Blog

Exploring the Future: 2025 Top Pump Systems and Their Digital Innovations

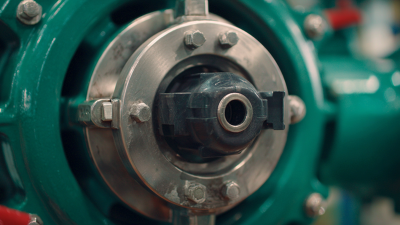

In the rapidly evolving landscape of industrial technology, pump systems stand at the forefront of innovation, particularly as we approach 2025. The integration of digital solutions into pump systems is reshaping how industries manage fluid transfer processes, enhance efficiency, and reduce operational costs. From smart sensors that provide real-time data on performance metrics to predictive analytics that enable proactive maintenance, the future of pump systems is increasingly intertwined with advancements in digital technology.

As companies seek to optimize their processes and embrace automation, understanding the latest trends and innovations in pump systems becomes essential. This exploration will highlight key technological breakthroughs, from IoT-enabled devices to software-driven monitoring systems, which are revolutionizing the functionality and reliability of pump operations. Additionally, insightful tips will be provided to help industry professionals navigate these developments, ensuring they are well-equipped to leverage digital tools to maximize efficiency and sustainability in their respective fields.

In this article, we will uncover the top pump systems set to dominate the market by 2025 and the digital innovations driving their evolution. By understanding these dynamics, stakeholders will be better positioned to make informed decisions and implement strategies that not only enhance their operational capabilities but also align with the future demands of a tech-centric industrial landscape.

Future Trends in Pump System Design for 2025

As we approach 2025, the pump systems industry is poised for significant transformation, driven by digital innovations and evolving market demands. The global market for high-pressure plunger pumps is expected to grow at a steady compound annual growth rate of 3.4%, reaching an estimated $1.217 billion by 2033. This growth reflects the increasing need for efficient machinery across various sectors, especially in China, where the general machinery industry is expanding due to infrastructure advancements and environmental initiatives.

**Tips for Future Pump System Designs:**

1. **Embrace Digitalization:** Leveraging AI and IoT technologies can enhance operational efficiency and predictive maintenance, reducing downtime and service costs.

2. **Focus on Customization:** As industrial needs become more specific, the ability to offer tailored solutions will set companies apart in a competitive market.

Innovative strategies in pump technology, such as the integration of permanent magnet technology, are redefining industry standards. With the shift towards sustainability, companies are also exploring green technologies to minimize environmental impacts. The focus is not just on market growth, but on creating intelligent systems that meet the demands of modern manufacturing and energy efficiency.

Exploring the Future: 2025 Top Pump Systems and Their Digital Innovations

This chart illustrates the anticipated trends in pump system design for 2025, focusing on key innovations such as energy efficiency, digital monitoring, predictive maintenance, remote control capabilities, and the use of green materials. Each trend reflects the industry's movement towards more sustainable and technologically advanced pump systems.

The Role of IoT in Revolutionizing Pump Systems

The integration of IoT into pump systems is set to revolutionize the industry, enhancing both operational efficiency and sustainability. According to the latest projections, the North America HVAC distribution market is anticipated to grow significantly, reaching an estimated USD 65.93 billion by 2024, with a CAGR of 6.2% from 2025 to 2030. This growth reflects the increasing demand for smart HVACR systems that incorporate AI and IoT technologies. These innovations empower remote monitoring, diagnostics, and energy optimization, thus significantly improving the performance of pump systems.

In the oil and gas sector, IoT applications are transforming traditional operations through real-time monitoring and predictive maintenance. This integration not only enhances operational efficiency but also contributes to lowering environmental impact, aligning with global sustainability goals. Moreover, the trend of digitizing industrial pump systems—from passive to smart technologies—underscores a shift towards more connected, responsive, and environmentally conscious practices. As the emphasis on digital innovations continues to grow, it is clear that IoT is playing a pivotal role in shaping the future of pump systems, leading to cost savings and enhanced performance across multiple industries.

Integrating AI for Predictive Maintenance in Pump Technologies

As we move toward 2025, the integration of artificial intelligence (AI) into pump technologies is set to revolutionize the way industries approach maintenance and operational efficiency. According to a recent report from MarketsandMarkets, the predictive maintenance market is projected to grow from $4.5 billion in 2020 to $12.3 billion by 2025, highlighting an increasing reliance on AI-driven solutions. By implementing machine learning algorithms and data analytics, pump systems can now predict failures before they occur, significantly reducing downtime and maintenance costs.

AI's capability to analyze vast amounts of operational data in real time allows for enhanced decision-making and proactive maintenance strategies. For example, sensors embedded in pump systems continuously monitor parameters like temperature, vibration, and flow rate. When these metrics deviate from established norms, AI algorithms can promptly identify potential issues, enabling technicians to address them before they escalate into costly breakdowns. This shift not only improves system reliability but also extends the lifespan of pump infrastructure, offering a sustainable path forward for industries reliant on these crucial systems.

Sustainability and Eco-Friendly Innovations in Pump Solutions

The increasing focus on sustainability and eco-friendly innovations in pump solutions is reshaping the industry landscape. As global water scarcity intensifies, advanced pump technologies are becoming indispensable for enhancing water security. For instance, the use of energy-efficient designs and smart technologies allows for significant reductions in energy consumption and operational costs, with reports indicating that modernized pumping systems can save up to 40% in energy use compared to traditional models.

Industry leaders are leveraging innovative practices to address wastewater management challenges. The adoption of dosing pump technologies not only optimizes chemical usage but also reduces environmental impact. According to recent studies, integrating smart pump systems with IoT capabilities can lead to enhanced monitoring and control, resulting in more sustainable water management practices. As highlighted by industry experts, the role of pumps in achieving energy efficiency and promoting sustainable resource use is crucial, marking them as essential contributors to future climate solutions. The ongoing innovations in pump technology signal a transformative shift towards more responsible and resilient water management systems globally.

Cybersecurity Challenges in Digitized Pump System Operations

As digital innovations rapidly transform pump systems, cybersecurity has emerged as a critical concern. The integration of

IoT (Internet of Things) technologies in pump operations enhances efficiency but also introduces vulnerabilities. These systems can be susceptible to

cyberattacks, potentially disrupting operations and causing significant financial losses. In 2025, as pump systems become increasingly interconnected, businesses must prioritize

robust cybersecurity measures to safeguard their operations against evolving threats.

Moreover, the rise in cyber threats necessitates a proactive approach to security within digitized pump systems. Companies should adopt advanced cybersecurity frameworks that include regular system updates, employee training on security protocols, and comprehensive incident response plans. By fostering a culture of security awareness and investing in cutting-edge protection technologies, businesses can mitigate risks associated with cyber vulnerabilities. Ultimately, addressing these cybersecurity challenges is essential for harnessing the full potential of digital pump system innovations while ensuring the reliability and integrity of operations.

Related Posts

-

5 Essential Tips for Choosing the Right Commercial Pump for Your Business Needs

-

Ultimate Guide to Choosing the Right Chemical Mixer: Key Features and Industry Insights

-

5 Essential Benefits of Using a Chemical Mixer for Your Manufacturing Process

-

7 Essential Tips for Choosing the Right Chemical Mixer for Your Industry Needs

-

Understanding the Mechanics of Diaphragm Pumps: The Key to Efficient Fluid Transfer

-

How to Choose the Right Types of Pumps for Your Industrial Needs: A Comprehensive Guide