Blog

How to Choose the Best Pump Accessories for Optimal Performance and Efficiency

When it comes to achieving optimal performance and efficiency in pumping systems, the selection of pump accessories plays a crucial role. The right accessories not only enhance the functionality of the pump but also ensure a smoother operation, ultimately leading to cost savings and increased productivity. Understanding the various types of pump accessories available is essential for any operator or maintenance technician aiming to optimize their equipment's capabilities.

In this guide, we will explore the key factors to consider when choosing pump accessories. From connectors and fittings to gauges and control systems, each accessory contributes to the overall effectiveness of your pumping application. It's vital to assess compatibility with your existing equipment and the specific requirements of your operation. By examining the material, design, and performance characteristics of each accessory, you can make informed decisions that lead to improved efficiency and reduced downtime.

As we delve deeper into the intricacies of pump accessories, you will gain insights into how to tailor your choices to fit your specific needs. This knowledge will empower you to enhance not just the performance, but also the longevity of your pumping systems, making it an essential investment for any industry relying on fluid movement.

Understanding Different Types of Pump Accessories Available in the Market

When it comes to optimizing pump performance and efficiency, selecting the right accessories is crucial. There are various types of pump accessories available in the market, each serving specific functions to enhance the overall operation of pumping systems.

Common accessories include filters, strainers, pressure gauges, and flow meters. Filters ensure that the fluid being pumped is free from debris that could damage the pump, while strainers facilitate the removal of larger particles. Pressure gauges provide real-time monitoring, allowing for immediate adjustments to maintain optimal performance.

Tips: When choosing pump accessories, consider the specific application requirements. Evaluate the type of fluid being handled, its viscosity, and the operating conditions of the system to select the most suitable accessories.

It’s also important to check the compatibility of materials with the fluids to avoid corrosion or failure.

Another key category of pump accessories is control devices, which include valves and controllers. These devices help regulate the flow and pressure, maintaining efficiency while reducing energy consumption. Selecting the right type of valve, such as a globe or ball valve, can significantly impact the performance of the pumping system.

Pay attention to the size and capacity of the valves to ensure they match the specifications of your pump for seamless integration.

Factors to Consider When Selecting Pump Accessories for Efficiency

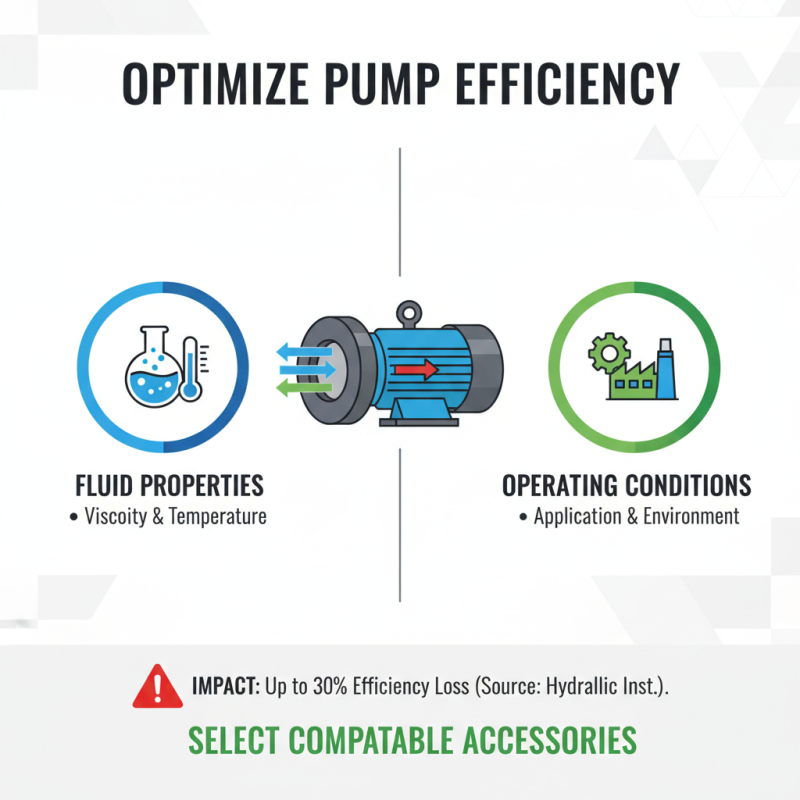

When selecting pump accessories for enhanced efficiency, several critical factors must be considered to optimize performance. Firstly, understanding the specific application and operating conditions of the pump is essential. For instance, the viscosity and temperature of the working fluid significantly influence the choice of accessories. According to a report by the Hydraulic Institute, improper selection of pump accessories can lead to a decrease in efficiency by up to 30%. Therefore, ensuring compatibility with the fluid properties and environmental factors is vital.

Another important consideration is the sizing and material of the pump accessories. Accessories must be appropriately sized to match the pump's capacity, as mismatched sizes can lead to cavitation and increased wear. Additionally, the material should be selected based on chemical compatibility and durability under operational stresses. A study from the American Society of Mechanical Engineers highlights that materials like stainless steel and specific polymers can enhance the longevity and efficiency of pump systems by reducing maintenance requirements. With these factors in mind, one can ensure optimal performance and increased energy efficiency in pump operations.

