Blog

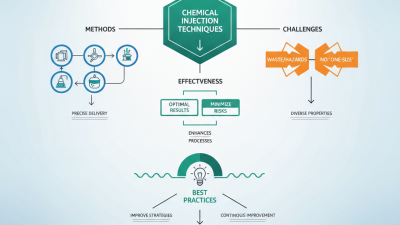

Why Chemical Injection is Essential for Efficient Industrial Processes?

Chemical injection plays a vital role in modern industrial processes. According to Dr. Emily Carter, a renowned expert in the chemical injection industry, “Chemical injection is a game-changer for productivity and efficiency.” This statement encapsulates the essence of why chemical injection is necessary.

In many industries, precise chemical dosing enhances product quality. For instance, chemical injection optimizes processes in oil and gas, water treatment, and manufacturing. However, there are challenges. Not all systems integrate this technology seamlessly. Inconsistent dosing can lead to inefficiencies and higher operational costs.

Reflection on these hurdles is crucial. Improving chemical injection techniques can further elevate industrial performance. As industries evolve, the demand for effective chemical injection solutions will only grow. This necessity highlights the importance of ongoing research and innovation in this crucial field.

Understanding Chemical Injection in Industrial Processes

Chemical injection plays a pivotal role in various industrial processes. It involves the precise addition of chemicals to enhance efficiency and ensure safety. This method is particularly vital in sectors like oil and gas, water treatment, and food production. According to a report from the International Energy Agency, chemical injection in oil extraction can boost production rates by up to 30%. This statistic highlights the technology's importance in resource management.

Different chemicals serve distinct purposes. For instance, corrosion inhibitors protect equipment and extend its lifespan. Flotation agents enhance separation processes during mineral processing. However, the choice of chemicals must be carefully assessed. Improper injection can lead to contamination and affect product quality. The industry struggles with balancing efficiency and environmental impact. Reports indicate that over 20% of chemical usage in some sectors doesn't yield significant results. This inefficiency calls for a reevaluation of methods.

Additionally, the cost associated with chemical injection should not be overlooked. Operational expenses may rise if the chemicals used are not optimal. The manufacturing sector has seen instances where improper management leads to lost revenue. Experts advocate for more integrative approaches, integrating data analytics to fine-tune chemical usage. As the industry evolves, there's a continuing need for reflection and improvement in chemical injection practices.

The Role of Chemical Injection in Enhancing Process Efficiency

Chemical injection is a crucial component in many industrial processes. It facilitates the precise addition of chemicals in controlled amounts. This ensures optimal conditions for various reactions and operations. According to a report by the International Society for Automation, effective chemical injection can improve process efficiency by up to 30%. This significant enhancement can lead to reduced operational costs.

In chemical manufacturing, injection systems maintain consistency and quality. These systems help adjust parameters like pH and temperature in real-time. The accuracy of chemical injection prevents waste and improves yield. Studies show that improper injection can lead to a 15% drop in product quality. Therefore, monitoring and adjusting injection rates are vital.

However, not all chemical injection setups work flawlessly. Issues like clogging or incorrect dosing can arise. In fact, nearly 20% of injection systems fail to meet performance expectations. Regular maintenance and calibration are essential to overcome these challenges. Addressing these imperfections can lead to better efficiency and reliability in industrial processes.

Types of Chemicals Commonly Injected in Industrial Settings

In industrial settings, chemical injection serves many functions. Various types of chemicals are commonly used. These include biocides, which control microbial growth in water systems. Corrosion inhibitors are also important. They protect metal surfaces from degradation. This is vital in extending equipment life and reducing maintenance costs.

Another common type is flocculants. These help in water treatment by clumping particles together for easier removal. Many industries rely on these agents for effective filtration. Additionally, pH adjusters are crucial. They maintain optimal acidity levels for various processes. The right balance can prevent equipment damage and ensure product quality.

Mistakes can happen with chemical injection. Miscalculations in dosage can lead to inefficiencies. It may also result in unexpected chemical reactions. Understanding the specific needs of each process is essential. Regular monitoring is necessary to optimize chemical use. Proper training for personnel can minimize risks. Assessing the effectiveness of the chemical choices is vital for long-term success.

Benefits of Automated Chemical Injection Systems

Automated chemical injection systems revolutionize industrial operations. They ensure precise dosing, improving overall efficiency. These systems operate with minimal human intervention, reducing labor costs and errors. With reliable technology, businesses can maintain consistent production quality. Moreover, automation facilitates better compliance with safety regulations.

Tips: Regularly calibrate your system to maintain accuracy. Small discrepancies can lead to significant production issues.

These systems also support real-time monitoring. This capability allows for quick adjustments, enhancing responsiveness in dynamic environments. Each ingredient is monitored, ensuring optimal chemical use. It’s essential to analyze these metrics periodically. Overlooking performance data could lead to wasted resources and potential downtime.

Tips: Train staff on troubleshooting techniques. Even the best systems may encounter hiccups. A knowledgeable team can quickly resolve issues and keep processes running smoothly.

Safety and Compliance Considerations in Chemical Injection Practices

In industrial settings, safety is paramount. Chemical injection poses significant risks if not managed properly. According to the National Safety Council, approximately 4.6 million workers are exposed to hazardous substances annually. This clearly highlights the need for strict safety measures in chemical handling.

Compliance with regulations is another critical aspect. The Occupational Safety and Health Administration (OSHA) has established standards for chemical safety. Industries must adhere to these guidelines to avoid penalties. However, many companies fall short in training their staff. Reports show a lack of awareness about safety protocols among workers, leading to potential hazards. Regular training sessions and safety audits can bridge this gap.

A focus on personal protective equipment (PPE) also deserves attention. Compliance with PPE standards is crucial, yet often ignored. Data from the Bureau of Labor Statistics indicates that industrial chemical incidents frequently involve inadequate PPE. Companies must invest in appropriate gear and ensure its proper use. Addressing these issues can significantly reduce risks associated with chemical injection processes.

Related Posts

-

Innovative Chemical Injection Solutions at the 138th China Import and Export Fair 2025

-

2026 Best Chemical Injection Techniques for Effective Results?

-

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety

-

How to Choose the Right Diaphragm Chemical Metering Pump for Your Needs

-

Why Choose a Diaphragm Metering Pump for Your Liquid Transfer Needs

-

How to Choose the Right Chemical Metering Pump for Your Industry Needs