Blog

Understanding the Importance of Metering Pumps in Modern Industrial Applications

In the landscape of modern industrial applications, the significance of metering pumps cannot be overstated. As industries increasingly focus on precision and efficiency, metering pumps have emerged as critical components that ensure accurate fluid dispensing and management. According to a recent market research report by Grand View Research, the global metering pumps market was valued at approximately $5.55 billion in 2021 and is projected to expand at a CAGR of 6.9% from 2022 to 2030. The ability of metering pumps to deliver precise volumes of liquids, thereby reducing waste and enhancing operational efficiency, makes them indispensable in sectors ranging from water treatment to pharmaceuticals. As industries strive for improved process optimization and sustainability, the role of metering pumps will continue to grow, underscoring their importance in the pursuit of innovative solutions to complex challenges.

The Critical Role of Metering Pumps in Precision Chemical Dispensing

Metering pumps play a critical role in precision chemical dispensing across various industrial applications. These pumps are designed to deliver precise volumes of liquids, making them essential in processes where accuracy is crucial, such as in pharmaceuticals, water treatment, and food processing. According to a report by Grand View Research, the global metering pump market size was valued at approximately $6.2 billion in 2022 and is expected to grow significantly, driven by the increasing demands for process automation and quality control in manufacturing settings.

The functionality of metering pumps ensures that chemicals are dispensed at the correct rates, minimizing waste and optimizing resource efficiency. For instance, the American Chemical Society notes that improper chemical dispensing can lead to significant financial losses and environmental hazards. With metering pumps, industries can achieve dosing precision within ±1%, which is vital for maintaining product quality and compliance with stringent regulatory standards. As industrial processes continue to evolve, the demand for reliable and accurate metering solutions only stands to increase, emphasizing the indispensable role of these pumps in modern applications.

