Blog

Top Chemical Pump Innovations to Watch for in 2025

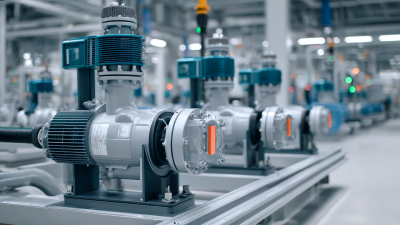

The world of chemical pumps is on the brink of significant transformation as we approach 2025. This evolution is driven by the need for greater efficiency, sustainability, and adaptability in various industries, from manufacturing to environmental management. Innovations in chemical pump technology are not only enhancing operational capabilities but also addressing critical challenges such as energy consumption and material compatibility. As companies strive to meet regulatory requirements and customer demands, the latest advancements promise to revolutionize how chemical fluids are transported, processed, and utilized.

Amidst these advancements, we are witnessing a myriad of emerging technologies that are set to redefine the standards in chemical pumping. From smart monitoring systems that utilize IoT capabilities to advanced materials designed to withstand harsh chemical environments, the innovations in chemical pump design and functionality are expanding the horizons for industrial applications. These developments are crucial in promoting efficient resource use and minimizing downtime, ultimately leading to increased productivity and reduced operational costs. As we delve into the key innovations on the horizon, it is essential to explore how these trends will shape the landscape of chemical processing in the near future.

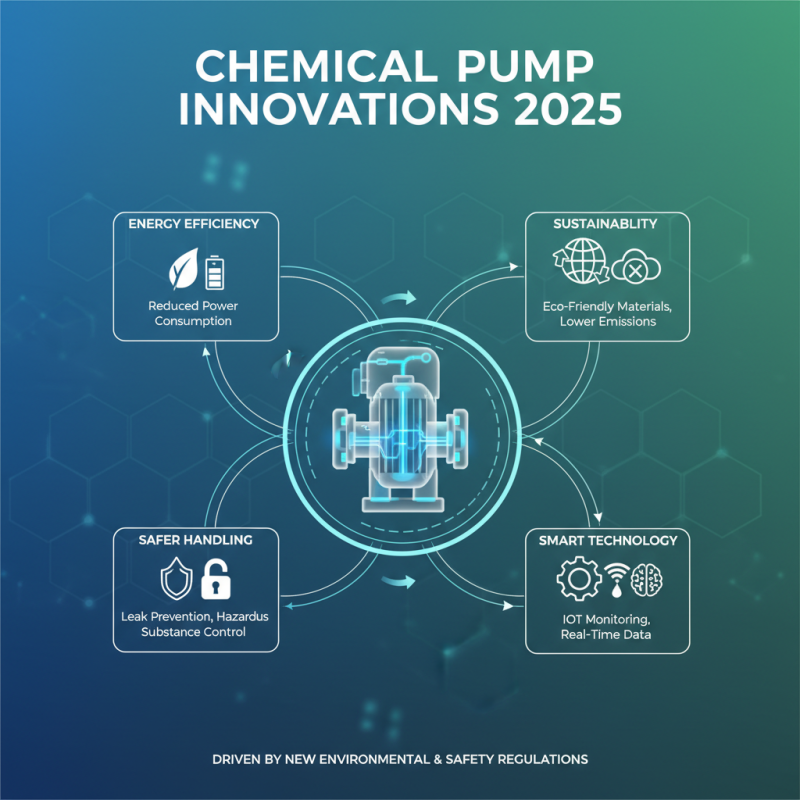

Emerging Trends in Chemical Pump Design for 2025

As we look towards 2025, the landscape of chemical pump design is evolving rapidly, driven by advancements in technology and a greater emphasis on sustainability. The global chemical pump market is projected to grow at a CAGR of 5.2% from 2021 to 2026, reflecting the increasing demand for efficient and innovative pumping solutions. One of the emerging trends is the integration of smart technologies, such as IoT and AI, into pump systems. These technologies facilitate predictive maintenance, allowing operators to monitor performance in real-time and reduce downtime, ultimately enhancing productivity.

Another significant innovation in chemical pump design is the development of eco-friendly materials and energy-efficient motors. With growing environmental regulations and corporate sustainability goals, manufacturers are focusing on creating pumps that minimize their carbon footprint. According to a recent industry report, pumps designed with recyclable materials or those that operate on alternative energy sources, like solar power, have seen a rise in adoption, particularly among industries with stringent environmental standards.

