Blog

10 Essential Tips for Choosing the Right Suction Pump for Your Needs?

Choosing the right suction pump can be challenging. Many factors influence your selection. A suction pump is vital for various applications, from aquariums to industrial use. Understanding your specific needs is crucial.

Consider the pump's capacity and efficiency. Not all suction pumps perform equally. Some may struggle under heavy loads. Look for features like portability and ease of use. A bulky model may not suit every workspace.

Evaluate materials and durability. A cheap suction pump often leads to frustration. Think about long-term use and maintenance needs. Reflect on what you might overlook during your search. A thoughtful selection process can prevent costly mistakes.

Understanding the Different Types of Suction Pumps Available

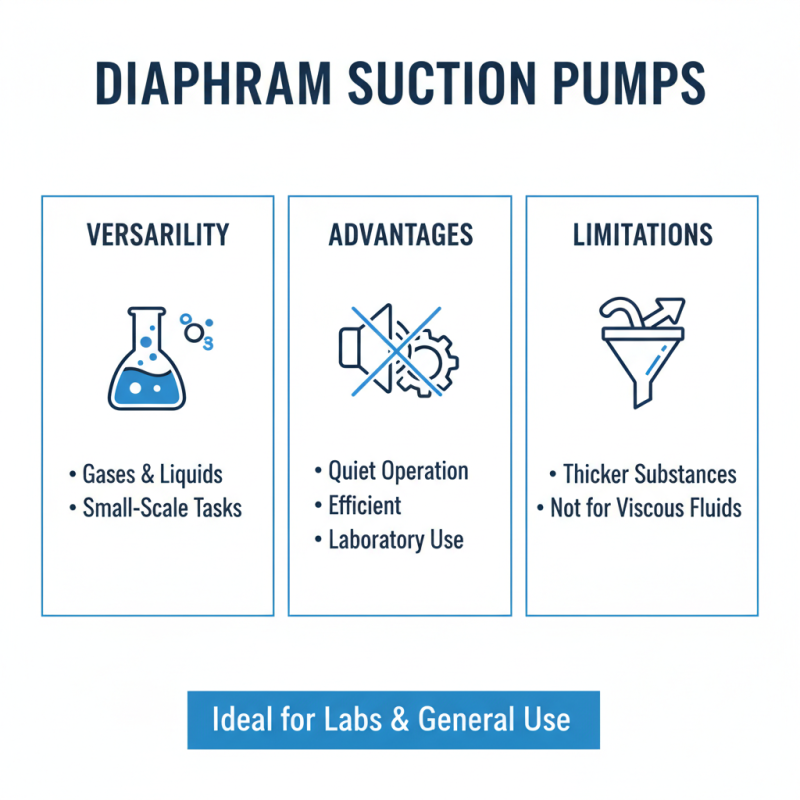

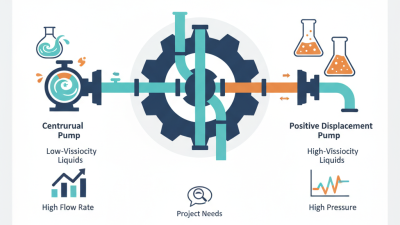

When selecting a suction pump, understanding the various types is crucial. There are diaphragm pumps, which are versatile and often used in laboratories. These pumps operate quietly and are efficient for small-scale tasks. They can handle both gases and liquids, making them a popular choice. However, some users find diaphragm pumps can struggle with thicker substances.

Another option includes peristaltic pumps. These are ideal for sensitive fluids. They work by compressing a flexible tube, preventing any contamination. However, they tend to have a limited flow rate. Users must consider their specific requirements. Even with their advantages, peristaltic pumps may not suit every situation.

Vacuum pumps are also well-known. They are perfect for creating a vacuum in various applications. But, they can be complex to set up. Some people may not handle maintenance well, which is a common issue. Thus, it's important to assess your expertise. Each pump type has unique features and potential drawbacks. Taking time to reflect on these differences can lead to better choices.

