Blog

2025 How to Choose the Right Tank Mixer for Your Industrial Needs

In the ever-evolving landscape of industrial operations, the selection of the appropriate tank mixer is a crucial decision that can significantly impact both efficiency and product quality. According to a recent industry report by MarketsandMarkets, the global market for tank mixers is expected to reach $2.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.2%. This growth underscores the critical role that tank mixers play in a wide array of applications, including chemical processing, wastewater treatment, food and beverage manufacturing, and pharmaceuticals.

Choosing the right tank mixer requires a thorough understanding of several factors, including the characteristics of the fluids being processed, the specific mixing requirements, and the operational environment. For instance, different types of mixers—such as axial flow, radial flow, and static mixers—offer varying advantages depending on the viscosity and density of the materials involved. A well-considered choice can enhance mixing efficiency, reduce energy consumption, and ensure product consistency, ultimately contributing to a significant competitive edge in the market.

As industries continue to innovate and adapt to changing demands, the importance of selecting the correct tank mixer cannot be overstated. This decision not only affects operational performance but also influences the overall sustainability of industrial processes. In this context, understanding the latest trends, technologies, and best practices in tank mixer selection is essential for industrial stakeholders aiming to optimize their mixing processes.

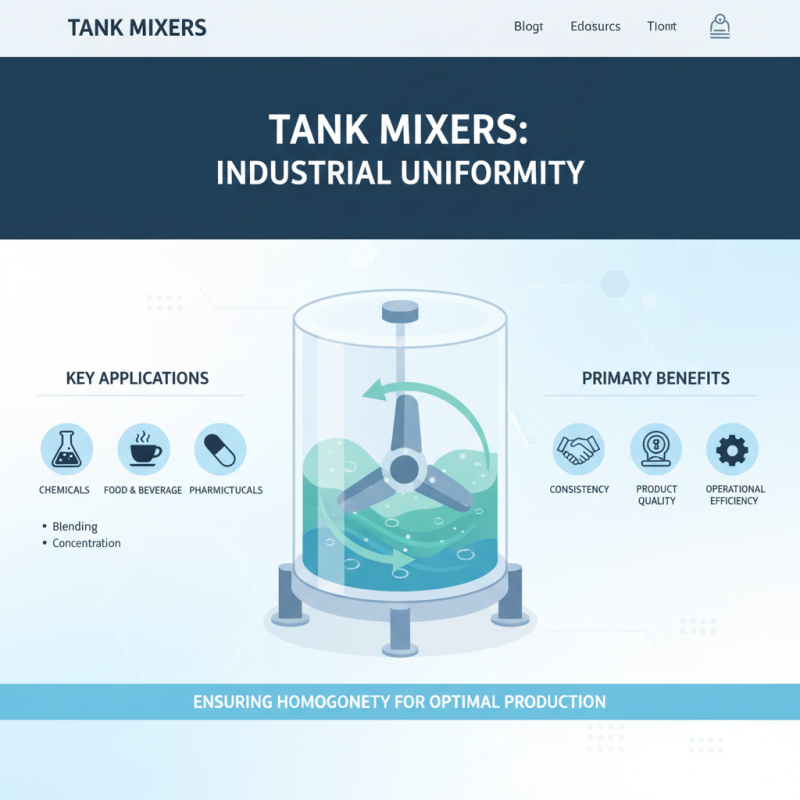

Understanding the Importance of Tank Mixers in Industrial Applications

Tank mixers play a pivotal role in industrial applications by ensuring uniformity and consistency in various processes. In industries such as chemicals, food and beverage, and pharmaceuticals, the ability to effectively blend materials is crucial. These mixers facilitate the proper dispersion of solids into liquids, maintaining optimal concentrations and preventing issues like sedimentation and phase separation. By promoting homogeneity, tank mixers contribute significantly to product quality and operational efficiency, ultimately affecting the overall output of production processes.

Understanding the specific needs of an application is essential when considering tank mixers. Factors such as the viscosity of the materials, the size and shape of the tank, and the desired mixing speed should be carefully evaluated. A well-chosen mixer not only enhances the mixing process but also minimizes energy consumption and reduces maintenance costs. Thus, investing time in selecting the appropriate tank mixer can lead to improved performance and significant long-term savings in industrial operations. This strategic choice ultimately supports the goal of achieving high-quality products while maximizing operational efficiency.

