Blog

Why Choose a Diaphragm Metering Pump for Your Liquid Transfer Needs

In the world of liquid transfer applications, the choice of equipment can significantly impact efficiency and reliability. As stated by Dr. Emily Sanderson, an industry expert in fluid dynamics, "Diaphragm metering pumps combine precision with durability, making them an ideal solution for a variety of liquid transfer needs." This statement underscores the importance of selecting the right pumping technology for optimal performance.

Diaphragm metering pumps are designed to provide accurate and consistent flow rates, making them essential in industries ranging from pharmaceuticals to chemical processing. Their unique construction allows for safe handling of aggressive or viscous liquids, catering to diverse operational requirements. By offering precise dosing capabilities, diaphragm metering pumps enhance system reliability while minimizing waste, ultimately contributing to more efficient processes.

Choosing a diaphragm metering pump can lead businesses to not only meet regulatory compliance but also achieve cost savings through reduced downtime and waste. As the landscape of fluid transfer evolves, understanding the advantages of diaphragm metering pumps will remain crucial for professionals seeking effective solutions in their respective fields.

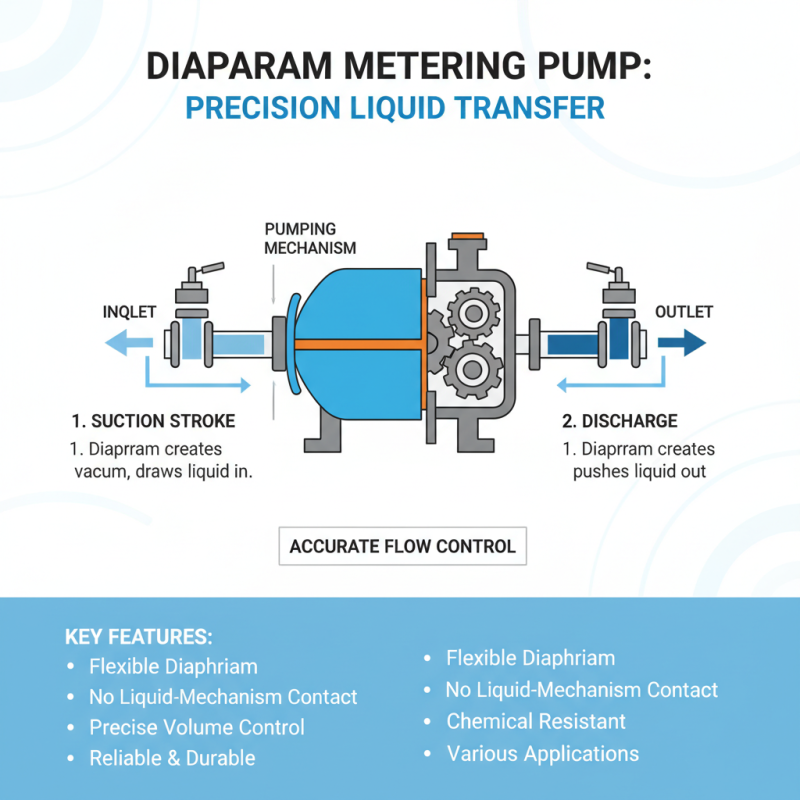

Understanding Diaphragm Metering Pumps and Their Mechanism

Diaphragm metering pumps are essential devices for precise liquid transfer, employing a unique mechanism that ensures accuracy and reliability. At their core, these pumps utilize a flexible diaphragm, which acts as a barrier between the liquid and the pumping mechanism. When the diaphragm is displaced, it creates a suction effect that draws liquid into the chamber and then expels it during the return stroke. This design allows for precise control over the flow rate, making diaphragm metering pumps ideal for applications requiring exact fluid measurements.

The operation of diaphragm metering pumps is characterized by their ability to handle various fluids, including corrosive and viscous liquids. The diaphragm is typically made from durable materials that withstand chemical reactions and wear, providing longevity and minimizing maintenance needs. Additionally, by isolating the pump mechanics from the liquid being transferred, diaphragm pumps greatly reduce the risk of contamination, a crucial factor in many industries such as pharmaceuticals and food processing. This mechanism also allows for dry running without damage, which is a significant advantage over other pumping technologies.

Advantages of Diaphragm Metering Pumps for Liquid Transfer

Diaphragm metering pumps are increasingly chosen for liquid transfer needs due to their unique advantages in precision and reliability. One major benefit is their ability to deliver accurate flow rates, which is crucial in applications where exact measurements are necessary. The diaphragm mechanism ensures that the flow is consistent and adjustable, allowing operators to fine-tune the pump settings to meet specific requirements. This precision not only enhances process efficiency but also minimizes waste, making it an environmentally friendly choice.

