Blog

How to Choose the Right Diaphragm Chemical Metering Pump for Your Needs

Choosing the right diaphragm chemical metering pump is crucial for achieving optimal performance in various industrial applications. As the demand for precise chemical dosing continues to grow, industry reports indicate that the diaphragm pump market is expected to reach $10 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.7% from 2020 to 2025. This growth can be attributed to the increasing need for accuracy and efficiency in chemical handling processes across sectors such as water treatment, agriculture, and pharmaceuticals.

Expert in the field, Dr. Sarah Johnson, a renowned chemical engineering specialist, emphasizes the importance of selecting the appropriate diaphragm chemical metering pump, stating, “The effectiveness of industrial processes largely depends on the reliability and efficiency of your metering system. Choosing the right diaphragm pump can make all the difference in achieving consistent results.” Her insights highlight that a tailored approach to pump selection can enhance operational efficiency and minimize the risk of chemical waste.

In this guide, we will delve into key factors to consider when selecting a diaphragm chemical metering pump that meets specific needs. With the right knowledge and understanding, operators can ensure their systems are equipped with the most suitable pumping solutions, ultimately leading to better performance and sustainability in their operations.

Understanding Diaphragm Chemical Metering Pumps

Diaphragm chemical metering pumps are essential devices used in various industries to ensure precise chemical dosing. Understanding how these pumps function is crucial for selecting the right one for your specific applications. At their core, diaphragm pumps use a flexible diaphragm to create a seal, allowing for accurate fluid movement without the risk of contamination. The design helps to avoid leaks, making them ideal for handling hazardous or corrosive chemicals.

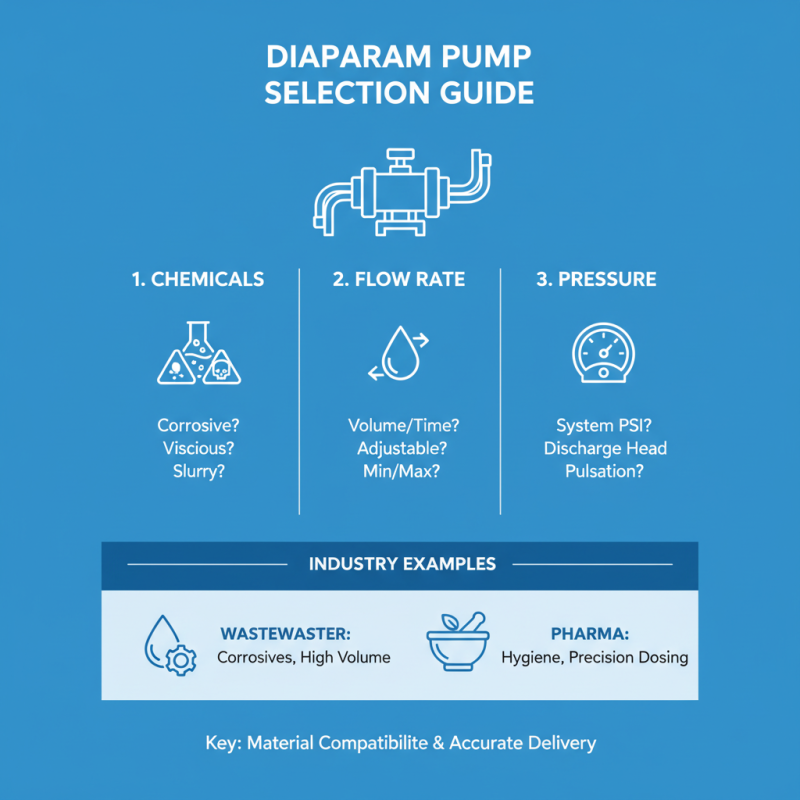

When choosing a diaphragm chemical metering pump, consider the pump's flow rate and pressure capabilities. It's vital to match these specifications with your system requirements to ensure efficient operation. Additionally, take into account the material compatibility, as different chemicals may react differently with the pump materials.

Tips: Always review the pump's operational limits and environmental conditions before making a decision. Installation space and accessibility for maintenance can also influence your choice. Regular maintenance checks are essential to ensure longevity and efficiency, so prioritize pumps that are easy to service. Understanding these elements will help you select the right diaphragm pump tailored to your needs.

How to Choose the Right Diaphragm Chemical Metering Pump for Your Needs

The bar chart below illustrates the common flow rates (in GPH) of diaphragm chemical metering pumps categorized by application suitability. This will aid in understanding the different capacities available when selecting a pump for your specific needs.

Key Factors to Consider When Selecting a Diaphragm Pump

When selecting a diaphragm chemical metering pump, there are several key factors to consider to ensure you choose the right one for your specific application. First and foremost, assess the chemical compatibility of the pump materials with the substances being pumped. Different chemicals have varying levels of corrosiveness, and using a pump that isn't compatible can lead to equipment failure or safety hazards.