Key Factors to Consider When Selecting a Tank Mixer

When selecting the right tank mixer for your industrial needs, it’s essential to take several key factors into consideration. The type of materials being mixed is a primary consideration, as different materials require specific mixing techniques. For instance, Viscosity levels play a crucial role; according to the American Society of Mechanical Engineers (ASME), dealing with fluids that have a viscosity exceeding 1,000 cP often necessitates specialized high-viscosity mixers to achieve effective homogenization. Additionally, the specific gravity of the materials can impact the design of the mixer, influencing its efficiency and functionality.

In addition to material properties, the tank's design and operational parameters are also vital. The dimensions and shape of the tank can significantly affect the mixing process. For example, tall tanks may require different mixing strategies than short, wide ones. The mixing speed is another critical factor; data from the Mixing Equipment Manufacturers Association (MEMA) suggests that even a minor variation in RPM can lead to substantial differences in product consistency.

**Tips:** When evaluating your tank mixing needs, consider conducting a small-scale test with your specific materials. This will help you gauge the effectiveness of the mixing process before making a larger investment. Also, it can be beneficial to consult with engineers who specialize in mixing technologies to tailor a solution that meets your unique operational requirements.

2025 How to Choose the Right Tank Mixer for Your Industrial Needs

This bar chart illustrates the key factors to consider when selecting a tank mixer for industrial applications, based on their importance ratings from various industry professionals.

Types of Tank Mixers and Their Specific Applications

When selecting the right tank mixer for industrial applications, it's crucial to understand the variety of mixer types available and their specific functions. Among the most commonly used types are propeller mixers, turbine mixers, and magnetic mixers. Propeller mixers, known for their efficiency in general mixing tasks, are particularly effective in low-viscosity fluids and can achieve an optimal shear rate, making them suitable for applications in the food and beverage industry. According to a report by the Mixing Equipment Manufacturers Association (MEMA), propeller mixers account for approximately 40% of the tank mixer market due to their versatility and effectiveness.

Turbine mixers are designed for more demanding applications, particularly when dealing with higher viscosities or when solid suspension is required. Their unique design allows for the mixing of more viscous materials, such as pastes or slurries, which are common in industries like pharmaceuticals and chemical manufacturing. A 2022 industry report highlighted that turbine mixers are preferred in over 30% of mixing applications where maintaining homogeneity is critical, showcasing their importance in specialized processing environments.

Magnetic mixers, on the other hand, offer a unique advantage by providing a closed and sanitary mixing solution, which is crucial in industries like biotechnology and pharmaceuticals. They prevent contamination and are efficient for delicate or reactive materials. Emerging data indicates that the demand for magnetic mixers is projected to grow by 25% over the next five years, driven by increasing hygiene standards and technological advancements. This growth reflects the industry's need for specialized mixing solutions that cater to evolving operational challenges. Understanding these mixer types and their applications is essential for choosing the right equipment tailored to specific industrial needs.

2025 How to Choose the Right Tank Mixer for Your Industrial Needs - Types of Tank Mixers and Their Specific Applications

| Mixer Type | Application | Benefits | Typical Industries |

|---|---|---|---|

| High Shear Mixer | Emulsifying, Homogenizing | Uniformity, High Efficiency | Food, Cosmetics, Pharmaceuticals |

| Gear Drive Mixer | General Mixing, Liquid-Liquid | Durability, High Torque | Chemicals, Water Treatment |

| Magnetic Drive Mixer | Non-contact Mixing, Small Volumes | No Seal Wear, Easy Maintenance | Laboratories, Research |

| Portable Mixer | Batch Mixing, On-site | Flexibility, Cost-Effective | Construction, Agriculture |

| Submersible Mixer | Sludge Mixing, Wastewater Treatment | Effective for High Volume | Municipal, Industrial |

