Blog

How to Choose the Right Chemical Diaphragm Pump for Your Application

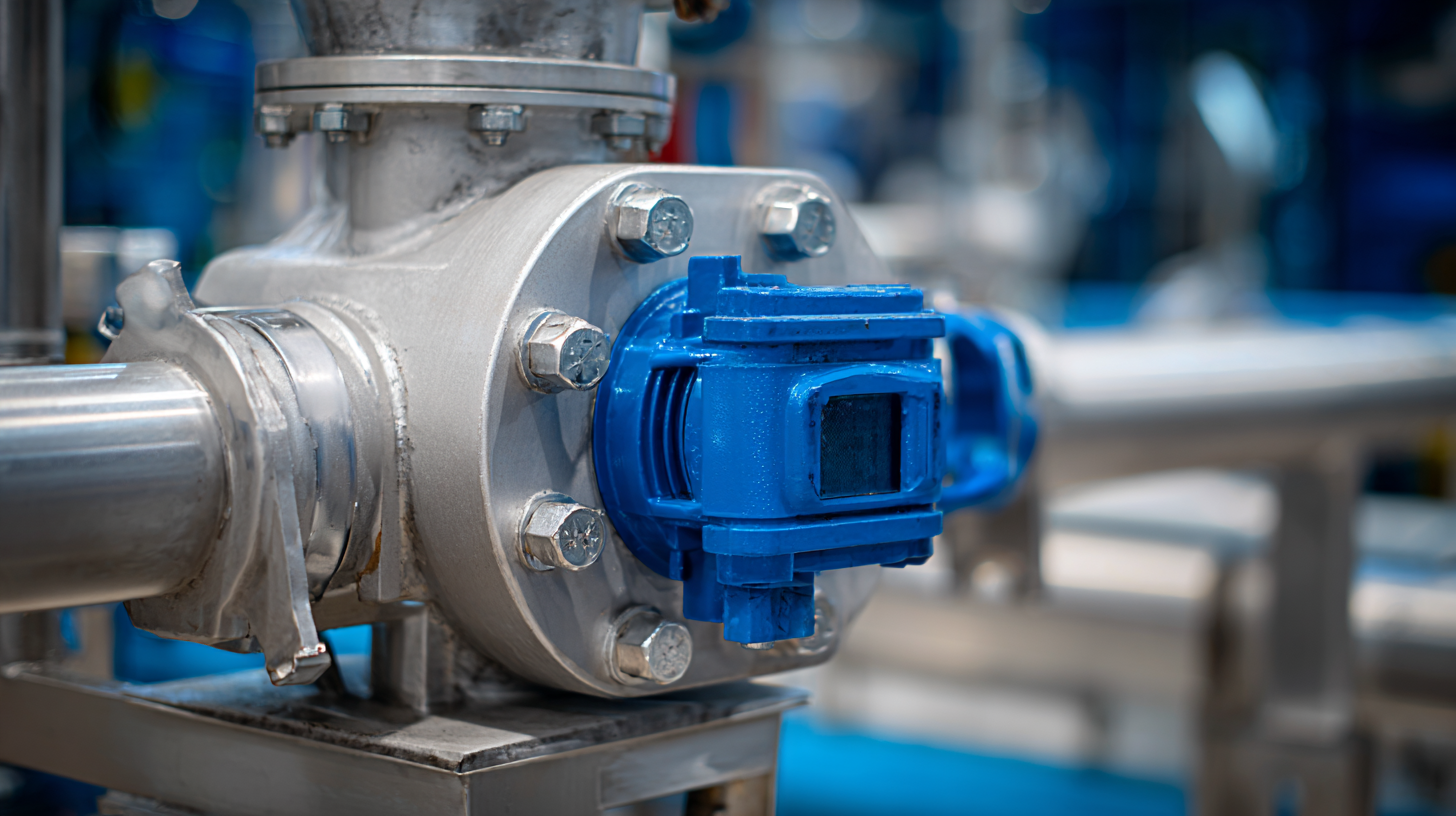

In the expanding landscape of industrial applications, the significance of selecting the appropriate chemical diaphragm pump cannot be overstated. According to a recent report from Transparency Market Research, the global diaphragm pump market is anticipated to reach USD 4.2 billion by 2026, growing at a CAGR of 5.9% from 2018 to 2026, driven by increasing demand across diverse sectors such as water treatment, chemical processing, and pharmaceuticals. The efficiency and reliability of a chemical diaphragm pump can influence operational costs and safety in pumping corrosive and hazardous substances. Therefore, understanding key specifications such as flow rate, pressure range, and material compatibility is crucial for optimizing performance and ensuring longevity. This guide will provide essential tips and insights to assist in making an informed decision tailored to your specific application needs.

Factors to Consider When Selecting a Chemical Diaphragm Pump

When selecting the right chemical diaphragm pump for your application, several key factors must be considered to ensure optimal performance and longevity. First, the chemical compatibility of the pump materials is crucial. Different chemicals can cause degradation in materials like rubber or plastic, leading to leaks and failures. Therefore, it's essential to assess the properties of the fluids being pumped and choose materials that can withstand the specific corrosive or abrasive nature of those chemicals.