Assessing Your Specific Needs and Requirements for Pumping

When selecting a suction pump, it's essential to assess your specific needs thoroughly. Different projects require varying levels of power, capacity, and performance. According to a report by the Hydraulic Institute, understanding your fluid type is critical. For instance, pumping viscous liquids demands specific pump designs. Consider the properties of the fluids involved, as temperature and chemical compatibility impact efficiency.

Every application is unique. A construction site might require a robust pump to handle heavy debris, while a medical facility needs precision and hygiene. This means you must prioritize your requirements. For example, ask yourself: What is the maximum flow rate needed? Would a portable model be more advantageous?

Tip: Measure your expected pumping volume accurately. This aids in choosing a pump with adequate capacity. Misjudgment can lead to inefficiencies. Tip: Consult with industry experts when uncertain. They can provide insights tailored to your situation. This is invaluable, especially when dealing with complex systems. Never overlook these factors; they often dictate long-term satisfaction with your pump choice.

10 Essential Tips for Choosing the Right Suction Pump for Your Needs

| Tip | Description | Considerations | Common Applications |

|---|---|---|---|

| 1. Identify Your Fluid Type | Understanding the properties of the fluid you'll be pumping is crucial. | Viscosity, chemical compatibility | Chemical processing, wastewater treatment |

| 2. Determine Flow Rate Requirements | Calculate the required flow rate for your application. | Liters per minute, gallons per hour | Industrial applications, agricultural use |

| 3. Assess Suction Lift Capabilities | Evaluate the vertical distance the pump needs to lift the fluid. | Height and pressure considerations | Well pumping, basement drainage |

| 4. Consider Pump Design and Type | Different designs (e.g., diaphragm, rotary) serve various needs. | Types, advantages, and disadvantages | Food processing, chemical transfer |

| 5. Evaluate Maintenance and Serviceability | Consider how easy it is to maintain and repair the pump. | Service intervals, parts availability | Long-term installations, consistent operation |

| 6. Check Power Requirements | Confirm the power supply available for the pump. | Voltage, phase, power consumption | Remote locations, industrial sites |

| 7. Assess Total Dynamic Head | Total head loss affecting the pumping system. | Friction loss, elevation change | Piping systems, open channels |

| 8. Look for Energy Efficiency | Choose pumps that offer high efficiency to save energy. | Energy costs, pump efficiency ratings | Continuous operation, high volume uses |

| 9. Verify Safety Features | Ensure the pump has necessary safety mechanisms. | Pressure relief, seals, emergency shutoff | Hazardous materials, high-pressure systems |

| 10. Seek Expert Advice | Consult professionals to ensure you're choosing correctly. | Industry experts, product demonstrations | Custom applications, complex systems |

