Blog

How to Choose the Right Diaphragm Metering Pump for Your Application?

Selecting the right diaphragm metering pump for your specific application is crucial. These pumps offer precision, reliability, and excellent chemical resistance. According to the latest report from the Hydraulic Institute, the diaphragm metering pump market is projected to grow at a CAGR of 6.2% from 2023 to 2030. This growth underscores their importance in various industries, including wastewater treatment and manufacturing.

Dr. Jane Smith, a leading expert in fluid dynamics, emphasizes, "The choice of a diaphragm metering pump can significantly impact operational efficiency." Choosing the correct model involves understanding your needs. This includes flow rate, pressure requirements, and the fluids involved. Many users overlook these details, which can lead to suboptimal performance and increased costs.

Furthermore, considerations like material compatibility and automation options should not be ignored. Some common mistakes include misjudging fluid characteristics and pump specifications. By carefully assessing all factors, you can avoid these pitfalls. The right diaphragm metering pump should enhance your operational capabilities without introducing unnecessary complications.

Understanding Diaphragm Metering Pumps and Their Applications

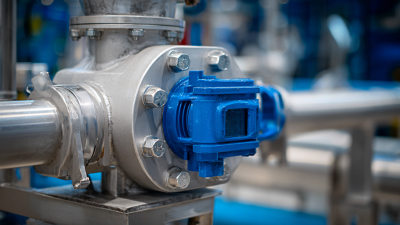

Diaphragm metering pumps play a vital role in various industries. These pumps are designed to transport fluids with precision. They are often used in chemical processing, water treatment, and food production. Understanding how they function helps in choosing the right one for your needs.

One important detail is the construction of diaphragm metering pumps. They use a flexible diaphragm to create a pumping action. This design allows for a precise flow rate, essential for applications requiring accuracy. However, not all diaphragms are the same. Some may wear out faster than others, leading to inconsistent performance.

Considering your specific application is crucial. The type of fluid being pumped affects the pump selection. Viscous fluids require different specifications than water-like liquids. Sometimes, adjustments are needed to optimize the pump's efficiency. It’s essential to evaluate whether the chosen pump meets the demands of your operation. Conducting a thorough analysis will lead to better performance and reduced issues down the line.

How to Choose the Right Diaphragm Metering Pump for Your Application?

| Application | Flow Rate (L/hour) | Pressure (bar) | Fluid Type | Material Compatibility |

|---|---|---|---|---|

| Chemical Injection | 10 - 100 | 5 - 10 | Corrosive Liquids | PTFE, PVC |

| Water Treatment | 20 - 200 | 2 - 5 | Chemicals, Algaecides | Polypropylene, PVDF |