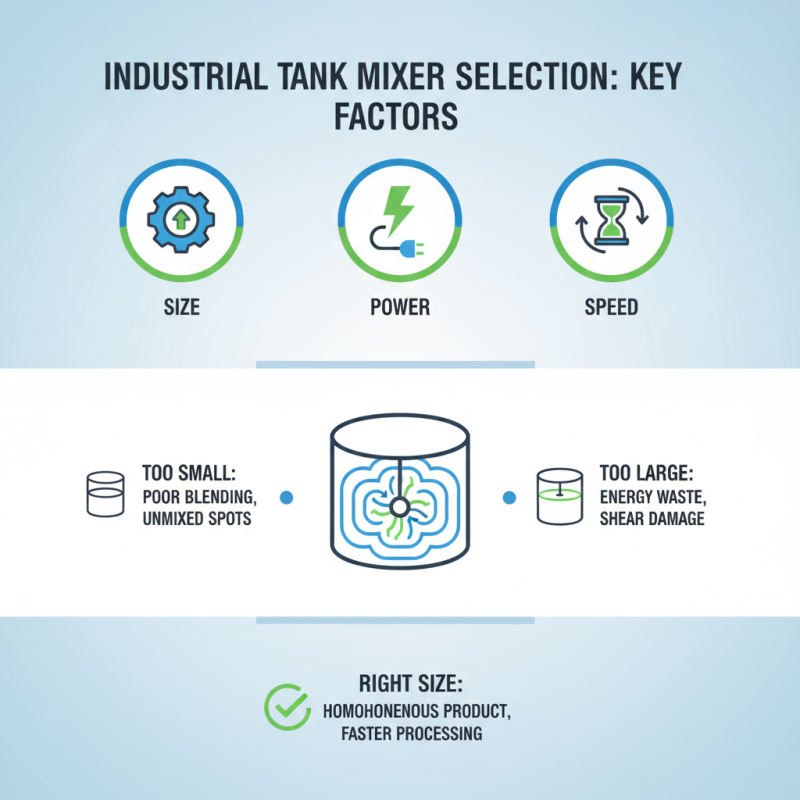

Evaluating Mixer Specifications: Size, Power, and Speed Requirements

When selecting the right tank mixer for industrial applications, evaluating mixer specifications is crucial. Key factors such as size, power, and speed requirements can significantly influence the efficiency and effectiveness of mixing operations. According to industry reports, the right mixer size can enhance product homogeneity and minimize processing times. For instance, a mixer that is too small may lead to insufficient flow patterns, leaving unmixed materials, while a mixer that is too large might require excessive energy and cause shear damage to sensitive components.

Power requirements are another critical aspect of mixer selection. Typically, the mixing process is power-intensive, and selecting a mixer with the appropriate horsepower ensures optimal performance without unnecessary energy consumption. A study by the Mixing Technology Institute indicates that for chemical processes, a power input in the range of 1 to 5 hp per 1,000 gallons of liquid is often effective, depending on the specific application. Moreover, speed requirements can determine the degree of mixing and shear forces, with lower speeds being ideal for delicate products and higher speeds better suited for emulsions and suspensions.

Tips: Always conduct a thorough analysis of your mixing needs prior to selecting a mixer. Take into account not only the physical properties of the materials but also how they react to different mixing conditions. Additionally, consulting with industry experts can provide valuable insights into which specifications will yield the best results for your specific application. Remember to factor in future scalability and operational costs when making your decision to ensure long-term viability.

Best Practices for Installation and Maintenance of Tank Mixers

When it comes to the installation of tank mixers, proper planning is crucial to ensure optimal performance and efficiency. Begin by assessing the specific requirements of your mixing process, including the viscosity of the material, tank dimensions, and the desired mixing speed. This information will help in selecting the right type of mixer and positioning it correctly within the tank. It's essential to install the mixer at the appropriate height to avoid dead zones and to ensure uniform mixing throughout the liquid. Additionally, ensure that all electrical and mechanical components are correctly connected and comply with safety regulations to prevent any operational hazards.

Maintenance is equally important for the longevity and effectiveness of tank mixers. Regularly inspect the mixer for signs of wear and tear, particularly on the blades and seals, as these components often experience the most stress during operation. Establish a routine maintenance schedule that includes cleaning the mixer to avoid buildup of materials that could affect performance and to extend the lifespan of the equipment. Monitoring the mixer’s performance parameters such as vibration and noise levels can also alert you to potential issues before they lead to failure. By implementing these best practices in installation and maintenance, you can ensure that your tank mixer operates reliably and efficiently, meeting the demands of your industrial needs.

Related Posts

-

Top 5 Tank Mixers to Boost Your Efficiency in 2025

-

Essential Tank Mixer Guide: Mastering Mixing Techniques for Optimal Results

-

How to Choose the Right Tank Mixer for Your Industrial Needs

-

Innovative Tank Mixer Applications Across Various Industries

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

2025 Top 10 Chemical Metering Pumps for Precision Fluid Control