Another significant advantage is the diaphragm pump's inherent ability to handle a wide variety of liquids, including those that are corrosive or abrasive. The separation of the liquid from the mechanical components through the diaphragm means that the pump can work with harsh chemicals without compromising its integrity. Additionally, diaphragm metering pumps are less prone to leaks, offering enhanced safety in environments where chemical exposure must be minimized. With their versatile design and reliability, diaphragm metering pumps are often the preferred option for industries ranging from pharmaceuticals to food and beverage.

Applications of Diaphragm Metering Pumps Across Industries

Diaphragm metering pumps are increasingly recognized across various industries for their precision and reliability in liquid transfer applications. These pumps offer distinct advantages in sectors such as water treatment, pharmaceuticals, and food processing. According to a report by Grand View Research, the global diaphragm pump market is projected to reach $8.3 billion by 2027, indicating a robust growth trajectory as industries seek efficient solutions for precise fluid handling. In water treatment, for instance, diaphragm metering pumps excel in dosing chemicals such as chlorine and coagulants, ensuring consistent water quality and compliance with health standards.

In the pharmaceutical industry, where accuracy is paramount, diaphragm metering pumps are favored for their ability to handle corrosive and viscous liquids while providing tight control over flow rates. A study published in the Journal of Pharmaceutical Sciences highlighted that the accurate dosing of active pharmaceutical ingredients is crucial for drug efficacy and safety. The flexibility of diaphragm pumps allows for easy adjustments in flow rates, making them ideal for the dynamic requirements of pharmaceutical manufacturing.

Similarly, in food processing, these pumps help maintain hygiene and product quality by facilitating the transfer of ingredients without contamination, thus adhering to strict food safety regulations. Overall, the versatility and reliability of diaphragm metering pumps make them indispensable tools across various sectors, driving operational efficiency and compliance.

Factors to Consider When Choosing a Diaphragm Metering Pump

When selecting a diaphragm metering pump for your liquid transfer needs, several critical factors should be considered to ensure optimal performance and reliability. First, the type of liquid being transferred plays a fundamental role in pump selection. Different liquids exhibit varying viscosities, corrosiveness, and particle sizes, which can significantly influence how the pump operates. For example, if you're dealing with highly viscous fluids, a pump designed for thicker liquids will be necessary to maintain efficiency and prevent damage.

Another essential consideration is the flow rate and pressure requirements. It’s crucial to assess the specific flow rate needed for your application, as diaphragm metering pumps are available in various configurations to handle differing demands. Additionally, understanding the system pressure allows you to choose a pump that can deliver the necessary output without compromising performance.

Lastly, durability and maintenance characteristics should not be overlooked. Selecting a pump made from materials suitable for your application's environment, along with an easy-to-maintain design, will ensure longevity and reduce downtime in your operations.

Maintenance Tips for Optimal Performance of Diaphragm Pumps

Diaphragm metering pumps are essential for precise liquid transfer applications, offering reliability and accuracy. However, like any equipment, they require regular maintenance to ensure they operate at their best. Proper maintenance not only extends the life of the pump but also enhances its performance, making it crucial for operators to establish a routine.

One key maintenance tip is to regularly inspect the diaphragm for signs of wear or damage. A compromised diaphragm can lead to leaks and affect the pump's flow rate. Replacing the diaphragm as part of a scheduled maintenance plan can prevent costly downtime and ensure consistent performance. Additionally, keeping the pump clean and free from debris can facilitate smooth operation and reduce wear on moving parts.

Another important aspect is monitoring the pump's fluid levels and ensuring that they are within the recommended range. Low fluid levels can overheat the pump and cause failure, while excessive levels may lead to backpressure issues. Regularly checking and calibrating the pump settings according to the specific application will further enhance its efficiency, providing peace of mind while ensuring optimal performance in liquid transfer tasks.

Why Choose a Diaphragm Metering Pump for Your Liquid Transfer Needs - Maintenance Tips for Optimal Performance of Diaphragm Pumps

| Feature | Description | Maintenance Tips |

|---|---|---|

| Accuracy | Provides precise flow control for a variety of liquids. | Regularly calibrate the pump to maintain accuracy. |

| Versatility | Can handle different types of fluids, including corrosive and viscous liquids. | Use compatible materials to avoid corrosion. |

| Flow Rate | Offers a wide range of flow rates to suit different applications. | Monitor flow rates regularly and adjust settings as needed. |

| Ease of Maintenance | Simple design offers easy access for maintenance and repairs. | Conduct routine inspections and replace damaged parts promptly. |

| Energy Efficiency | Can operate at lower energy levels compared to other pump types. | Keep the pump clean and lubricated to enhance efficiency. |

Related Posts

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

Understanding the Importance of Diaphragm Metering Pumps in Precision Fluid Control

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

Innovative Chemical Injection Solutions at the 138th China Import and Export Fair 2025

-

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety