Blog

2025 Guide to Choosing the Best Chemical Injection Pumps for Your Needs

In the ever-evolving landscape of industrial operations, the selection of the right chemical injection pumps stands as a critical decision for businesses striving to achieve operational efficiency and safety. As noted by industry expert Dr. Emily Carter, a leading authority in fluid dynamics, "Choosing the right chemical injection pump is not just about performance; it’s about finding a solution that fits your specific operational needs." With the increasing complexity of industrial processes and stringent regulatory requirements, understanding the various options available is paramount.

This guide aims to equip you with the essential insights needed to navigate the diverse range of chemical injection pumps on the market. With an array of factors ranging from pump types and materials to application-specific requirements, making an informed choice can significantly impact your overall process efficiency and reliability. Whether you're looking to enhance your existing systems or diving into your first purchase, this guide will provide clarity on the best practices for selecting chemical injection pumps tailored to your operational demands.

Understanding Chemical Injection Pumps: Types and Applications

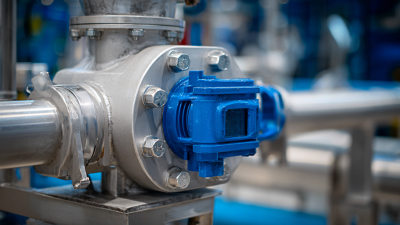

Chemical injection pumps play a crucial role in various industries, including

agriculture, water treatment, and chemical processing. Understanding the different types and applications of

these pumps is essential for making an informed choice. The metering pumps market, for

instance, is expected to reach USD 9.1 billion by 2030, reflecting the growing demand for

precise chemical dosing solutions. Within this segment, pumps that offer specific functions, such as accurate

flow rates and durable construction, are becoming increasingly vital for businesses aiming to enhance

operational efficiency.

In agriculture, selecting the right chemical injection pump can significantly impact irrigation systems and

crop yield. A step-by-step guide to choosing an irrigation pump outlines critical factors such as

pump types, required flow rates, and maintenance needs. With the chemical dosing

equipment market projected to grow from USD 2.0 billion in 2025 to

USD 3.2 billion by 2035, this sector highlights the importance of investing in reliable

pumps to ensure effective chemical management. Proper understanding and selection of these pumps not only optimize performance

but also promote sustainable practices in farming and other applications.

Key Factors to Consider When Selecting a Chemical Injection Pump

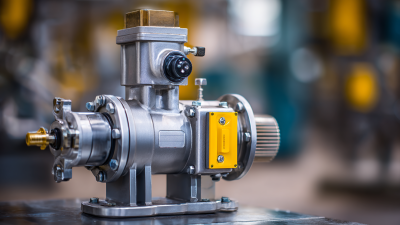

When selecting a chemical injection pump, several key factors must be carefully evaluated to ensure optimal performance for your specific application. First and foremost is the flow rate required for your operation. Understanding the precise volume of chemicals you need to inject will guide you toward models that fit your demands. The metering pumps market is projected to reach USD 9.1 billion by 2030, indicating a significant growth trend and a variety of options available. Depending on the complexity of your system, one must also consider the pump's compatibility with various chemical types, as some materials may cause degradation or corrosion over time.

Another crucial factor is the operational environment of the pump. High-pressure requirements and the need for reliable performance under varying temperatures can influence your selection. Additionally, maintenance considerations should not be overlooked; ease of service and the availability of spare parts can significantly impact long-term operational efficiency. By taking into account these factors and reviewing industry standards, such as detailed guides designed for specific applications, users can make informed decisions that will enhance their operational productivity and ensure sustainable chemical handling practices in their facilities.