Key Advantages of Metering Pumps Over Traditional Pumping Systems

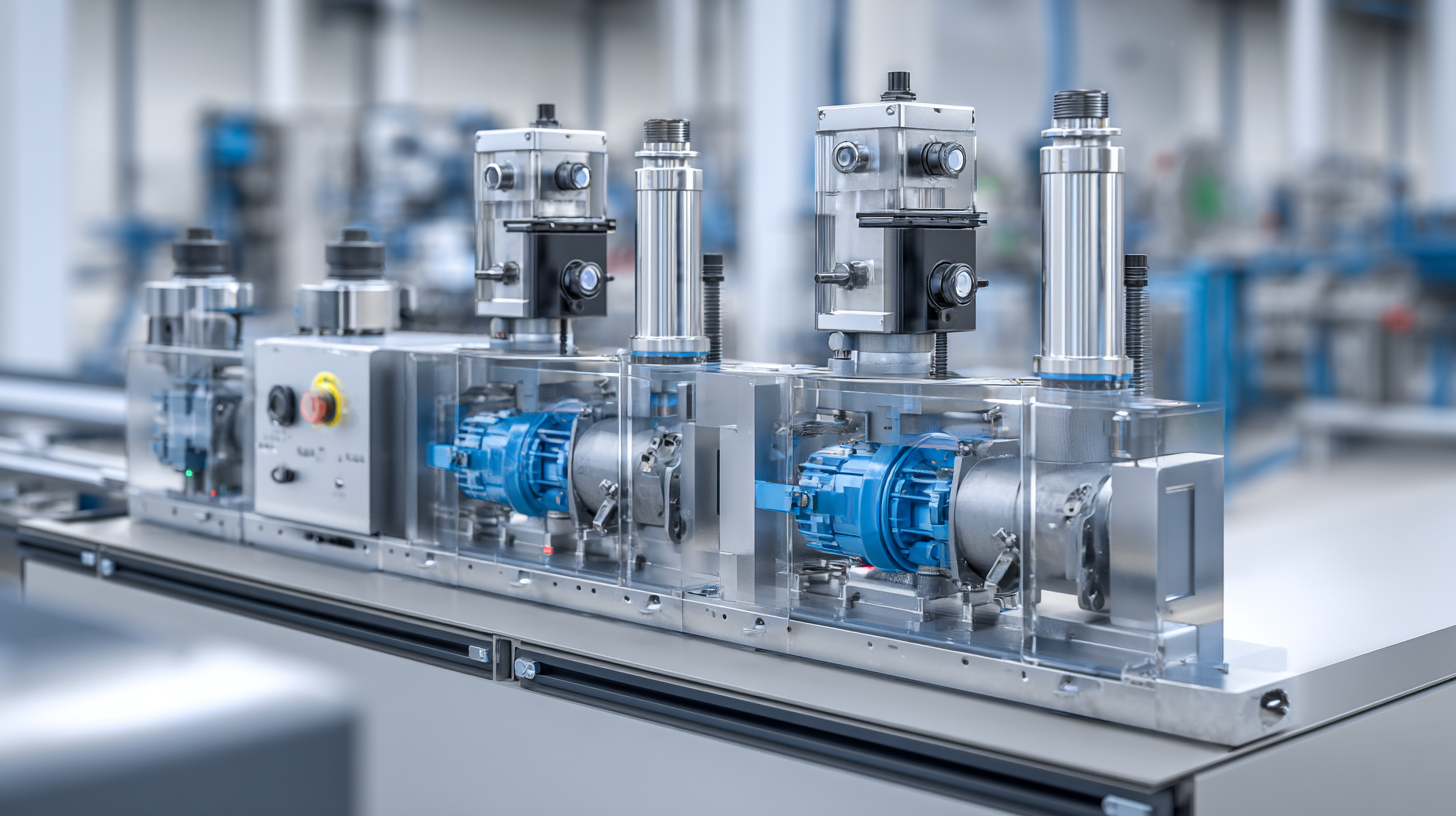

Metering pumps have become essential in modern industrial applications due to their precision and reliability in delivering exact chemical quantities. Unlike traditional pumping systems, which often rely on mechanical force and can be prone to inconsistency, metering pumps utilize advanced technology to ensure accurate flow rates. This level of control not only enhances efficiency but also minimizes waste, making them a sustainable choice for industries ranging from water treatment to pharmaceuticals.

Metering pumps have become essential in modern industrial applications due to their precision and reliability in delivering exact chemical quantities. Unlike traditional pumping systems, which often rely on mechanical force and can be prone to inconsistency, metering pumps utilize advanced technology to ensure accurate flow rates. This level of control not only enhances efficiency but also minimizes waste, making them a sustainable choice for industries ranging from water treatment to pharmaceuticals.

Tip: When selecting a metering pump, consider the specific flow requirements and the chemical properties of the fluids being pumped. This will ensure optimal performance and longevity of the pump.

Another significant advantage of metering pumps is their adaptability to varying operational conditions. They can be easily adjusted to accommodate changes in pressure, flow rate, and the characteristics of the fluid being transferred. This is especially important in processes where precise dosing of chemicals is critical for quality control and safety.

Tip: Regular maintenance and calibration of metering pumps can prevent potential issues and enhance accuracy over time. It’s advisable to set a routine check-up schedule to keep the system functioning at its best.

Applications of Metering Pumps in Various Industries

Metering pumps play a crucial role in various industrial applications, providing precise control over the flow of fluids. In the chemical industry, for instance, metering pumps are utilized to deliver additives or reactants at specific rates, ensuring consistent product quality. According to a report by MarketsandMarkets, the global metering pump market is projected to reach USD 8.38 billion by 2025, indicating a growing reliance on these pumps across diverse sectors.

In the pharmaceutical industry, accurate dosing is critical to ensure patient safety and drug efficacy. Metering pumps are used to dispense active pharmaceutical ingredients (APIs) in precise quantities, which is vital during the formulation process. A study from the International Society for Pharmaceutical Engineering highlights that the demand for advanced metering technologies is increasing, with a significant rise in the adoption of automated systems that improve accuracy and reduce human error.

