Blog

Top Tips for Choosing the Right Tank Mixer for Your Needs

Choosing the right tank mixer is essential for various applications. A tank mixer can enhance mixing efficiency, improve product consistency, and save time. However, selecting the perfect one can be challenging.

There are many factors to consider when choosing a tank mixer. You need to evaluate your specific needs, including the type of liquid you are mixing and its viscosity. The size of the tank also plays a crucial role. A mixer that works well in a small tank may not perform as effectively in a larger one.

It’s easy to overlook these details in the selection process. Some mixers might seem high-performing at first glance, but they may not suit your needs upon closer inspection. A well-considered choice can lead to significant improvements in productivity. However, it may take time and effort to find the right fit.

Understanding the Basics of Tank Mixers and Their Applications

When selecting a tank mixer, it is essential to understand how they function. Tank mixers help mix liquids for various applications, including food processing, chemical manufacturing, and wastewater treatment. These devices ensure that the components achieve a consistent mixture, which is vital for product quality. The type of tank mixer you choose will depend on the viscosity, volume, and mixing requirements of your application.

One tip is to assess your mixing needs carefully. Determine the liquid's viscosity. Thicker liquids require more powerful mixers. For instance, a gentle mixer suits a light liquid. However, a more robust option is necessary for thicker mixtures. Next, consider the tank size. A mixer must fit comfortably within the tank. Size matters. A too-small mixer won’t do a good job.

Another consideration is energy efficiency. Some mixers consume more energy than they need to. It's good to find an option that balances mixing performance and energy usage. Finally, reflect on maintenance. Mixers require upkeep, and neglect can lead to inefficiency. Regular checks can prolong its lifespan. Take time to weigh these factors. It’s a step that can save resources in the long run.

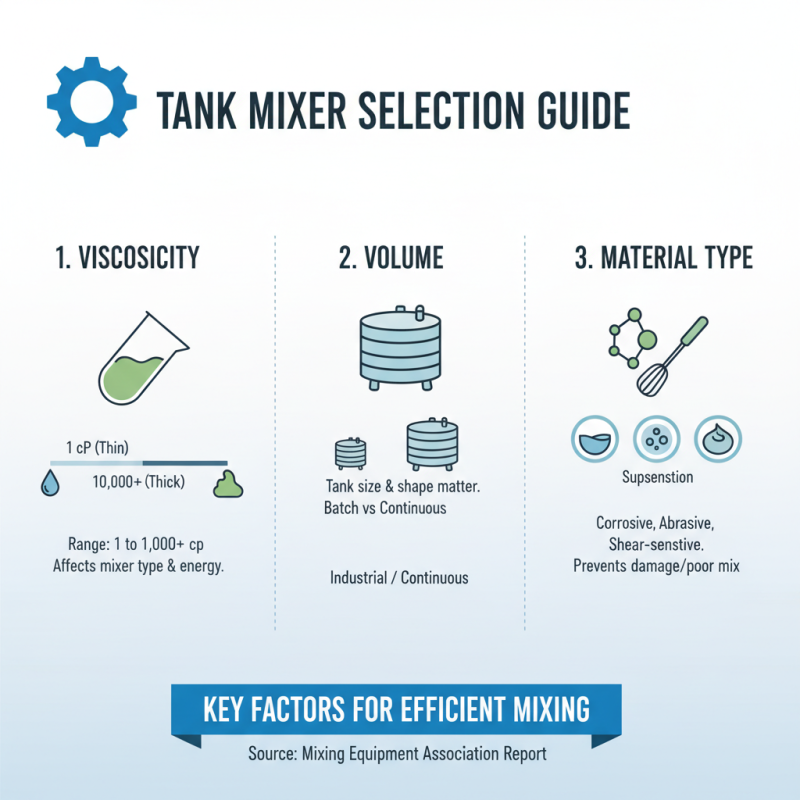

Identifying Your Mixing Needs: Viscosity, Volume, and Material Types

When selecting a tank mixer, understanding your mixing needs is crucial. Viscosity, volume, and material types significantly influence the mixer’s efficiency. According to a recent report by the Mixing Equipment Association, viscosity levels in industries often range from 1 to 10,000 cP. For instance, thin liquids like water require different mixers than thick pastes. This difference is essential in preventing inadequate mixing or excessive energy consumption.

Volume matters too. Many mixing applications have specific volume requirements. A report from the Chemical Engineering journal indicates that mixers for large-scale operations must accommodate volumes from hundreds to thousands of gallons. A mismatch can lead to inefficient processes and wasted resources. Furthermore, the material type plays a critical role. Mixing various materials, such as powders, slurries, or emulsions, requires specialized mixers with appropriate design features. Mixing metallic powders, for example, demands a different approach than blending liquid chemicals.

Identifying these factors early can avoid costly mistakes. Transitioning without understanding these variables can result in suboptimal operations. Investing time in evaluating viscosity, volume, and material types can ultimately lead to improved performance and productivity. Not all mixers are created equal, and this reality warrants careful consideration of specific needs.