2025 Guide to Choosing the Best Chemical Injection Pumps for Your Needs - Key Factors to Consider When Selecting a Chemical Injection Pump

| Parameter | Recommended Value | Considerations |

|---|---|---|

| Flow Rate | 0.5 - 100 GPH | Match with process requirements |

| Pressure Rating | Up to 3000 PSI | Assess system pressure demands |

| Chemical Compatibility | Material selection based on the fluid | Avoid corrosion and degradation |

| Power Source | Electric or pneumatic | Consider availability and safety |

| Control Options | Manual, automatic, or programmable | Match control to operational needs |

| Maintenance Requirements | Low, medium, or high | Plan for downtime and service intervals |

| Installation Type | Portable, skid-mounted, or inline | Assess space and mobility needs |

Top 5 Brands for Reliable Chemical Injection Pumps in 2025

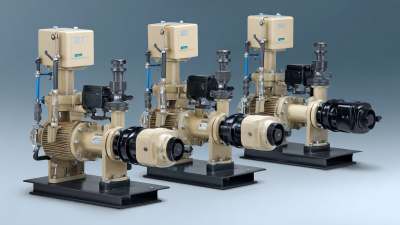

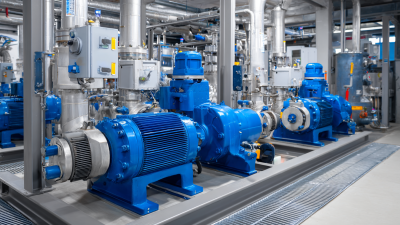

When looking to enhance your operations with chemical injection pumps in 2025, it's crucial to consider the industry's best brands that prioritize reliability and performance. The metering pumps market is anticipated to reach a significant valuation of $9.1 billion by 2030, highlighting an increasing demand for efficient chemical feeding solutions across various sectors. This growth reflects the necessity for accurate and consistent dosing in agriculture, water treatment, and the oil and gas industries.

Among the leading brands making waves in the chemical injection pump space this year are those that have consistently demonstrated their ability to provide innovative and robust pumping solutions. These manufacturers focus on reliability and user-friendly designs, ensuring their products meet the diverse needs of their customers. Investing in a high-quality chemical injection pump not only enhances operational efficiency but also aligns with the rising trend towards sustainability and precision in industrial processes, as highlighted by recent industry analyses.

Maintenance Tips to Ensure Longevity of Your Chemical Injection Pump

To ensure the longevity of your chemical injection pump, regular maintenance is key. One crucial aspect is to keep the pump clean and free from any chemical buildup. This can be achieved by routinely flushing the system with a compatible cleaning agent designed for the specific chemicals being pumped. Implementing a strict cleaning schedule based on usage frequency will help prevent corrosion and extend the life of critical components.

Another important maintenance tip is to regularly inspect and replace seals and diaphragms. These components often wear out due to continuous exposure to harsh chemicals and pressures. Establishing a timeline for inspections can help you catch wear and tear before it leads to significant performance issues or pump failures. Additionally, monitoring the pump's operational parameters, such as pressure and flow rate, allows for early detection of irregularities, facilitating timely interventions that can prevent costly downtimes and repairs.

Cost Considerations: Budgeting for Your Chemical Injection Pump Needs

When budgeting for a chemical injection pump, it's crucial to consider both the initial investment and ongoing operational costs. According to a report by Global Market Insights, the chemical injection pump market is projected to reach USD 4.8 billion by 2025, highlighting the growing importance of these systems in various industries. The purchase price of chemical injection pumps typically ranges from $2,000 to $10,000, depending on the pump's specifications and capabilities. However, it's essential to factor in additional costs such as installation, maintenance, and the operational expenses associated with the chemicals being injected.

Operational costs can significantly impact your overall budget. A study by Research and Markets indicated that maintenance can account for nearly 20% of total pump lifecycle costs. Therefore, selecting a reliable pump with lower maintenance requirements can lead to long-term savings. Additionally, consider the pump’s efficiency in terms of energy consumption, as more efficient models can reduce electricity costs over time. Understanding the total cost of ownership will help ensure that you allocate enough resources to meet your chemical injection needs effectively while optimizing your budget.

2025 Guide to Choosing the Best Chemical Injection Pumps for Your Needs

This chart presents an overview of the cost considerations for various chemical injection pump models in 2025. Consider these costs when budgeting for your chemical injection pump needs.

Related Posts

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

10 Unique Metering Pump Types You Should Know About

-

7 Essential Tips for Choosing the Right Chemical Injection Pumps

-

Understanding the Role of Chemical Feed Pumps in Modern Industrial Applications

-

Understanding the Benefits of Chemical Metering Pumps in Modern Water Treatment Systems