessories enhance performance, yet poor choices can diminish efficiency. A careful selection process and mindful maintenance approach can lead to better results.

What is the Importance of Pump Accessories in Efficiency? - Impact of High-Quality Accessories on Pump Performance

| Accessory Type | Impact on Efficiency (%) | Material Quality | Common Issues Without Accessory |

|---|---|---|---|

| Pump Seal | 15 | High-grade elastomer | Leakage, reduced pressure |

| Impeller | 25 | Corrosion-resistant alloy | Cavitation, vibration |

| Strainer | 10 | Stainless steel | Blockages, flow restriction |

| Bearing | 20 | Ceramic-coated | Increased wear, noise |

| Control Valve | 30 | High-performance polymer | Poor flow regulation, energy waste |

Maintenance Practices for Optimal Pump Accessory Efficacy

Pump accessories play a crucial role in enhancing efficiency and performance. Regular maintenance of these components is essential. According to a report from the Hydraulic Institute, over 25% of pump failures are linked to accessory malfunctions. This highlights the need for diligent upkeep.

Proper maintenance practices start with regular inspections. Check seals, bearings, and filters for wear. Replace any faulty parts immediately. Data shows that preventive maintenance can increase pump lifespan by up to 50%. Neglecting these small components can lead to bigger problems down the line. Ignoring signs of wear will result in costly repairs.

Training personnel is also important. Many operators overlook basic maintenance steps. Simple tasks, like cleaning and lubricating, are often neglected. A survey indicated that 60% of operators are unaware of proper techniques. Investing time in education can greatly improve efficacy. Implementing these practices can lead to significant efficiency gains.

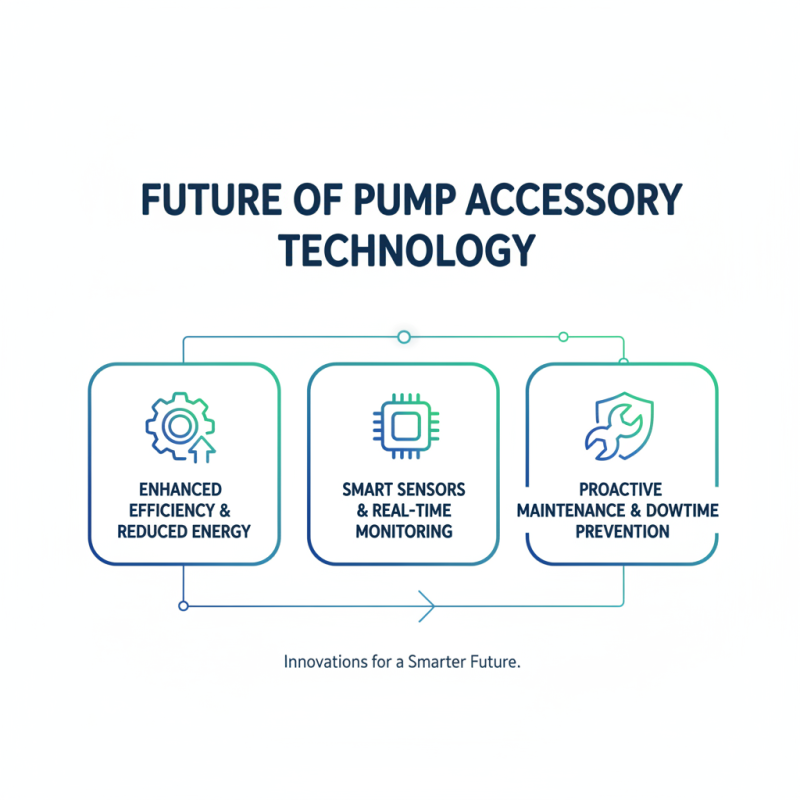

Future Trends in Pump Accessory Technology and Efficiency Solutions

The future of pump accessory technology is promising. Innovations focus on enhancing efficiency and reducing energy consumption. Smart sensors are becoming common. These devices monitor performance in real time. They can alert operators to potential issues before they escalate. This proactive approach prevents costly downtime.

Hybrid systems are gaining traction as well. By combining traditional pumps with renewable energy sources, they reduce reliance on non-renewable energy. This shift in focus is important for sustainability. However, implementing these technologies can be challenging. The initial cost may deter some users.

As efficiency solutions evolve, companies must adapt. Training staff on new technologies remains essential. The learning curve can be steep. Mistakes in installation or maintenance can lead to inefficiencies. Continuous evaluation and adaptation are part of this process. Embracing change is not easy, but it’s vital for staying competitive.

Related Posts

-

Harnessing Innovation in Pump Accessories at the 138th Canton Fair 2025 with Market Insights Driving Growth

-

How to Choose the Best Pump Accessories for Optimal Performance and Efficiency

-

Top 10 Essential Pump Accessories You Need for Optimal Performance?

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China

-

Top Pump Systems for Efficient Water Management Solutions

-

How to Select the Right Injection Pumps for Your Industrial Needs