Blog

How to Choose the Right Commercial Pump for Your Business Needs

In the ever-evolving landscape of industrial operations, selecting the right commercial pump is crucial for businesses aiming to optimize efficiency and productivity. According to John Smith, a leading expert in fluid dynamics and commercial pumping solutions, "Choosing the correct pump can significantly influence a company's operational success and cost-effectiveness." The extensive range of available commercial pumps, each designed for specific applications and environments, can make this selection process daunting for many business owners.

To effectively navigate this complexity, it is essential to understand the various types of commercial pumps, their functionalities, and how they align with the specific needs of your business. Factors such as flow rate, fluid compatibility, and operational environment must be considered to ensure optimal performance. As technology advances, the capabilities of commercial pumps also expand, presenting businesses with innovative options that can lead to enhanced sustainability and reduced downtime. Ultimately, making an informed decision will set the foundation for improved operational efficiency and long-term growth.

Understanding Your Business Pump Requirements

When selecting the right commercial pump for your business, it's crucial to first understand your specific requirements. Assess the nature of your operations, as different businesses may have vastly different pumping needs. For instance, if your business involves moving large volumes of liquid, you'll need a pump with a higher flow rate and pressure capacity. On the other hand, if you're dealing with smaller quantities or more viscous fluids, your requirements may lean towards specialized pumps optimized for those conditions.

Additionally, it’s important to consider factors such as the fluid characteristics, operating environment, and frequency of use. The temperature, chemical composition, and particulates in the fluid can all impact the type of pump that would best suit your needs. Furthermore, evaluate the infrastructure of your facility; space constraints may dictate the size and configuration of the pump systems you can effectively utilize. By thoroughly analyzing these aspects, you can make a more informed decision that aligns with your business goals and operational efficiency.

Types of Commercial Pumps Available in the Market

When selecting a commercial pump for business applications, understanding the various types available is crucial to making an informed choice. The market offers several types of pumps, each designed to meet different operational needs. These include centrifugal pumps, positive displacement pumps, and submersible pumps. According to a recent report by the Global Market Insights, the centrifugal pump segment is expected to dominate the market due to its efficiency in various water treatment and manufacturing processes, accounting for over 40% of the total market share by 2025.

Centrifugal pumps are optimal for transferring low-viscosity fluids and are commonly used in industrial, municipal, and agricultural applications. Positive displacement pumps, on the other hand, are ideal for handling high-viscosity fluids and are often utilized in chemical processing and food production industries. Lastly, submersible pumps are designed for underwater use, making them suitable for applications like dewatering and sewage handling. A study from MarketsandMarkets projects that the submersible pump segment will grow at a CAGR of over 6% through 2026, driven by increasing demand in wastewater management.

Tips: When choosing the right pump, assess the specific requirements of your application, including fluid characteristics, flow rate, and pressure needs. Additionally, consider the environmental conditions and space constraints in which the pump will operate. Collaborating with industry professionals can provide insights tailored to your business, ensuring optimal pump selection for your operational demands.

Types of Commercial Pumps and Their Applications

Evaluating Pump Specifications and Performance Criteria

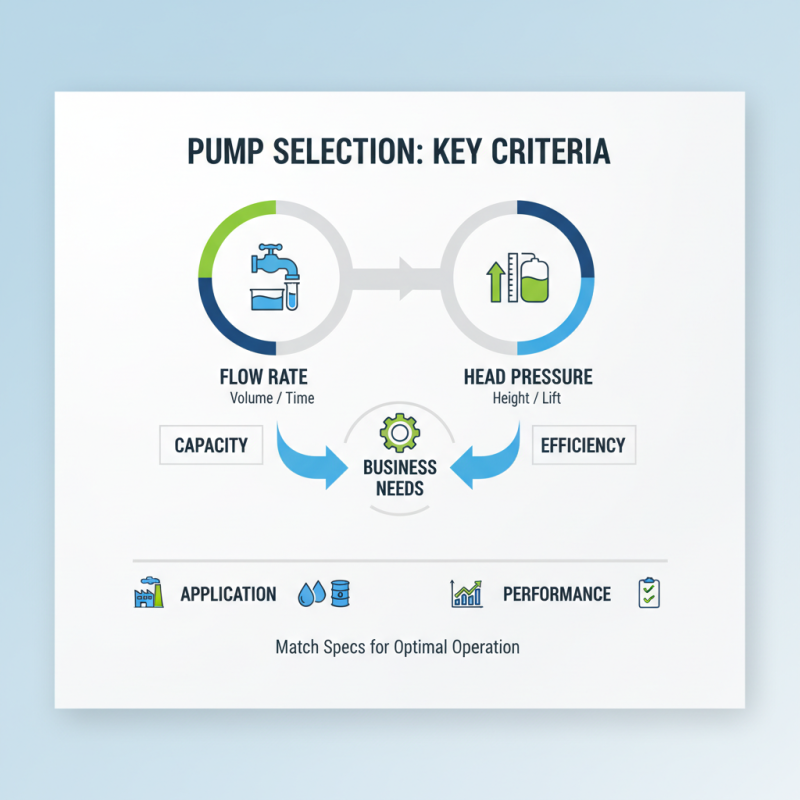

When evaluating pump specifications and performance criteria for your business needs, it's essential to start with understanding the specific requirements of your application. Key parameters include the flow rate, which indicates the volume of fluid the pump can move within a given time frame, and the head pressure, which refers to the height to which the pump can effectively lift the fluid. These specifications will help you determine the pump's capacity to handle the demands of your operations and ensure efficiency in performance.

