Blog

Top 10 Essential Pump Accessories You Need for Optimal Performance?

In today’s fast-paced industrial world, using the right pump accessories can significantly impact efficiency. Many users overlook this critical aspect. They often don’t realize that these small components enhance performance. Quality accessories ensure that pumps operate smoothly and reliably.

Choosing the right pump accessories involves understanding your specific needs. For instance, a simple valve can prevent leaks and optimize flow. Yet, not all options suit every pump type. Users may need guides to select compatible attachments.

Reflect on the accessories you currently use. Are they truly making a difference? Investing in top-quality parts can save both time and money. Ultimately, having the right pump accessories can transform your operational effectiveness. Consider these factors carefully as you strive for optimal performance.

Essential Pump Accessories for Enhanced Efficiency

Efficient pump performance often hinges on the right accessories. Studies show that using proper fittings can boost efficiency by up to 30%. A quality strainer prevents debris accumulation, saving maintenance costs. This simple addition improves flow and extends pump life.

Hoses and connectors are equally crucial. Flexible hoses prevent stress on fittings and maintain optimal flow rates. Research has demonstrated that rigid connections can lead to a 15% reduction in efficiency. Regular inspections are essential. Worn or damaged hoses can introduce uncertainty in performance, posing risks in various applications.

Seal kits protect the internal components of pumps. They enhance longevity and reduce leaks, which can account for significant energy loss. Nearly 25% of pumps experience performance decline due to inadequate sealing. Investing in the right accessories is not just about efficiency; it’s about long-term reliability. Each component plays a vital role in maintaining a pump's operational integrity. The goal is clear: maximize performance while minimizing downtime.

Understanding the Importance of Pump Accessories

Pump accessories play a crucial role in the overall performance of a pump system. They influence efficiency and durability. Selecting the right accessories can enhance functionality while reducing downtime. Common accessories include hoses, fittings, and gauges. Each serves a specific purpose, ensuring smooth operation.

Understanding the importance of these accessories is essential. For example, using improper hoses can lead to leaks. This not only wastes resources but also poses safety risks. Similarly, the right gauges help monitor conditions accurately. However, many operators overlook these details. Ignoring them can lead to performance inconsistencies and higher maintenance costs.

Moreover, regular inspections of pump accessories are necessary. Wear and tear can go unnoticed until it's too late. A frayed hose might seem minor, yet it can lead to larger failures. Keeping an inventory of essential parts can mitigate unexpected breakdowns. Ultimately, small details in pump accessories have a big impact. Neglecting them can compromise the entire system's efficiency.

Top Must-Have Accessories to Optimize Pump Performance

When optimizing pump performance, several essential accessories emerge as critical to enhancing efficiency and reliability. Data shows that nearly 30% of all pump failures result from inadequate accessories. Investing in the right tools can dramatically reduce downtime and maintenance costs.

One key component is the right strainer. A quality strainer prevents debris from entering the pump, which can cause wear and tear. Studies indicate that a well-maintained strainer can extend pump life by up to 25%. Additionally, vibration dampeners can significantly reduce mechanical stress on pumps, helping to avoid potentially costly repairs.

Another vital accessory is seals and gaskets. Keeping your pump sealed properly can prevent leaks and maintain optimal performance. Research estimates that improper sealing can lead to a 20% loss in efficiency. Using the right accessories is more than just following the basics; it’s about proactive measures to fine-tune your system for improved output.

