Blog

How to Choose the Right Diaphragm Metering Pump for Your Needs?

Choosing the right diaphragm metering pump can significantly impact efficiency in various industries. The global metering pump market is projected to grow from $3.3 billion in 2021 to $4.6 billion by 2026, according to a recent industry report. This illustrates a rising demand for precise fluid handling solutions, especially in sectors like water treatment and chemical processing.

Diaphragm metering pumps offer a reliable way to control flow rates. They are known for their accuracy and durability. However, selecting the right model requires careful consideration of multiple factors. The application's viscosity and pressure requirements must be evaluated. Moreover, not every diaphragm metering pump suits all conditions. Understanding these nuances is essential for maximizing performance.

In some instances, companies may overlook critical specifications, resulting in inefficiencies. Temperature ranges and materials of construction can lead to unexpected failures. This highlights the importance of a methodical approach in selection. Gathering data about the specific operation process can prevent future complications. Ultimately, the right choice ensures reliability and cost-effectiveness in fluid management.

Understanding Diaphragm Metering Pumps: An Overview

Diaphragm metering pumps are essential in various industries. They accurately deliver precise amounts of fluids. These pumps work by using a diaphragm that moves up and down. This motion creates suction and discharge of the liquid. They are versatile and can handle different fluid types.

When choosing a diaphragm metering pump, consider flow rate and pressure. An inaccurate flow rate can lead to operational issues. It’s vital to assess the chemical compatibility of the pump materials. Some materials may degrade with aggressive fluids. The environment where the pump will operate is also critical. High temperatures and corrosive surroundings can impact performance.

Reflecting on your needs is important. Assessing your application's specifics can seem overwhelming. A mismatch in selection may cause operational failures. Take the time to evaluate your requirements. Proper research can lead to informed decisions. Your choice of metering pump can enhance efficiency and reduce downtime.

Understanding Diaphragm Metering Pumps: Performance Comparison

This chart illustrates the flow rates of different diaphragm metering pumps, showcasing their performance across various applications.

Key Factors to Consider When Choosing a Diaphragm Metering Pump

When choosing a diaphragm metering pump, several key factors demand your attention.

The flow rate is fundamental. Most standard pumps handle rates from

1 to 150 GPH. Evaluate your system's specific requirements.

Too low a flow may lead to inefficiencies. Conversely, too high can cause overflow or damage.

Pressure capability is equally crucial. Look for pumps that can sustain the necessary

pressure levels, typically measured in PSI. A good diaphragm pump often operates

effectively at 40 – 100 PSI. Actual application may require adjustments.

Don't overlook the liquid's characteristics, like viscosity and corrosiveness, as these can impact pump selection.

Tips:

- Always analyze compatibility with the fluid being pumped.

- Consider maintenance needs; some pumps require more care than others.

- Research and gather data on service life reports, focusing on common failure points.

Selecting a diaphragm metering pump is not just about numbers. It's about understanding your unique needs and the conditions under which the pump will operate. Taking time to evaluate can prevent expensive mistakes later.

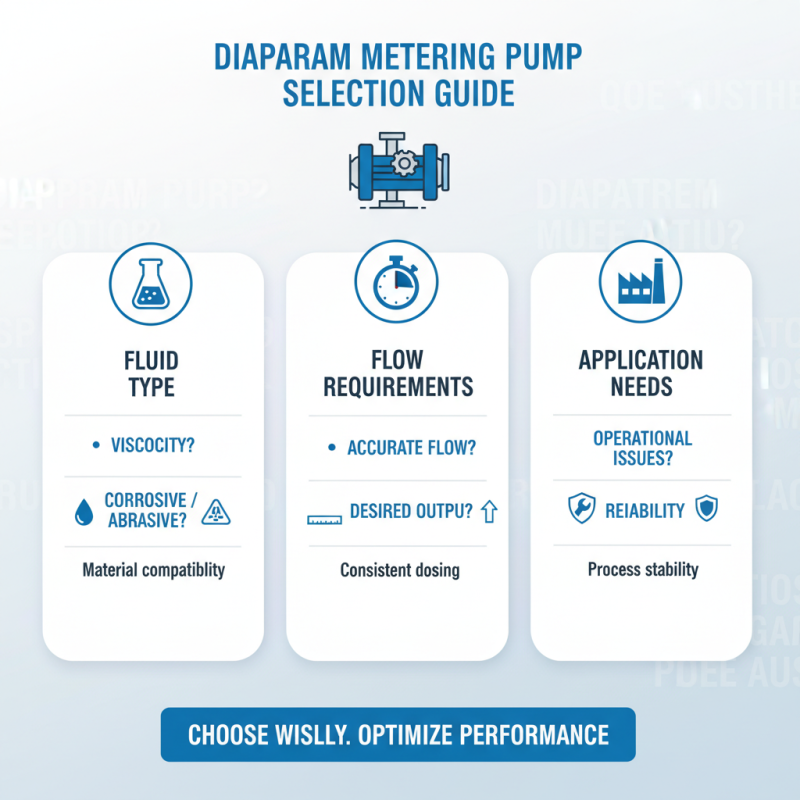

Assessing Your Application Requirements for Metering Pumps

When choosing a diaphragm metering pump, understanding your application requirements is crucial. Consider the fluid being dispensed. Viscosity impacts how a pump performs. Is it a corrosive or abrasive substance? This can dictate the material used in the pump. Accurate flow rates are vital. What is the desired output? If it's inconsistent, it can lead to operational issues.

Think about the environment where the pump will operate. High temperatures can affect performance. Are there vibrations or potential hazards? These factors may require additional features. If you need to monitor the flow rate, an integrated control system is useful. Some pumps offer alerts for maintenance needs, which can be a lifesaver.

