Blog

2025 How to Choose the Right Chemical Injection Pumps for Your Needs

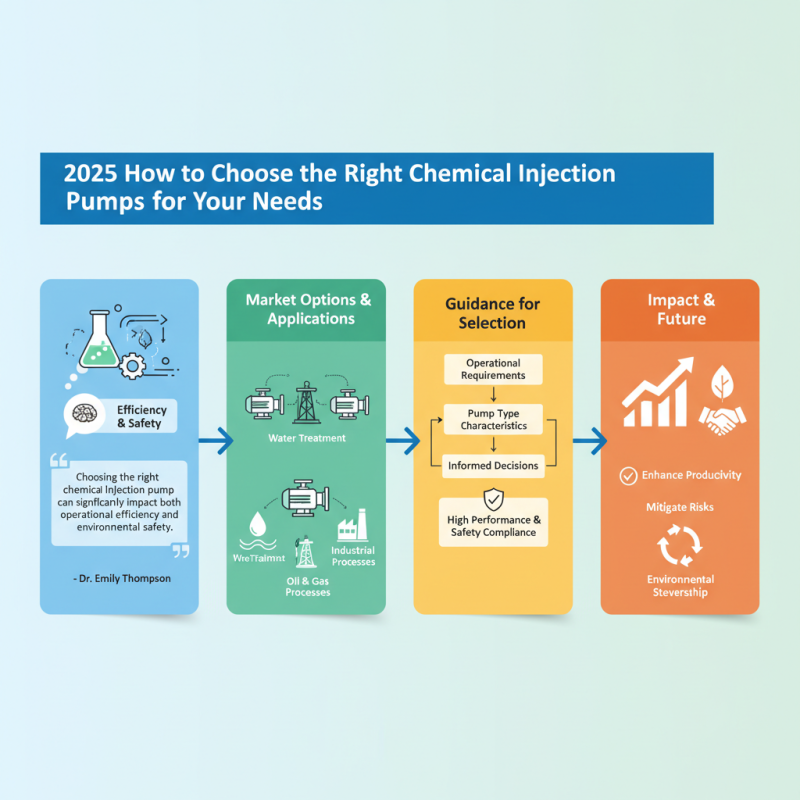

In the evolving landscape of industrial processes, the selection of appropriate chemical injection pumps plays a crucial role in optimizing efficiency and safety. As noted by Dr. Emily Thompson, a leading expert in fluid dynamics and chemical engineering, "Choosing the right chemical injection pump can significantly impact both operational efficiency and environmental safety." This statement underscores the importance of making informed decisions when it comes to the installation and utilization of these critical devices.

The market for chemical injection pumps offers a myriad of options, each designed to meet specific needs across various industries. With applications ranging from water treatment to oil and gas production, understanding the operational requirements and the specific characteristics of different pump types is essential. This article aims to guide you in navigating the complexities of selecting the right chemical injection pumps tailored to your unique operational needs, ensuring both high performance and compliance with safety standards.

In today’s dynamic industrial environment, the right choice not only enhances productivity but also mitigates potential risks associated with chemical handling and application. By leveraging insights from industry experts and evaluating the various features of chemical injection pumps, businesses can significantly enhance their operational frameworks and contribute positively to environmental stewardship.

Types of Chemical Injection Pumps Available in 2025

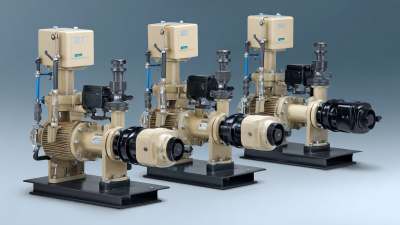

In 2025, the landscape of chemical injection pumps is diverse, catering to various industrial needs. The primary types available include diaphragm pumps, gear pumps, and peristaltic pumps. Diaphragm pumps are known for their reliability and ability to handle corrosive chemicals, making them suitable for industries such as wastewater treatment and chemical processing. Their design allows for precise flow control, minimizing the risk of over-injection, which is crucial for maintaining safety and efficiency.