Water treatment facilities also benefit greatly from metering pumps, where they are employed to inject chemicals such as chlorine and coagulants into the water supply. The Water Environment Federation reported that the use of metering pumps in wastewater treatment not only optimizes chemical usage but also enhances the overall efficiency of the treatment process. These applications underscore the importance of metering pumps, demonstrating their versatility and critical role in modern industrial practices.

Challenges and Solutions in Metering Pump Technologies

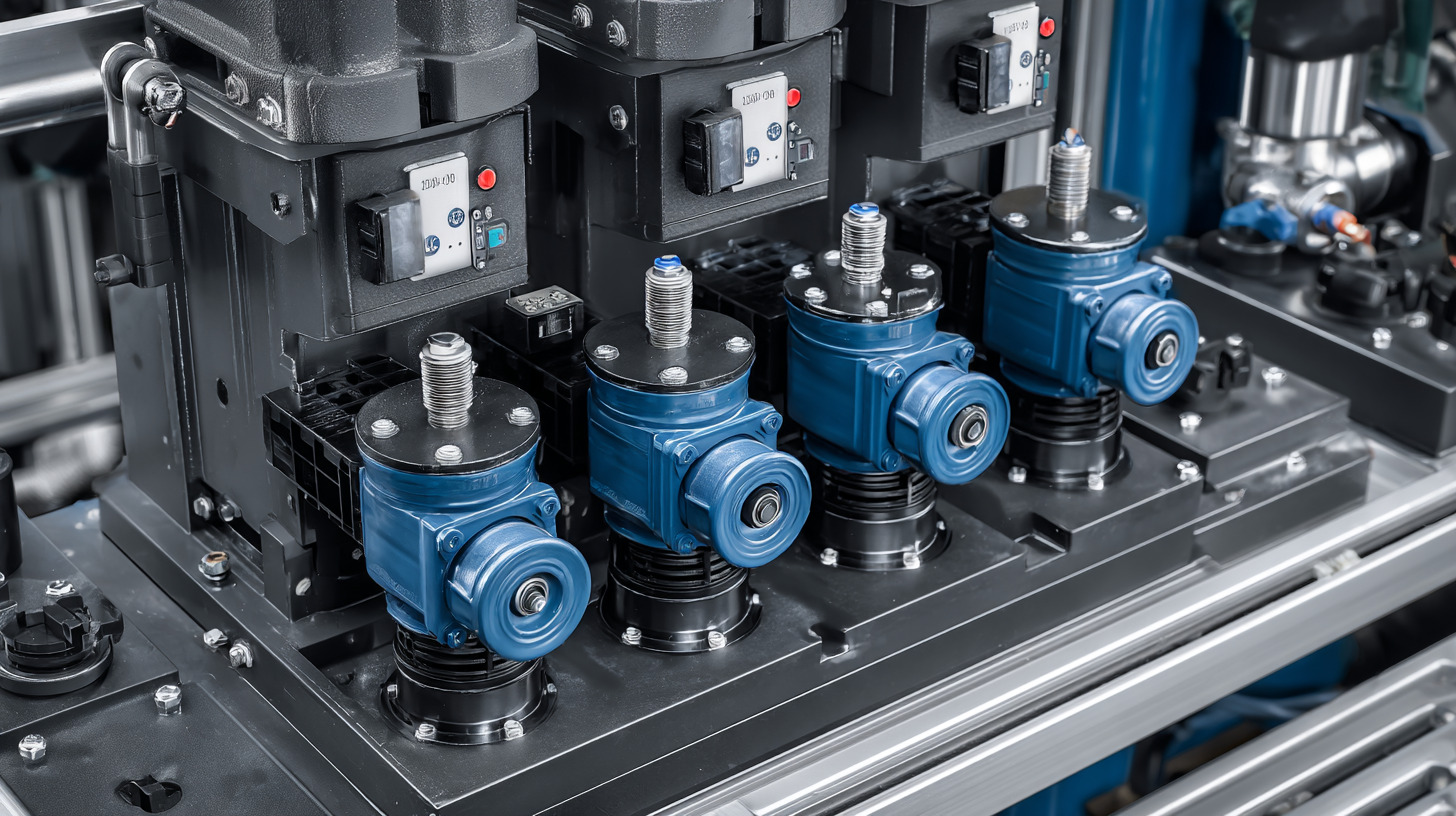

Metering pumps play a critical role in various industrial applications, but they face a set of unique challenges that must be addressed to ensure optimal performance. One of the primary challenges is achieving precise flow rates while maintaining the required chemical compatibility. Variability in fluid properties, such as viscosity and density, can significantly impact the accuracy of the metering process. Additionally, the need for real-time monitoring and control becomes paramount, as fluctuations in operating conditions can lead to over or under-dosing of critical substances.

To overcome these hurdles, advancements in metering pump technologies are essential. Manufacturers are increasingly investing in smart technology solutions that integrate sensors and automated control systems. These innovations enhance the reliability and accuracy of metering pumps by allowing for adaptive adjustments based on real-time data. Furthermore, the development of more resistant materials is crucial for extending the lifespan of metering pumps, particularly in corrosive or abrasive environments. By addressing these challenges through technology and design improvements, the efficacy and efficiency of metering pumps in industrial applications can be significantly enhanced.

Understanding the Importance of Metering Pumps in Modern Industrial Applications

The metering pump chart illustrates the distribution of metering pump usage across various industrial applications. Chemical processing and oil & gas industries are predominant users, reflecting the critical role of metering pumps in accurately delivering fluids and maintaining process efficiency.

Future Trends in Metering Pump Development and Innovation