Top 10 Essential Pump Accessories for Optimal Performance

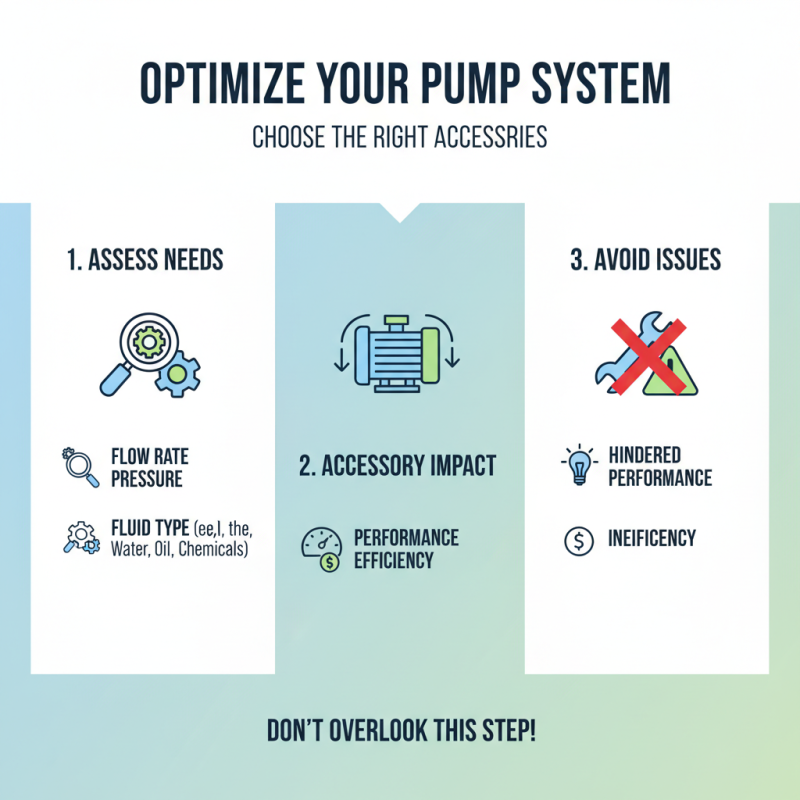

How to Select the Right Accessories for Your Pump System

Selecting the right accessories for your pump system is crucial. Many users overlook this step. The wrong accessory can hinder performance and lead to inefficiency. Start by assessing your specific needs. Consider factors like flow rate, pressure, and the type of fluid being pumped. Each accessory impacts performance differently.

For instance, a quality suction strainer can prevent debris from entering the pump. Without it, blockages may occur. Also, choose the right hoses and connectors. A mismatch can lead to leaks or reduced efficiency. Pay attention to the material; some fluids require specific types of hoses.

Maintenance accessories are often neglected. Regular inspection tools, replacement seals, and filters can save time and money in the long run. Reflect on your current setup. Are you using outdated components? Sometimes, investing in newer technologies yields better performance. Feel free to experiment, though mistakes will teach valuable lessons.

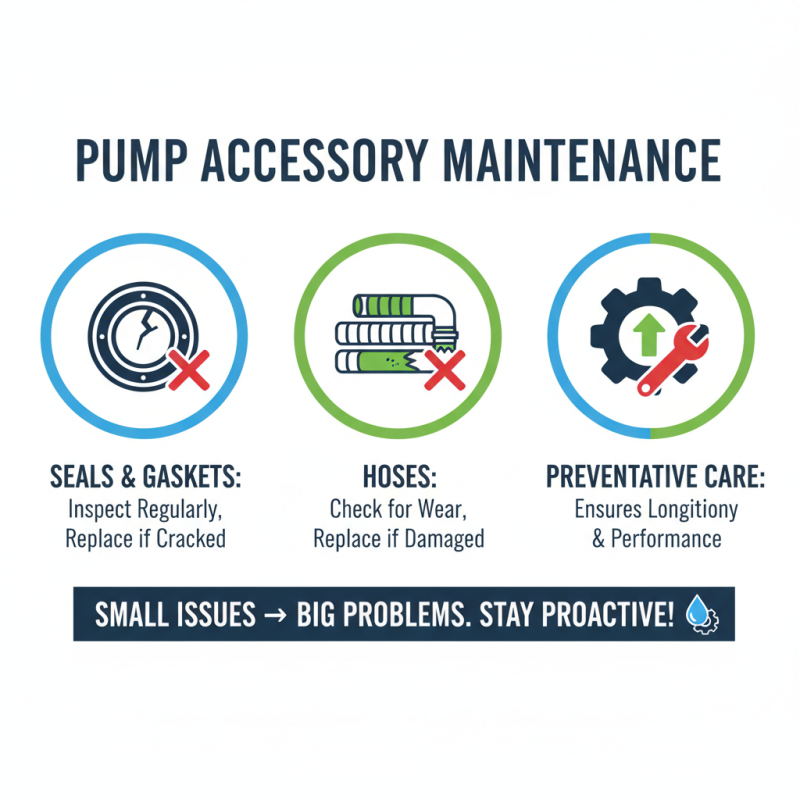

Maintenance Tips for Pump Accessories to Ensure Longevity

Maintaining pump accessories is crucial for their longevity and optimal performance. Regularly inspect seals and gaskets. Even a minor crack can lead to leaks, affecting efficiency. Keep an eye on hoses; replace them if you notice any signs of wear. Small issues can escalate quickly if left unchecked.

Clean filters regularly. Clogged filters restrict flow and strain the pump. Ensure that you're using the right filter type for your pump. It’s easy to overlook these details. Pay attention to the oil levels in gearboxes and bearings. Low oil can lead to overheating.

Don’t forget about the importance of proper storage. If accessories are not in use, store them in a dry, clean place. Dust and moisture can shorten their lifespan. Be proactive about repairs. Waiting too long can result in critical failures. Reflect on your maintenance routine. Small adjustments can lead to big improvements.

Related Posts

-

Harnessing Innovation in Pump Accessories at the 138th Canton Fair 2025 with Market Insights Driving Growth

-

How to Choose the Best Pump Accessories for Optimal Performance and Efficiency

-

2025 Top Metering Pump Innovations for Precision Fluid Control

-

How to Optimize Pump Technology for Increased Efficiency and Reduced Costs

-

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety

-

2025 How to Choose the Right Chemical Injection Pumps for Your Needs