Gear pumps, on the other hand, excel in high-pressure applications and provide a consistent flow rate. They are particularly effective for viscous fluids and are commonly used in oil and gas industries. Their robust construction ensures durability even under demanding conditions. Lastly, peristaltic pumps offer unique advantages, especially in scenarios requiring sterile conditions, as they minimize the risk of contamination. This type is widely used in pharmaceuticals and food processing industries due to its gentle handling of fluids.

Choosing the right type of chemical injection pump involves evaluating the specific requirements of your application, including flow rate, pressure, and chemical compatibility. Understanding these various types will help you make an informed decision tailored to your operational needs in 2025.

Key Factors to Consider When Selecting a Chemical Injection Pump

When selecting a chemical injection pump, several key factors come into play to ensure that the chosen equipment meets your specific needs. First and foremost, consider the type of chemicals you'll be injecting. The compatibility of the pump materials with these chemicals is crucial, as it directly affects the pump's longevity and operational efficiency. It’s essential to identify not only the chemical composition but also its viscosity, temperature, and other physical properties.

Another significant factor is the flow rate and pressure requirements for your application. Different processes demand varying rates of chemical delivery. Understanding the required flow rate will help you choose a pump that can maintain the necessary pressure while operating efficiently. Additionally, you should consider the pump's physical size and accessibility for installation and maintenance, especially if space is limited in your facility.

**Tips:** Always consult with chemical experts or pump specialists if you’re uncertain about compatibility or specifications. Regular maintenance is also key to extending the life of your chemical injection pump, so opt for models that allow easy access for service. Finally, factor in the operational environment, such as potential exposure to corrosive agents or extreme temperatures, to ensure durability and reliability of the pump in the long run.

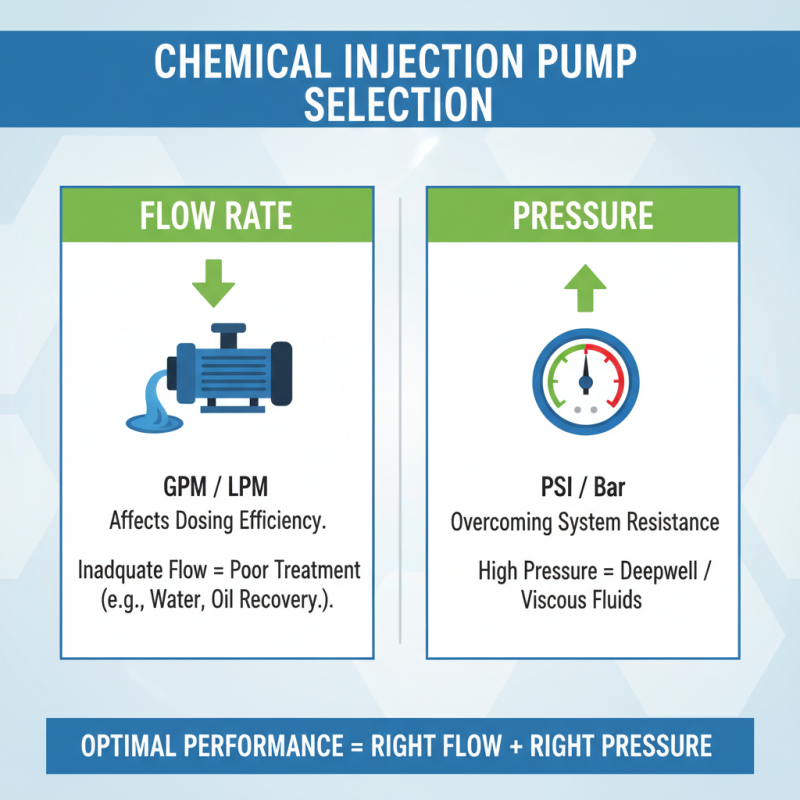

Understanding Flow Rate and Pressure Requirements for Your Application

When selecting the right chemical injection pump for your specific application, understanding flow rate and pressure requirements is crucial. Flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), directly affects the efficiency and effectiveness of chemical dosing. For instance, a study by the American Institute of Chemical Engineers highlights that improper flow rates can lead to inadequate chemical treatment, impacting processes such as water treatment or oil recovery. Identifying your application’s exact flow rate needs ensures optimal performance and cost-effectiveness.