Tips for organizations considering upgrades in their pumping systems:

- Invest in training for personnel to effectively utilize new technologies.

- Ensure regular maintenance to prolong the lifespan of equipment.

- Conduct thorough assessments of their specific pumping needs to identify the most suitable innovations tailored to their operational goals.

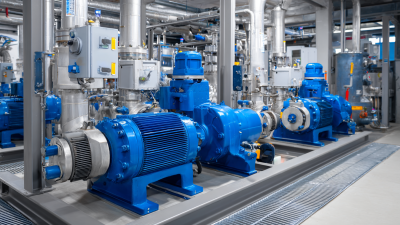

Advancements in Materials for Enhanced Durability and Safety

In recent years, the chemical pump industry has experienced significant advancements driven by innovations in materials that enhance durability and safety. According to a report by Grand View Research, the global chemical pump market is projected to reach USD 10.32 billion by 2025, largely fueled by the increasing use of advanced materials like titanium, carbon fiber, and high-performance plastics. These materials are not only corrosion-resistant but also capable of withstanding extreme temperatures and pressures, making them ideal for demanding chemical processing environments.

A notable trend in this arena is the development of composite materials that combine the benefits of metals and polymers. These composites provide superior strength-to-weight ratios and resist chemical degradation, thereby extending the life cycle of pumps while reducing maintenance costs. A study by the American Institute of Chemical Engineers found that pumps made from advanced composite materials can outperform traditional metal pumps in harsh environments, reducing failure rates by up to 25%. Such innovations not only improve operational efficiency but also enhance safety by minimizing risks of leaks and system failures, crucial in industries ranging from pharmaceuticals to water treatment.

The emphasis on safety is further reflected in the integration of smart technologies within pump systems. Advanced monitoring and control technologies can detect performance deviations in real time, allowing for proactive maintenance and reducing the chances of hazardous incidents. As the demand for more resilient and safer chemical handling systems grows, these material advancements will remain at the forefront of the industry's evolution, setting a new standard in pump design and operation.

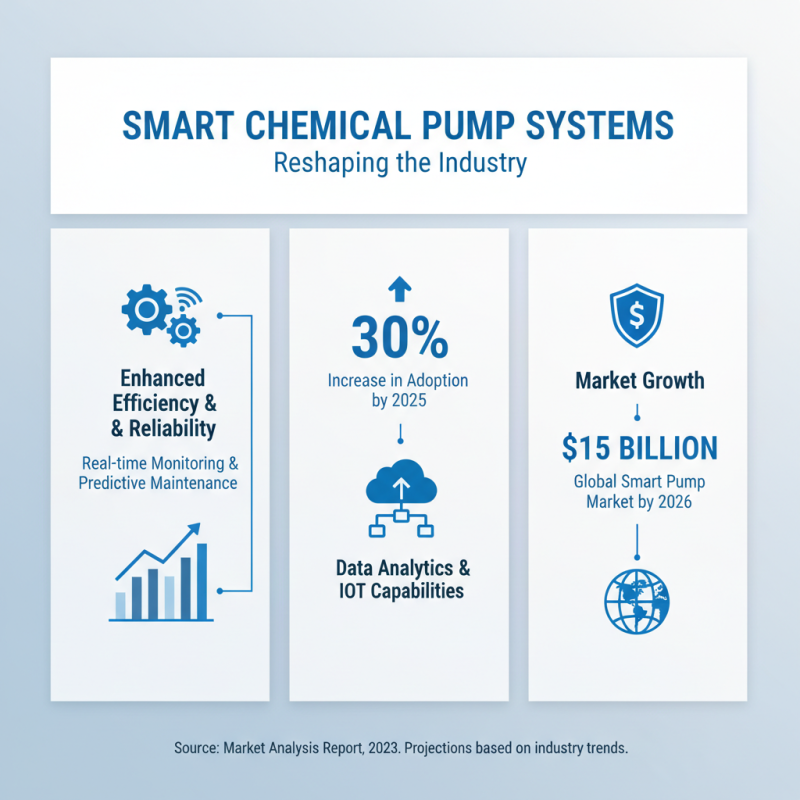

Integration of Smart Technology in Chemical Pump Systems

The integration of smart technology into chemical pump systems is reshaping the industry landscape, paving the way for enhanced efficiency, reliability, and safety. By 2025, it is projected that the adoption of smart technologies in chemical pump systems will increase by over 30%, driven by the need for real-time monitoring and predictive maintenance. According to a recent market analysis report, the global smart pump market is expected to reach $15 billion by 2026, indicating a robust growth rate as companies look to leverage data analytics and IoT capabilities in their pumping operations.