The evolution of metering pumps is poised to significantly impact various industrial sectors, particularly in the realm of sustainability and precision dosing. As market dynamics shift towards automation and efficiency, the metering pump segment is expected to grow from USD 6.9 billion in 2025 to USD 11.2 billion by 2035, reflecting a compound annual growth rate (CAGR) of 4.9%. This growth is driven by innovations in pump design that cater to the increasing demand for accurate fluid control across diverse applications, from water treatment to chemical processing.

Future trends in metering pump technology are leaning toward enhanced automation and integration with advanced control systems. The incorporation of microfluidic technology, akin to what has been seen in the healthcare sector, is anticipated to create more efficient and compact metering solutions. As industries embrace a circular economy, the importance of efficient dosing is becoming even more critical, leading to innovations that reduce waste and improve resource utilization. This focus on sustainability, alongside advancements in performance and reliability, underscores the vital role of metering pumps in the industrial landscape of the future.

Understanding the Importance of Metering Pumps in Modern Industrial Applications - Future Trends in Metering Pump Development and Innovation

| Application Sector | Common Fluid Types | Pump Type | Flow Rate Range (L/h) | Future Trends |

|---|---|---|---|---|

| Chemical Processing | Acids, Bases, Solvents | Diaphragm Pump | 10 - 500 | Smart Monitoring Systems |

| Water Treatment | Sodium Hypochlorite, Polymeric Coagulants | Gear Pump | 50 - 1500 | Integration with IoT |

| Pharmaceuticals | Active Pharmaceutical Ingredients (APIs) | Peristaltic Pump | 1 - 300 | Advanced Material Usage |

| Food & Beverage | Sugars, Syrups, Flavors | Diaphragm Pump | 20 - 800 | Hygienic Design Innovations |

| Oil & Gas | Crude Oil, Lubricants | Progressive Cavity Pump | 100 - 3000 | Automation and Remote Control |

Related Posts

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

Maximizing Efficiency: How Chemical Feed Pumps Improve Industrial Process Control

-

Understanding the Benefits of Chemical Metering Pumps in Modern Water Treatment Systems

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

5 Best Practices for Choosing the Right Chemical Feed Pump