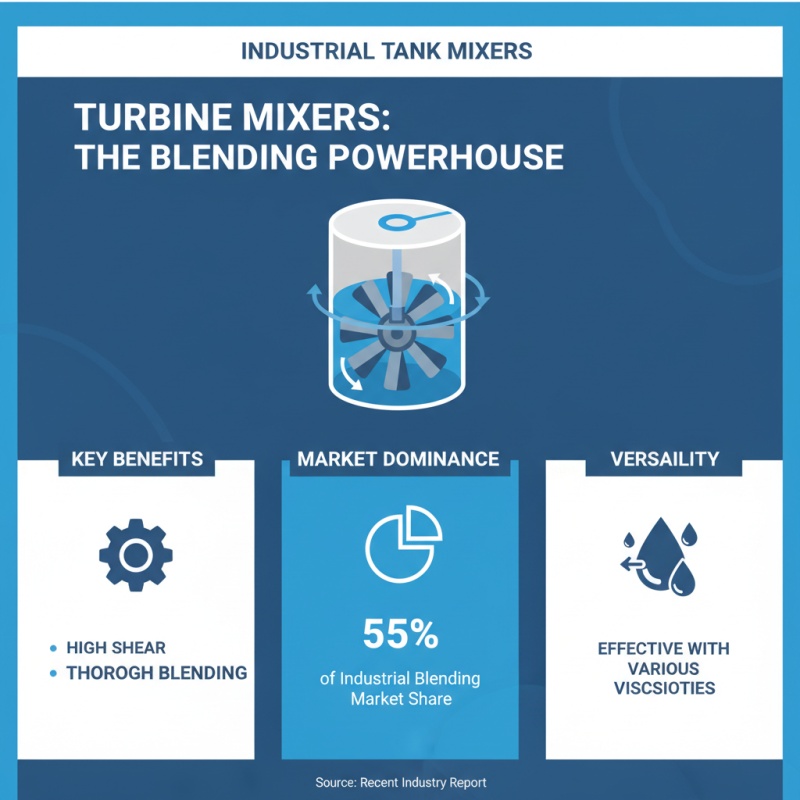

Assessing Mixer Types: Choosing Between Turbine, Propeller, and More

When choosing a tank mixer, understanding the types available is crucial. Turbine mixers are popular for their efficiency. They work well in applications requiring high shear and thorough blending. A recent report showed that turbine mixers account for 55% of the market share in industrial blending. Their design allows for effective mixing of various viscosities.

Propeller mixers, on the other hand, offer a gentler mixing action. They are ideal for delicate substances. These mixers cause less shear, making them suitable for applications in food and pharmaceutical industries. According to industry data, the use of propeller mixers is growing, especially in processes where preserving ingredient integrity is vital.

Tips for choosing the right type include assessing your specific mixing needs. Evaluate the viscosity and shear sensitivity of your materials. Additionally, consider the tank dimensions. Your mixer should provide adequate flow patterns across the vessel. Also, think about energy efficiency. Some mixers consume more power than others, adding to operational costs. Balancing performance with cost is essential for long-term success.

Evaluating Power Requirements and Energy Efficiency Considerations

When selecting a tank mixer, power requirements play a crucial role. The right mixer should match the viscosity of the fluids involved. According to recent reports, the energy consumption of industrial mixers can account for up to 40% of manufacturing energy costs. Therefore, assessing the power needs accurately is essential.

Energy efficiency should not be an afterthought. Many mixers operate at varying efficiencies based on design and motor type, which can affect operational costs significantly. Studies show that optimizing mixer designs can yield savings of 15-30% in energy use. However, innovations often come with a higher upfront cost, leading some companies to hesitate.

Design and application must work together. Mismatch between motor power and tank size can lead to inefficiencies. Underpowered mixers struggle with thick materials, while overpowered ones waste energy. This discrepancy raises questions about long-term investment. Regular assessments can help businesses adapt and refine their mixer choices over time, ensuring better performance and lower costs.

Maintenance and Durability: Key Factors in Selecting a Tank Mixer

When selecting a tank mixer, maintenance and durability are crucial factors. Many operators overlook these aspects, leading to costly downtime. According to a recent industry report, poor maintenance can increase operational costs by up to 30%. This highlight shows the importance of choosing a mixer that is easy to maintain and built to last.

Durability often correlates with the materials used in manufacturing. Mixers made from high-quality stainless steel resist corrosion better than those made from lower-grade materials. A study found that mixers with a life span of over 10 years typically show fewer breakdowns. Operators need to assess the components and design thoroughly. Sometimes, opting for cheaper models results in more repairs later. Such decisions may not seem critical at first but can lead to greater expenses over time.

Consider how operational environments affect mixer performance. For instance, mixers used in high-viscosity applications must withstand more wear and tear. As per industry guidelines, examining user feedback can provide insights into a mixer's long-term performance. Real user experiences often reveal important information that technical data cannot. These reflections can guide better decision-making when investing in a tank mixer.

Top Tips for Choosing the Right Tank Mixer for Your Needs

| Mixer Type | Application | Material | Maintenance Frequency | Durability Rating |

|---|---|---|---|---|

| Mechanical Mixer | Liquid Mixing | Stainless Steel | Monthly | High |

| Magnetic Drive Mixer | Chemicals | PTFE | Quarterly | Medium |

| Air Mixer | Suspension Mixing | Aluminum | Biannually | Low |

| Pumps Mixer | Slurries | Cast Iron | Annually | High |

Related Posts

-

Top 5 Tank Mixers to Boost Your Efficiency in 2025

-

Innovative Tank Mixer Applications Across Various Industries

-

How to Choose the Right Tank Mixer for Your Industrial Needs

-

2025 How to Choose the Right Tank Mixer for Your Industrial Needs

-

Essential Tank Mixer Guide: Mastering Mixing Techniques for Optimal Results

-

10 Unique Metering Pump Types You Should Know About