You also need to think about installation and maintenance. Will it fit in your current setup? Sometimes, space limitations create challenges. Regular maintenance can prevent breakdowns. But are you prepared for that? The right solution is about balancing specifications and practical considerations. Troubleshooting can take time, so choosing the right pump is not just about the numbers. It's about the entire process.

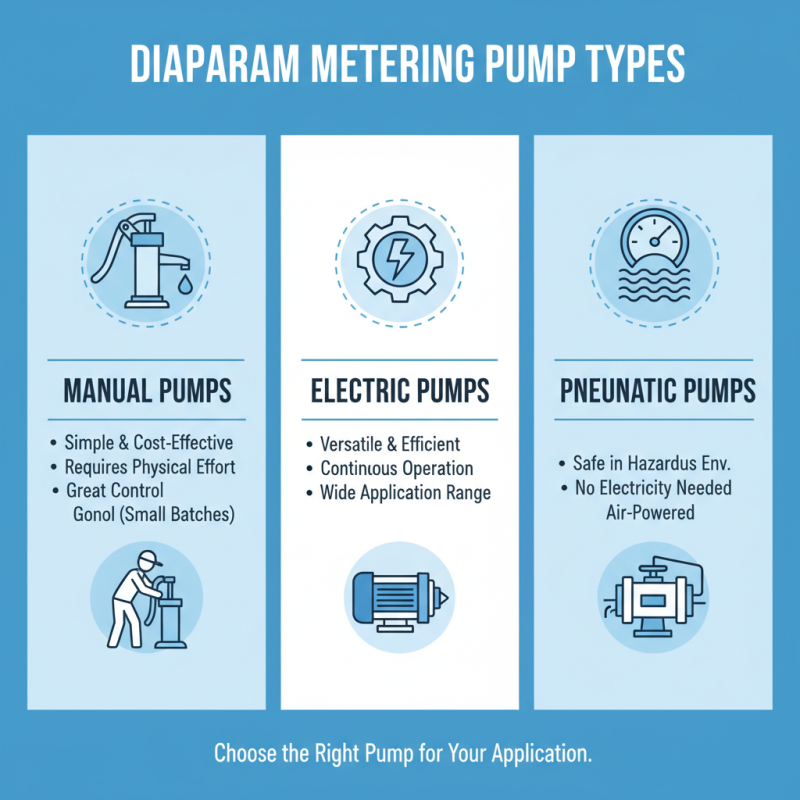

Comparing Different Types of Diaphragm Metering Pumps

When selecting a diaphragm metering pump, understanding the different types is crucial. There are several options available, including manual, electric, and pneumatic pumps. Each type has unique features that make it suitable for specific applications. Manual pumps are simple and cost-effective. They require physical effort but offer great control for small batches. Electric pumps are versatile and efficient, ideal for continuous operations. Pneumatic pumps work well in hazardous environments, as they do not require electricity.

Consider the flow rate and pressure requirements of your application. Some diaphragm pumps have adjustable flow rates, while others are fixed. This variety influences your choice. It's important to assess the materials used in the pump construction. Certain chemicals could corrode less robust materials. For instance, a pump might handle water well but falter under acidic conditions.

Be aware of maintenance needs as well. Some pumps require frequent maintenance, while others are more robust. Neglecting maintenance can lead to failures. Additionally, the size and footprint of the pump should fit your workspace. A large pump may not be appropriate for limited spaces. Balancing all these factors can lead to a more informed decision. Each choice has potential drawbacks that should be carefully examined.

Maintenance and Support Options for Diaphragm Metering Pumps

When considering diaphragm metering pumps, maintenance is key to ensuring optimal performance. Regular checks on wear components can prevent failure. Research indicates that over 30% of pump failures stem from inadequate maintenance. Simple tasks like checking for leaks or listening for unusual sounds can extend a pump’s lifespan significantly.

Support options vary widely in the industry. Some manufacturers offer 24/7 customer service, while others may have limited support hours. Access to expert guidance is crucial. A survey revealed that 65% of operators consider support quality as a top factor when selecting a pump. Investing in extended warranty options might also provide peace of mind but can be costly.

It’s essential to reflect on your specific needs. Do you have the resources for routine maintenance? What level of support can you realistically expect? Weighing these factors can help avoid dissatisfaction down the line. Without a solid maintenance plan and clear support options, even the best diaphragm pump may underperform.

How to Choose the Right Diaphragm Metering Pump for Your Needs? - Maintenance and Support Options for Diaphragm Metering Pumps

| Feature | Description | Maintenance Frequency | Support Options |

|---|---|---|---|

| Flow Rate | Determines the pump capacity, typically measured in GPH or LPH. | Monthly checks recommended | Phone support available for operational issues |

| Pressure Rating | The maximum pressure the pump can handle, essential for high-viscosity fluids. | Quarterly inspection | Online documentation and troubleshooting guides |

| Chemical Compatibility | Ensures materials of the pump can handle the chemicals being pumped. | Annual review of chemical usage | Dedicated account manager for ongoing support |

| Size and Porting Configuration | Dimensions and layout fitting for installation space. | Semi-annual maintenance check | Field technicians available for installations and repairs |

| Control Options | Manual vs automated control systems for operation. | Regular software updates suggested | 24/7 technical support hotline |

Related Posts

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

10 Unique Metering Pump Types You Should Know About

-

Understanding the Benefits of Chemical Metering Pumps in Modern Water Treatment Systems

-

Understanding the Mechanics of Diaphragm Pumps: The Key to Efficient Fluid Transfer

-

2025 Guide to Choosing the Best Chemical Injection Pumps for Your Needs