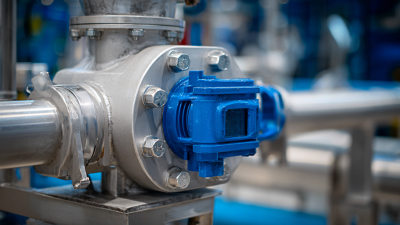

Evaluating Compatibility of Accessories with Your Existing Pump System

When selecting pump accessories, compatibility with your existing pump system is paramount for ensuring optimal performance and efficiency. According to a report by the Hydraulic Institute, nearly 40% of pump failures are attributed to the use of mismatched components. This statistic underscores the necessity of evaluating accessory specifications closely. For instance, the material composition of seals and gaskets should be compatible with the fluids being pumped to prevent degradation and leaks. Additionally, examining the dimensions and connection types is crucial, as improper fittings can lead to system inefficiencies and increased energy consumption.

Moreover, the integration of accessories such as variable frequency drives (VFDs) can significantly enhance pump performance. A study from the U.S. Department of Energy highlighted that implementing VFDs can increase energy savings by up to 50% in variable flow applications. However, not all pumps are designed to handle the changes VFDs introduce. Hence, understanding the operational range and characteristics of your pump is vital before making any upgrades. By performing a thorough compatibility analysis, users can avoid costly downtime and maintain high operational efficiency in their pumping systems.

Optimal Pump Accessories Performance Analysis

This bar chart illustrates the performance metrics of pump accessories for optimal performance and efficiency. The data highlights pump efficiency as a percentage of the ideal, a compatibility score on a scale of 1 to 10, and maintenance frequency in months. These factors are crucial in evaluating the best accessories for your existing pump system.

Maintenance Tips for Maximizing Performance of Pump Accessories

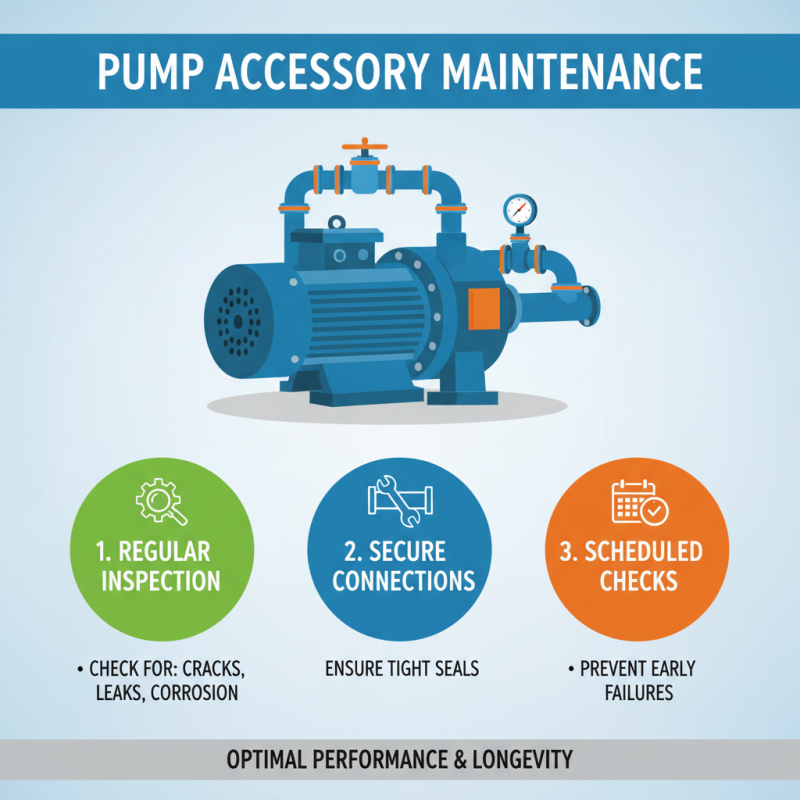

Maintaining pump accessories is crucial for ensuring their longevity and optimal performance. Regular inspection is the first step in maintenance. Check for wear and tear, such as cracks, leaks, or corrosion, as these issues can significantly affect functionality. Additionally, ensure that all connections are secure and that seals are intact to prevent any fluid loss. A regular schedule for these inspections can help catch potential problems early and keep the system running smoothly.

Another important aspect of maintenance is cleaning. Over time, pump accessories can accumulate dirt, debris, and other contaminants that hinder performance. Periodically cleaning these components not only enhances efficiency but also helps prevent blockages that could lead to pump failure. Using the appropriate cleaning solutions and techniques is essential to avoid damaging sensitive parts. Finally, lubricating movable parts as per the manufacturer's recommendations enhances their operation and reduces the risk of overheating or mechanical failure. Adopting these maintenance tips will lead to better performance and extend the life of pump accessories, ensuring reliable operation for years to come.

Emerging Technologies in Pump Accessories for Enhanced Efficiency

Emerging technologies in pump accessories are revolutionizing the industry by significantly enhancing efficiency and performance. Innovations such as smart sensors and IoT-enabled devices are pivotal in optimizing pump operations. These technologies allow for real-time monitoring of pump performance, enabling predictive maintenance and minimizing downtime. By analyzing operational data, users can identify inefficiencies and make informed decisions to improve system performance.

Moreover, advancements in materials science have led to the development of lighter and more durable pump components. This not only reduces energy consumption but also extends the lifespan of the equipment. Advanced coatings and composites can withstand corrosive environments, ensuring reliable operation without frequent replacements. As these emerging technologies continue to evolve, they promise to set new standards in energy efficiency and operational effectiveness for pumping systems across various industries.

Related Posts

-

Harnessing Innovation in Pump Accessories at the 138th Canton Fair 2025 with Market Insights Driving Growth

-

2025 Guide to Choosing the Best Chemical Injection Pumps for Your Needs

-

How to Optimize Pump Technology for Increased Efficiency and Reduced Costs

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

Innovative Chemical Injection Solutions at the 138th China Import and Export Fair 2025

-

Innovative Solutions for Industrial Pumps to Enhance Efficiency and Reduce Costs