Smart technology in chemical pumps facilitates the collection and analysis of operational data, enabling companies to optimize pump performance and minimize downtime. For instance, real-time data allows for proactive maintenance schedules, reducing the risk of unexpected failures, which can be costly in terms of both time and resources. Reports suggest that businesses implementing smart pump systems can achieve up to a 20% reduction in operational costs while also improving energy efficiency by at least 15%. Furthermore, enhanced monitoring capabilities contribute to better compliance with safety and environmental regulations, addressing critical concerns in the chemical industry.

As we move towards 2025, the convergence of smart technology with chemical pump systems represents a fundamental shift towards automation and intelligence, allowing industries to meet increasing demands while improving resource management and operational sustainability.

Energy Efficiency Improvements: Reducing Operational Costs

As the chemical processing industry increasingly focuses on sustainability, energy efficiency is becoming a crucial factor in the design and operation of chemical pumps. A recent report from the Department of Energy indicates that optimizing energy consumption in chemical processes can lead to a reduction in operational costs by up to 20%. Innovations in pump technology, including variable frequency drives (VFDs) and advanced materials, are setting new standards for energy efficiency. These advancements allow for better flow control and reduced energy use, catering to the industry’s growing demand for cost-effective and environmentally friendly solutions.

Moreover, according to a study by the Global Pumps Industry Association, energy-efficient pumps can significantly decrease the carbon footprint of chemical plants. By implementing next-generation pump systems, companies can achieve efficiency gains that translate to substantial savings over time. For instance, systems designed with smart sensors and IoT capabilities are enabling real-time monitoring of pump performance, which helps in identifying inefficiencies and optimizing operations. The transition to these innovative solutions not only enhances productivity but also aligns with regulatory pressures for greener engineering practices, ensuring that businesses remain competitive in a rapidly evolving landscape.

Top Chemical Pump Innovations to Watch for in 2025 - Energy Efficiency Improvements: Reducing Operational Costs

| Innovation Type | Description | Projected Efficiency Gain (%) | Expected Cost Reduction (%) |

|---|---|---|---|

| Smart Monitoring Systems | Real-time performance tracking for optimization. | 15 | 10 |

| Advanced Materials | Use of lightweight and corrosion-resistant materials. | 12 | 8 |

| Variable Frequency Drives (VFD) | Energy-efficient speed control for pump operations. | 20 | 15 |

| Self-Priming Pumps | Enhanced design for energy saving during startup. | 10 | 5 |

| Automated Pump Control | AI-driven systems for optimal performance management. | 18 | 12 |

Regulatory Changes Impacting Chemical Pump Innovations in 2025

As we approach 2025, regulatory changes are poised to significantly influence innovations in the chemical pump industry. New environmental regulations are driving manufacturers to develop pumps that are more energy-efficient and sustainable. These requirements not only target emissions reductions but also mandate safer handling of hazardous substances, prompting innovations that enhance leak prevention and improve materials compliance with stricter safety standards. The focus is shifting from traditional designs to advanced technologies, such as smart pumps that utilize IoT capabilities to monitor real-time performance and environmental impact.

Additionally, changes in industry standards related to the use of non-toxic materials are fostering the development of chemical pumps that minimize harmful effects on both operators and ecosystems. This evolution is likely to lead to a surge in the adoption of eco-friendly materials and coatings that resist corrosion and chemical degradation. Manufacturers are increasingly collaborating with regulatory bodies to ensure compliance, which fosters innovation while meeting the expectations set forth by new regulations. As a result, the industry is not only responding to legal requirements but also positioning itself to meet the growing demand from environmentally conscious consumers and industries.

Related Posts

-

Understanding the Role of Chemical Feed Pumps in Modern Industrial Applications

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

Understanding the Importance of Chemical Pumps in Modern Industrial Processes

-

Understanding the Role of Chemical Metering Pumps in Sustainable Industry Practices

-

How to Choose the Right Chemical Metering Pump for Your Industry Needs

-

2025 Guide to Choosing the Best Chemical Injection Pumps for Your Needs