Additionally, assess the pump's operating conditions, such as the type of fluid it will be moving—whether it's clean water, slurry, or corrosive substances—as this will influence both material selection and design. Pay attention to the pump's NPSH (Net Positive Suction Head) requirements, as inadequate NPSH can lead to cavitation and damage the pump. Other important performance criteria include energy efficiency and maintenance needs, which can significantly impact the long-term operational costs of the pumping system. Selecting a pump that aligns well with these specifications and performance benchmarks will lead to enhanced reliability and productivity within your business.

Assessing Installation and Maintenance Needs for Pumps

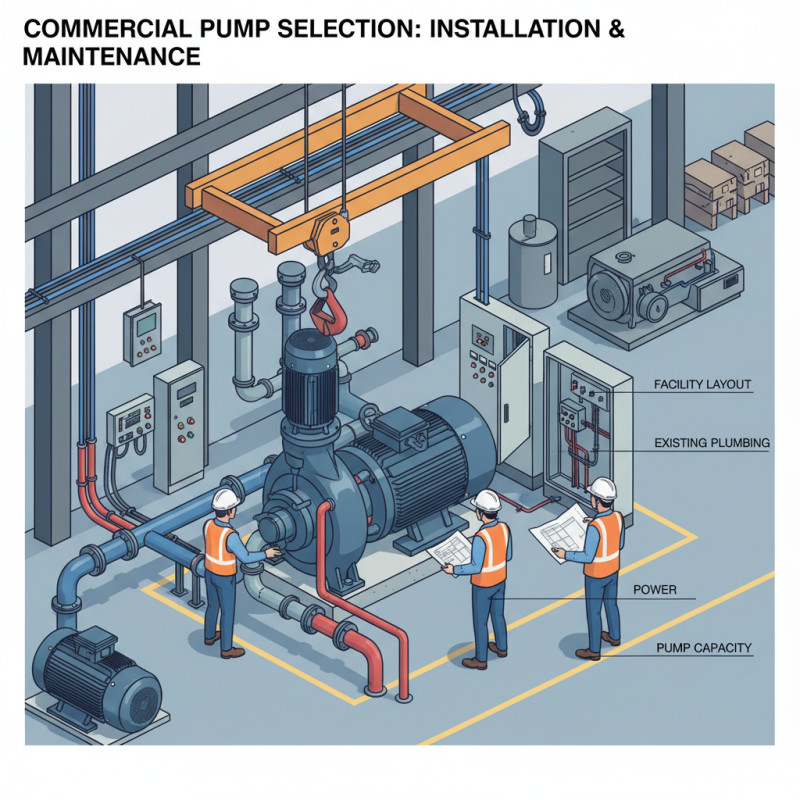

When selecting a commercial pump for your business, it's essential to consider the installation and maintenance needs specific to your operational context. The installation process can vary greatly depending on the type of pump and the physical environment in which it will be placed. Factors such as the layout of your facility, available power sources, and existing plumbing systems should be evaluated. Additionally, assessing the pump's size and capacity will help ensure it integrates seamlessly with your current workflow, minimizing potential disruptions during setup.

Maintenance is another critical aspect to consider when choosing a pump. Regular maintenance not only extends the lifespan of the pump but also ensures optimal performance. Establishing a routine maintenance schedule can help identify potential issues before they turn into costly repairs. Understanding the maintenance requirements, such as the need for lubrication, replacement parts, and any specific tools needed for upkeep, can inform your purchasing decision. Investing in a pump that aligns with your capacity for maintenance will lead to greater efficiency and reliability in your operations.

Budgeting for Purchase and Long-term Operational Costs

When selecting a commercial pump, understanding the budgeting for both the initial purchase and long-term operational costs is crucial. According to the Hydraulic Institute, a leading organization representing the pump industry, more than 30% of a pump's total lifecycle cost comes from energy consumption, significantly affecting the overall expenditure. Therefore, businesses should consider energy-efficient pump systems that may have a higher upfront cost but lead to substantial savings over time. Investing in pumps with high-efficiency motors can reduce operational costs by up to 20% compared to standard motors, offering long-term financial benefits.

Additionally, maintenance and repair costs must be factored into the budget. A study by the American Society of Mechanical Engineers indicates that poorly maintained pump systems can lead to increased premature failures and higher repair costs, which can reach up to 10% of the initial investment annually. Implementing a preventive maintenance plan not only prolongs the life of pumps but also reduces unexpected downtime, allowing businesses to allocate funds more effectively and improve overall operational efficiency. Therefore, a comprehensive understanding of both upfront and ongoing costs will enable businesses to choose the right commercial pump that aligns with their financial objectives and operational needs.

How to Choose the Right Commercial Pump for Your Business Needs - Budgeting for Purchase and Long-term Operational Costs

| Pump Type | Initial Cost ($) | Energy Efficiency Rating | Estimated Annual Operational Cost ($) | Maintenance Cost (Annual) ($) | Expected Lifespan (Years) |

|---|---|---|---|---|---|

| Centrifugal Pump | 3,000 | B | 600 | 300 | 10 |

| Positive Displacement Pump | 4,500 | A | 650 | 400 | 12 |

| Submersible Pump | 2,200 | C | 550 | 200 | 8 |

| Diaphragm Pump | 3,800 | A | 700 | 350 | 10 |

| Gear Pump | 5,500 | B | 800 | 450 | 15 |

Related Posts

-

How to Optimize Pump Technology for Increased Efficiency and Reduced Costs

-

Understanding the Role of Industrial Metering Pumps in Modern Manufacturing Processes

-

How to Choose the Right Types of Pumps for Your Industrial Needs: A Comprehensive Guide

-

How to Choose the Right Pump Systems for Your Specific Needs

-

2025 Top Metering Pump Innovations for Precision Fluid Control

-

Understanding the Importance of Diaphragm Metering Pumps in Precision Fluid Control