| Food Processing | 5 - 50 | 3 - 8 | Edible Liquids | Stainless Steel, EPDM |

| Agriculture | 15 - 150 | 1 - 4 | Fertilizers, Pesticides | Nitrile, Viton |

Key Factors to Consider When Selecting a Diaphragm Metering Pump

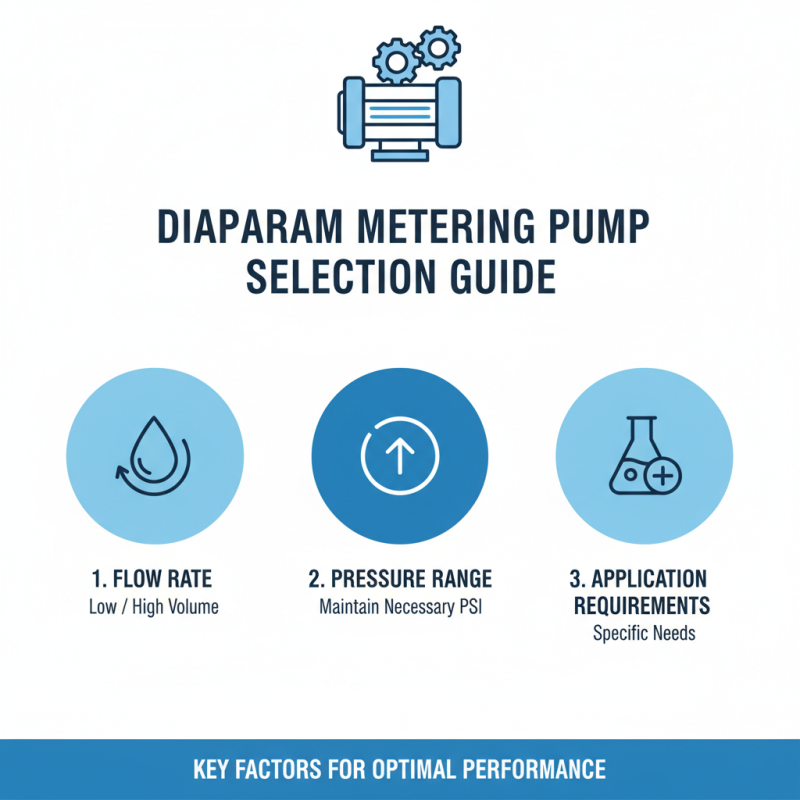

When selecting a diaphragm metering pump, several key factors come into play. The application's specific requirements are paramount. Consider the flow rate needed. Will it need to handle low or high volumes? This directly impacts your choices. Equally important is the pressure range. Ensure the pump can maintain the necessary pressure without failure.

Next, evaluate the fluid being pumped. Is it corrosive, abrasive, or viscous? Different materials will affect the pump's longevity and performance. Understanding these characteristics helps prevent future issues. Installation and maintenance should also be part of your assessment. A pump that is hard to maintain can lead to frustration and downtime.

For many, the operating environment matters, too. Is it indoors or outdoors? What are the temperature fluctuations? These conditions can influence the pump's efficiency. Sometimes, users overlook these details and end up with a suboptimal choice. Ensuring the pump fits well within the context of your system is crucial. A little extra thought here can save time and resources later on.

Evaluating Pump Performance Specifications for Your Needs

When selecting a diaphragm metering pump, performance specifications are crucial. Assess the flow rate needed in your application. This factor determines how well the pump can handle various tasks. For example, some processes require precise dosing, while others may focus on higher throughput.

Next, consider the pressure rating. A pump with low pressure might not suit high-demand environments. Check the maximum operating pressure to ensure reliability. Evaluate the materials used; they impact durability and compatibility with various fluids. Corrosive substances require specific materials to avoid degradation.

Noise levels can also be a concern in some settings. A pump that operates quietly may be preferable for sensitive environments. Look at the energy efficiency, as it affects operational costs. While you may want a robust pump, off-the-shelf options might not fit every need perfectly. In these cases, researching custom solutions could be beneficial.

Comparing Different Types of Diaphragm Pumps: Pros and Cons

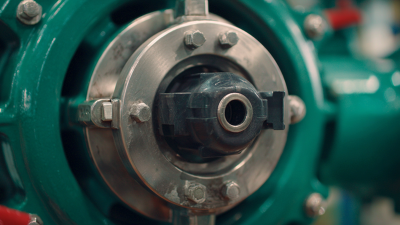

When selecting a diaphragm metering pump, understanding the different types is essential. There are several options available, each with unique advantages and drawbacks. For instance, mechanical diaphragm pumps offer precise flow control. They excel in applications requiring accuracy. However, these pumps may require more maintenance over time. Their complexity can lead to higher operational costs.

On the other hand, hydraulic diaphragm pumps provide minimal wear. They handle harsh fluids effectively. These pumps can operate in challenging environments. Yet, they can be bulkier and heavier. This affects installation options. It's crucial to consider the space you have available.

Another option is the air-operated diaphragm pump. These pumps are known for their simplicity and ease of use. They are portable and can be moved easily. Yet, they may not be as precise as mechanical pumps. You might notice variations in flow rates. Proper analysis of your needs is essential. Each type has unique features. Weighing the pros and cons can lead to better decisions. Test your options before finalizing your choice.

Diaphragm Metering Pumps: Pros and Cons Comparison

Maintenance and Support Considerations for Diaphragm Metering Pumps

When selecting a diaphragm metering pump, maintenance and support are crucial factors. Regular upkeep ensures optimal performance. Neglecting this can lead to inefficiencies and costly downtime. Users often overlook simple tasks, like checking fluid levels or inspecting seals. These checks are vital. They prevent leaks and extend pump life.

Support is also important. Manufacturers typically offer resources like manuals and troubleshooting guides. However, some users struggle with complex instructions. Sometimes, it can be challenging to find the right information. A user might contact support but receive vague responses. This can frustrate the troubleshooting process.

Additionally, consider spare parts availability. Some pumps may require unique components that are hard to find. Users often face delays if parts are out of stock. Familiarity with the pump's design helps in understanding maintenance needs. If a pump is complicated, it may require specialized training for staff. This is often neglected during the initial selection process.

Related Posts

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

Understanding the Importance of Diaphragm Metering Pumps in Precision Fluid Control

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

Understanding the Mechanics of Diaphragm Pumps: The Key to Efficient Fluid Transfer