Another important factor is the pump's flow rate and pressure requirements. Understanding the operational parameters of your system will help you select a pump that can deliver the necessary flow without excessive energy consumption or wear and tear. Additionally, consider the installation conditions—such as available space and mounting options—as these can influence your choice. Overall, by carefully evaluating these factors, you can select a diaphragm pump that meets both your technical needs and safety standards, ensuring a reliable solution for your chemical processing tasks.

Types of Chemical Diaphragm Pumps and Their Applications

When selecting a chemical diaphragm pump, understanding the different types and their specific applications is crucial. There are primarily three types of chemical diaphragm pumps: air-operated pumps, electric diaphragm pumps, and hydraulic diaphragm pumps. Air-operated pumps, renowned for their versatility, are widely used in industries like water treatment and chemical processing due to their ability to handle corrosive fluids. According to a 2022 report by the Global Diaphragm Pump Market Research, air-operated pumps dominate the market, accounting for nearly 50% share due to their ease of use and maintenance.

Electric diaphragm pumps are favored for applications that require precise flow rates and are commonly employed in pharmaceuticals and food processing industries. These pumps provide better control, reducing the risk of leaks or contamination. Moreover, hydraulic diaphragm pumps are designed for high-pressure applications, making them ideal for harsh environments such as mining and oil and gas extraction. Industry reports indicate a growing trend towards electric diaphragm pumps, expected to experience a 6% annual growth rate over the next five years, driven by strict regulations on fluid handling in sensitive applications. Understanding these variations helps businesses optimize their operations and ensure compliance with industry standards.

Types of Chemical Diaphragm Pumps and Their Applications

This chart illustrates the various types of chemical diaphragm pumps and their applications across different industries. Air-operated pumps are widely used in many sectors, while electric pumps dominate in more specialized applications.

Evaluating Pump Materials for Chemical Compatibility

When selecting the right chemical diaphragm pump, one of the most crucial factors to consider is the compatibility of the pump materials with the fluids being transferred. Different chemicals can interact adversely with various materials, leading to degraded performance or even pump failure. For instance, certain acids may corrode metals, while solvents could damage plastics over time. It's essential to know the chemical properties of the fluid, such as its pH level, temperature, and whether it contains abrasive particles or is prone to crystallization.

To ensure optimal performance and longevity, manufacturers often provide guidelines on material selection based on common chemicals. Materials like PTFE, PVDF, and various elastomers are frequently chosen for their resistance to chemical attack. Additionally, consulting chemical compatibility charts can offer insights into how different materials hold up under specific conditions. By carefully evaluating the chemical compatibility of pump materials, users can avoid costly downtime and ensure their systems run smoothly, enhancing operational efficiency in the long run.

Understanding Flow Rates and Pressure Requirements

When selecting a chemical diaphragm pump for your application, understanding the flow rates and pressure requirements is crucial. Flow rate, typically expressed in gallons per minute (GPM) or liters per minute (L/min), directly impacts the efficiency of your system. It’s essential to determine the volume of liquid you need to move and how quickly you need it processed. For example, a high-flow application, such as transferring bulk chemicals, will require a pump capable of maintaining a consistent flow rate without fluctuations that could compromise the system’s integrity.

On the other hand, pressure requirements play a vital role in ensuring that the pump can handle the necessary resistance encountered within the system. Factors such as the elevation difference between the source and discharge points, as well as the viscosity of the fluid, will influence this requirement. Selecting a pump that meets these pressure needs prevents operational issues such as cavitation or reduced flow efficiency. Therefore, a comprehensive evaluation of both flow rate and pressure specifications tailored to your specific application ensures optimal performance and longevity of the diaphragm pump.

Maintenance Tips for Longevity of Your Diaphragm Pump

When it comes to maintaining the longevity of your diaphragm pump, regular maintenance is crucial. One of the key practices is routine inspection of the pump components, including the diaphragm, seals, and valves. Look for signs of wear or damage, such as cracks or leaks, which can lead to decreased performance or potential pump failure. Establish a regular schedule for these inspections to catch any issues early and ensure optimal operation.

When it comes to maintaining the longevity of your diaphragm pump, regular maintenance is crucial. One of the key practices is routine inspection of the pump components, including the diaphragm, seals, and valves. Look for signs of wear or damage, such as cracks or leaks, which can lead to decreased performance or potential pump failure. Establish a regular schedule for these inspections to catch any issues early and ensure optimal operation.

Another vital aspect of pump maintenance is ensuring proper lubrication. Diaphragm pumps typically have specific lubrication requirements based on the materials used in their construction. Be sure to use the recommended lubricants and follow the manufacturer's guidelines to prevent premature wear and tear. Additionally, keep the pump clean and free from debris that could interfere with its function. Implementing these maintenance tips will not only extend the lifespan of your diaphragm pump but also enhance its efficiency and reliability in your application.

Related Posts

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Innovative Tank Mixer Applications Across Various Industries

-

5 Essential Benefits of Using a Chemical Mixer for Your Manufacturing Process

-

How to Choose the Right Industrial Pumps for Your Manufacturing Needs