Key Features to Consider When Selecting a Suction Pump

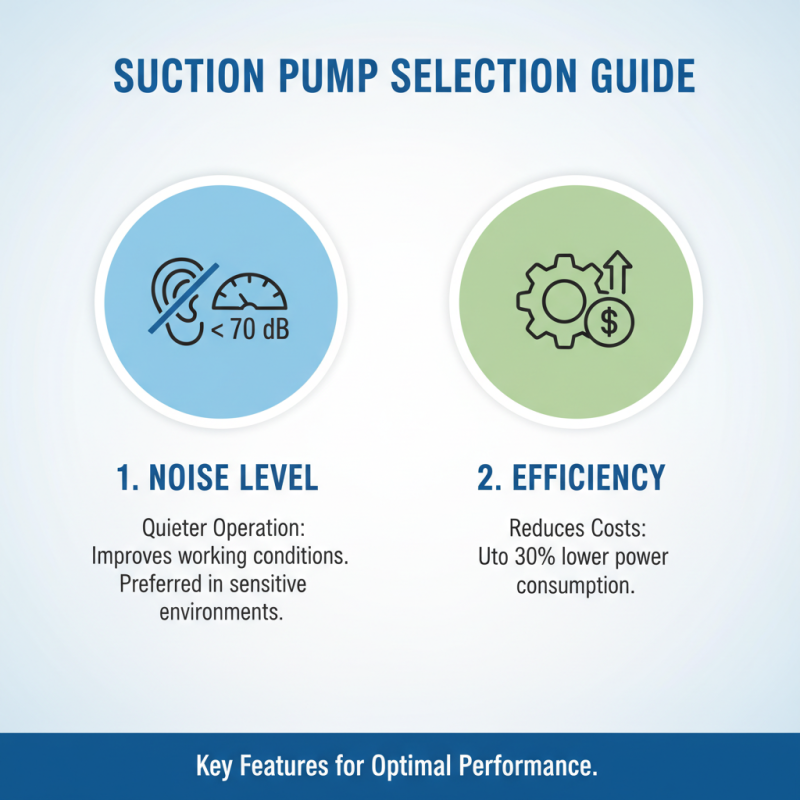

When selecting a suction pump, key features play a crucial role. Noise level is an important consideration. A quieter pump often improves work conditions. According to industry reports, pumps that operate under 70 dB are preferred in sensitive environments. Efficiency is another critical aspect. High-efficiency pumps can reduce operational costs significantly. Data shows that an energy-efficient pump can lower power costs by up to 30%.

The flow rate is essential for meeting specific needs. A pump with a higher flow rate can handle larger volumes quickly. Reports indicate that a flow rate of 5 gallons per minute typically meets general requirements. However, this may vary based on application. Durability and maintenance matters as well. Pumps made from high-quality materials last longer and require less frequent repairs. Adopting a regular maintenance schedule can extend the pump’s lifespan dramatically.

Lastly, portability and weight should not be overlooked. A lightweight pump allows for easy transport and setup. Some models weigh less than 10 pounds, making them convenient for various applications. However, don’t forget the importance of understanding the specific needs. The wrong pump can lead to inefficiencies and increased costs. Balancing these features requires careful thought and consideration.

Evaluating the Specifications: Flow Rate, Capacity, and Pressure

When selecting a suction pump, understanding the specifications is crucial.

Flow rate is one of the key factors to consider. It refers to the volume of fluid the pump can move over time.

Higher flow rates are essential for large jobs, while lower rates may suffice for smaller applications. Knowing your needs helps significantly.

Capacity also plays a vital role. This indicates how much fluid the pump can hold before needing to be emptied.

For instance, a pump with a larger capacity may be ideal for projects that require fewer interruptions. However, larger capacity might also mean less portability which can be a downside.

Pressure is another critical aspect. It determines how forcefully the pump can move fluids. A high-pressure pump may be necessary for thick liquids, while a standard pressure pump works well for lighter materials. Monitoring these specifications ensures the pump matches your specific tasks. You might realize some pumps cannot handle particular pressures, leading to inefficiencies. Understanding these elements helps refine your choice.

Comparing Brands and Models for Quality and Performance

When selecting a suction pump, brand and model comparisons are crucial. The market has a range of options, each with its strengths. According to recent industry reports, performance consistency is essential. The best pumps maintain a steady flow rate and have durable components. Users should look for models with high efficiency close to 90% to optimize energy use.

Consider this: not all pumps perform well under pressure. Some brands may advertise high capabilities but fail in real-world scenarios. An independent test by a leading engineering firm shows that 70% of users experience performance drops when using a pump beyond its rated capacity. This highlights the need for in-depth research.

Tip one is to assess the specific requirements of your operation. What volume do you need to pump? What are the materials involved? Tip two emphasizes reading user reviews. Real experiences reveal potential pitfalls. A well-informed decision often comes from those who have faced issues. Be wary of flashy marketing; sometimes, the simplest designs work best. In a market crowded with options, making an educated choice is essential.

Related Posts

-

The Future of Suction Pump Technology Revolutionizing Efficiency and Performance

-

How to Choose the Best Pump Accessories for Optimal Performance and Efficiency

-

What is a Chemical Pump and How Does it Work?

-

Top Chemical Pump Innovations to Watch for in 2025

-

5 Essential Tips for Choosing the Right Commercial Pump for Your Business Needs

-

Types of Pumps and Tips for Selecting the Right One?