Blog

How to Choose the Right Chemical Metering Pump for Your Industry Needs

Selecting the appropriate chemical metering pump for your industry needs is a critical decision that can significantly impact both efficiency and safety in your operations. With a wide array of options available on the market, understanding the unique requirements of your specific applications is essential for making an informed choice. Factors such as flow rate, chemical compatibility, pressure requirements, and the operating environment must all be taken into account. Additionally, considerations like maintenance, ease of installation, and cost-effectiveness play a pivotal role in determining which pump will best serve your needs. This guide aims to provide a comprehensive overview of how to evaluate and select the right chemical metering pump tailored to your business, ensuring optimal performance and reliability in your chemical processes.

Understanding Your Industry Requirements for Chemical Metering Pumps

When choosing a chemical metering pump, it's crucial to first understand the specific requirements of your industry. Different sectors, such as water treatment, pharmaceuticals, and food processing, have unique standards concerning pressure, flow rate, and chemical compatibility. For instance, water treatment facilities may need pumps with a high flow rate to accommodate large volumes of chemicals, while pharmaceutical applications often require precise dosing to adhere to strict regulatory guidelines.

Furthermore, consider the environmental conditions in which the pump will operate. Industries that manage corrosive substances or high temperatures will necessitate pumps made of durable materials resistant to wear and chemical degradation. Additionally, the pump's integration with existing systems should not be overlooked; it is essential to determine whether the pump can be easily incorporated into current processes without requiring extensive modifications. By thoroughly evaluating these factors, you can select a chemical metering pump that not only meets your industry standards but also enhances operational efficiency and safety.

How to Choose the Right Chemical Metering Pump for Your Industry Needs

Key Factors to Consider When Selecting a Chemical Metering Pump

When selecting a chemical metering pump, several key factors must be taken into account to ensure it meets the specific needs of your industry. One of the primary considerations is the pump's accuracy and reliability. Studies show that inaccuracies in chemical dosing can lead to significant operational issues. According to a report from the American Society of Mechanical Engineers, up to 30% of operational costs can arise from inefficient chemical dosing, highlighting the importance of choosing a pump with precise calibration capabilities.

Another essential factor is the pump's compatibility with the chemicals being handled. Many industries, including water treatment and pharmaceuticals, require pumps that can withstand aggressive chemicals without degrading. Data from the Chemical Engineering Magazine indicates that over 40% of chemical metering pump failures result from material incompatibility. Therefore, it's crucial to evaluate the materials used in the pump's construction, ensuring they align with the chemical properties to avoid costly downtime and safety hazards. Finally, consider the pump's operational noise level, especially in environments where quiet operation is essential, as this can significantly enhance the overall work environment.

Types of Chemical Metering Pumps and Their Applications

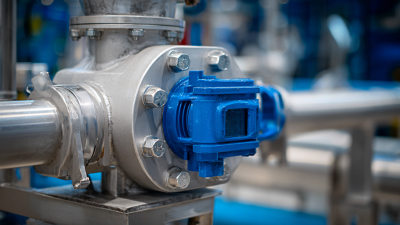

When selecting a chemical metering pump, understanding the different types and their specific applications is crucial. The most common types include diaphragm pumps, gear pumps, peristaltic pumps, and screw pumps. Diaphragm pumps are often used in water treatment applications due to their ability to handle corrosive chemicals at high pressures. Gear pumps are ideal for industries that require precise flow rates, while peristaltic pumps are favored in biotechnology for their gentle handling of delicate fluids.

When selecting a chemical metering pump, understanding the different types and their specific applications is crucial. The most common types include diaphragm pumps, gear pumps, peristaltic pumps, and screw pumps. Diaphragm pumps are often used in water treatment applications due to their ability to handle corrosive chemicals at high pressures. Gear pumps are ideal for industries that require precise flow rates, while peristaltic pumps are favored in biotechnology for their gentle handling of delicate fluids.

Tips for choosing the right pump include considering the chemical compatibility with your materials, the required flow rate, and the precision needed for your application. Additionally, assess the operational environment, as some pumps are better suited for high-temperature or abrasive conditions than others.

It's also essential to evaluate the ease of maintenance and reliability of the pump. This can significantly impact operational efficiency and costs in the long run. Regular maintenance checks and choosing pumps with a good track record can minimize downtime and enhance productivity in your operations.

Evaluating Pump Performance and Specifications

When selecting a chemical metering pump for industrial applications, evaluating pump performance and specifications is critical to ensure optimal efficiency and reliability. According to the "2022 Chemical Pump Market Analysis" report by MarketsandMarkets, the demand for precision metering pumps has surged, with an expected compound annual growth rate (CAGR) of 5.8% from 2022 to 2027. This growth is primarily driven by industries such as water treatment, oil and gas, and food processing, where accurate chemical dosing is essential for compliance and safety.

Key performance metrics to assess include flow rate, pressure rating, and material compatibility. For instance, a high-performance pump should provide a consistent flow rate, often ranging from 0.1 to 500 gallons per hour, depending on the application needs. Furthermore, compatibility with various chemicals, including corrosive substances, necessitates pumps made from materials like PVDF or stainless steel. A recent study published in the Journal of Chemical Engineering highlighted that using the wrong materials can lead to pump failure, resulting in costly downtimes. Thus, understanding the specifications and operational limits of a pump is imperative for selecting the right equipment aligned with industry demands.

Budgeting and Maintenance for Chemical Metering Pump Selection

When selecting a chemical metering pump, budgeting plays a crucial role in ensuring that your investment aligns with both operational needs and financial constraints. According to industry reports, the price range for chemical metering pumps can vary significantly, with high-end models reaching costs upwards of several thousand dollars, while more budget-friendly options might start around $500. Understanding the specific requirements of your industry, such as flow rate, pressure, and the type of chemicals being handled, is essential in avoiding overspending on unnecessary features.

In addition to budgeting, proper maintenance of chemical metering pumps cannot be overlooked. Regular servicing can prolong the lifespan of the pump and prevent costly downtime. Reports indicate that pumps should undergo routine inspections to check for wear and tear, as well as operational efficiency. Maintenance practices might include checking seals and bearings, cleaning filters, and ensuring that the suction lines are clear. Adopting a structured maintenance schedule can lead to cost savings in the long run, as neglecting pump upkeep often results in more severe and expensive repairs.

Related Posts

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

How to Choose the Right Industrial Pumps for Your Manufacturing Needs