Another important factor is the flow rate and pressure requirements of your system. Diaphragm pumps are available in various sizes and capabilities, so it is essential to match the pump’s specifications with your operational needs. Calculate the desired flow rate and maximum pressure to find a pump that meets these parameters effectively.

Tips: Always consult with manufacturers or experts to understand pump performance curves and efficiency ratings. Additionally, consider the ease of maintenance; selecting a pump designed for easy service can save time and reduce downtime in the long run. Finally, evaluate the installation and operational space available, as this can affect the pump's fitting and performance within your system.

How to Choose the Right Diaphragm Chemical Metering Pump for Your Needs - Key Factors to Consider When Selecting a Diaphragm Pump

| Factor | Description | Importance Level |

|---|---|---|

| Flow Rate | The quantity of liquid the pump can deliver over a specific time. | High |

| Pressure Rating | The maximum pressure the pump can handle without failure. | High |

| Chemical Compatibility | The suitability of the pump materials for the chemicals being pumped. | Critical |

| Cycle Frequency | How often the pump cycles in a given time period. | Medium |

| Power Source | The type of power supply needed for the pump operation. | High |

| Size and Weight | The physical dimensions and weight that determine installation feasibility. | Medium |

| Budget | The overall cost of the pump, including installation and maintenance. | High |

| Maintenance Requirements | The frequency and type of maintenance necessary to keep the pump operating efficiently. | Medium |

Different Types of Diaphragm Chemical Metering Pumps

When selecting a diaphragm chemical metering pump, understanding the different types available is crucial to meet your specific needs. Diaphragm pumps can generally be categorized into several types based on their construction and application.

Firstly, there are mechanically actuated diaphragm pumps, which are often used in applications requiring precise dosing. These pumps rely on a mechanical mechanism to displace the diaphragm, allowing for accurate flow rates while handling a variety of chemicals.

Another significant type is the air-operated diaphragm pump, which uses compressed air to drive the diaphragm, providing flexibility in handling different viscosities and fluid types. These are ideal for applications where electricity is not available or where there is a risk of electrical hazards. Additionally, electronic diaphragm pumps offer advanced control systems that can be easily programmed for specific flow rates and dosing schedules, making them suitable for industries requiring high precision and automation. Understanding these variations ensures you choose a pump that aligns with the demands of your specific application.

Evaluating Pump Performance and Specifications

When evaluating the performance and specifications of diaphragm chemical metering pumps, it’s crucial to consider several key factors that influence their efficiency and suitability for specific applications. Firstly, the flow rate and pressure capabilities of the pump should align with the requirements of your operation. Manufacturers typically provide detailed specifications, including maximum flow rates and operating pressures, which are fundamental in ensuring the pump can handle the volume and consistency of the chemical being metered. Understanding the factors affecting flow, such as the viscosity and temperature of the chemicals, is essential for optimizing performance.

Additionally, the material construction of diaphragm pumps plays a significant role in their durability and chemical compatibility. Depending on the chemicals being processed, the diaphragm and the pump housing may need to be made from specific materials to prevent degradation. It is important to examine the chemical resistance ratings and temperature limits of various materials when selecting a pump. Furthermore, assessing the pump's maintenance requirements and simplicity of operation can also enhance productivity and reduce downtime, making reliability and ease of serviceability vital considerations in the selection process.

Application-Specific Requirements for Chemical Metering Pumps

When selecting a diaphragm chemical metering pump, understanding the specific application requirements is crucial for optimal performance. Various industries utilize chemical metering pumps differently, so it's essential to consider the nature of the chemicals involved, flow rates, and pressure requirements. For instance, wastewater treatment facilities may require pumps that handle corrosive substances, while pharmaceutical companies might need pumps that meet strict hygiene standards. This applies not only to the materials used in the pump construction but also to the pump's ability to deliver precise volumes under varying conditions.

Tips: Before making a decision, assess the chemical compatibility of the pump materials with the intended substances. Consult technical datasheets and seek guidance from experienced professionals to ensure the pump can handle specific viscosities and densities of chemicals. Additionally, consider whether you need a manual or automated control feature to enhance operational efficiency.

Another critical aspect is the desired flow rate and pressure. Applications that demand consistent flow, such as food processing or textile manufacturing, will require pumps that can maintain steady output regardless of fluctuations in system pressure. Therefore, performing a thorough analysis of the pump’s specifications against your operational demands will help you avoid costly downtimes and maintenance issues.

Tips: It’s beneficial to simulate the pumping conditions in your application area before finalizing your choice. Take into account the startup and shutdown nuances that could affect overall performance and longevity of the pump.

Related Posts

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

10 Unique Metering Pump Types You Should Know About

-

Innovative Chemical Injection Solutions at the 138th China Import and Export Fair 2025

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency

-

Understanding the Importance of Chemical Metering in Enhancing Industry Efficiency and Safety