Pressure requirements play an equally vital role in pump selection. The pressure rating, typically expressed in psi or bar, determines the pump's ability to overcome system resistance and deliver the chemical to the desired location. High-pressure applications, like those in hydraulic fracturing, may demand pumps that can sustain pressures exceeding 5000 psi. According to a report by the Hydraulic Institute, matching the pump pressure with system dynamics enables consistent chemical delivery and reduces wear and tear on the equipment.

**Tips:** Always validate flow rate and pressure specifications against the parameters of your system before purchase. Conduct a thorough analysis of your process requirements to avoid inefficiencies. Additionally, consider the chemical properties, such as viscosity and corrosiveness, as they can greatly influence the choice of pump design and materials. Understanding these aspects ensures a reliable and durable pumping solution for your chemical injection needs.

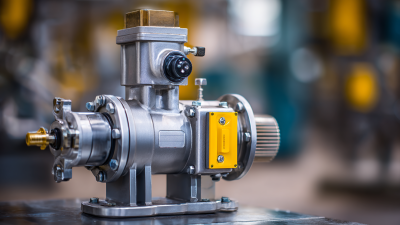

Comparing Durability and Material Options for Chemical Pumps

When selecting chemical injection pumps, one of the most critical factors to consider is the durability of the materials used in construction. Chemical exposure can lead to rapid wear and tear on pumps if they are not made from suitable materials. For instance, stainless steel is often favored for its resistance to corrosion and ability to withstand high pressures, making it a common choice for many industrial applications. In addition, some pumps may feature coatings or linings made from specialized polymers or elastomers, which enhance their ability to handle aggressive chemicals without degrading over time.

Another important aspect to consider is the operating environment where the pump will be utilized. For applications involving harsh chemicals or extreme temperatures, materials such as high-density polyethylene (HDPE) or fluoropolymers may be more appropriate. These materials offer excellent chemical resistance and can maintain their integrity under fluctuating conditions, ensuring optimal performance and longevity of the pumping system. Proper evaluation of these material options not only aids in achieving efficiency and reliability but also minimizes maintenance costs and downtime, essential factors in any chemical handling operation.

Evaluating Cost-Effectiveness and Maintenance Needs of Injection Pumps

When selecting the right chemical injection pumps, one of the most critical factors to consider is the cost-effectiveness versus the maintenance needs. According to recent industry reports, maintenance costs can account for up to 20-30% of a pump's lifecycle expenses. This statistic highlights the importance of evaluating not only the initial purchase price but also the long-term operational costs associated with maintenance and repair. For instance, positive displacement pumps may be more expensive upfront but often require less frequent maintenance, making them a financially sound choice over time.

Moreover, regular maintenance schedules must be factored into the overall cost analysis. A study by the American Society of Mechanical Engineers found that failing to adhere to maintenance protocols can lead to performance degradation, resulting in unplanned downtime and increased operational costs. Organizations should also consider the availability of replacement parts and the expertise required for maintenance. Pumps that are too complex may lead to higher labor costs and longer downtime periods. Therefore, a thorough evaluation of both the cost-effectiveness and maintenance needs of chemical injection pumps is essential to make an informed decision that aligns with operational efficiency and budgetary constraints.

2025 Chemical Injection Pumps: Cost-Effectiveness and Maintenance Needs

Related Posts

-

What is a Chemical Pump? Understanding Types, Uses, and Benefits for Your Industry

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

10 Unique Metering Pump Types You Should Know About

-

7 Essential Tips for Choosing the Right Chemical Injection Pumps

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China