Blog

Understanding the Role of Chemical Metering Pumps in Sustainable Industry Practices

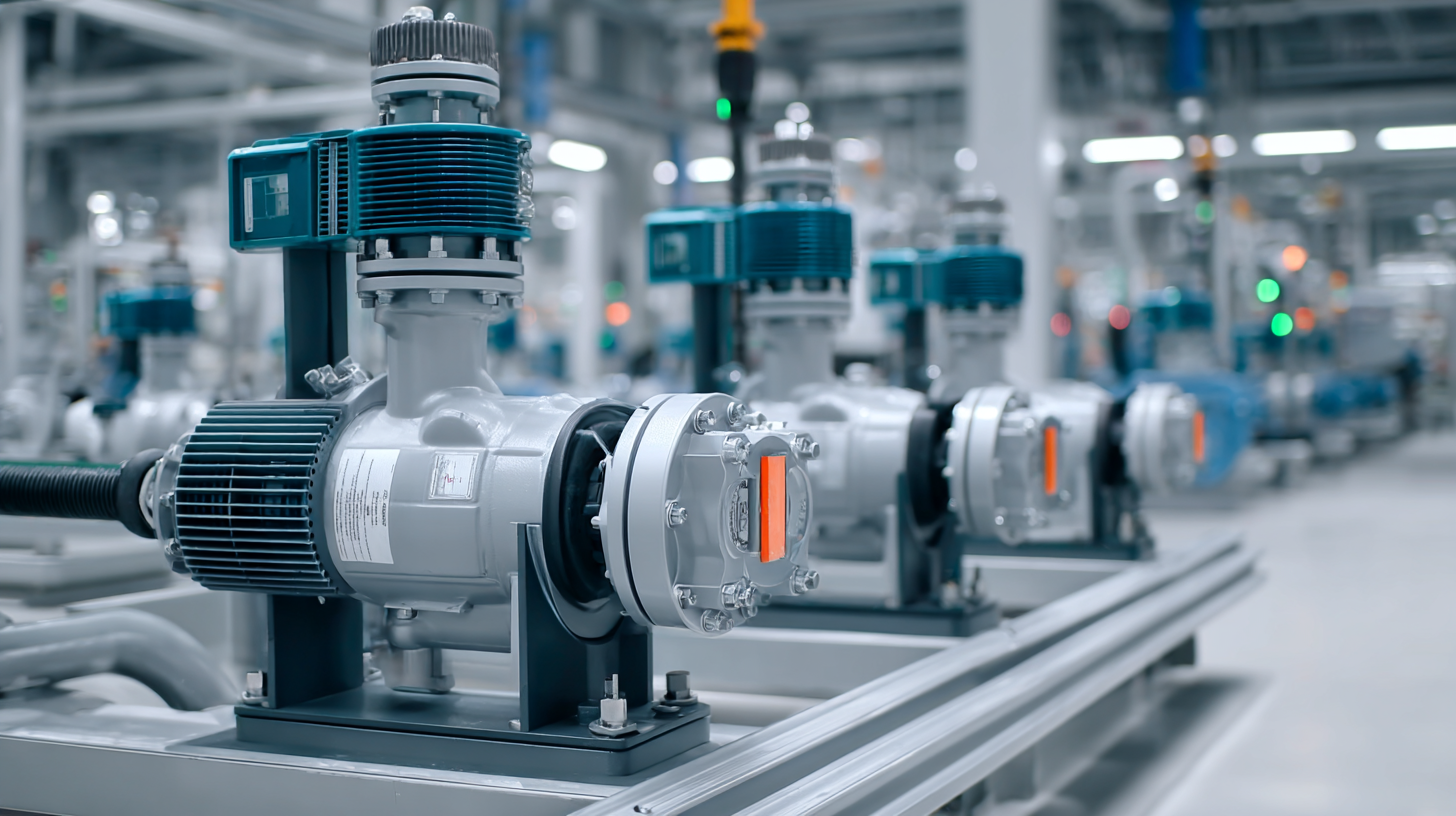

In the pursuit of sustainable industrial practices, the role of the chemical metering pump has emerged as a pivotal element in enhancing operational efficiency and minimizing environmental impact. According to a report by MarketsandMarkets, the global chemical metering pump market is projected to reach USD 6.5 billion by 2025, growing at a CAGR of 6.2% from 2020, underlining the increasing adoption of precision dosing technologies across various sectors. These pumps are essential for accurately dispensing chemicals at required rates, which not only optimizes resource usage but also ensures compliance with stringent regulatory standards on waste management and emissions. As industries strive to balance productivity and sustainability, the chemical metering pump is becoming integral to innovative solutions that support green initiatives and promote responsible resource management.

The Essential Functions of Chemical Metering Pumps in Sustainable Operations

Chemical metering pumps play a vital role in sustainable operations across various industries. These devices precisely deliver chemicals in controlled quantities, ensuring optimal efficiency and minimal waste. As the metering pumps market is projected to reach USD 8.5 billion by 2028, businesses are increasingly recognizing the importance of these pumps in enhancing environmental responsibility while maintaining operational effectiveness. By accurately regulating the dosages of chemicals, companies can reduce their ecological footprint and contribute to greener industrial practices.

Tips for optimizing the use of chemical metering pumps include regularly monitoring pump calibration to avoid over or under-dosing, which can lead to wasted resources and potential environmental harm. Additionally, selecting the appropriate material for pump components can significantly enhance durability and reduce maintenance costs, promoting a more sustainable operation in the long run.

Incorporating advanced technologies such as smart sensors can further refine the capabilities of metering pumps, allowing for real-time adjustments based on operational data. This kind of integration not only optimizes chemical usage but also supports the broader goal of sustainable industrial practices, making chemical metering pumps essential tools for environmentally conscious businesses in today's evolving market landscape.

Understanding the Role of Chemical Metering Pumps in Sustainable Industry Practices

Evaluating the Efficiency of Metering Pumps for Eco-Friendly Processes

Chemical metering pumps play a vital role in enhancing the efficiency of eco-friendly industrial processes. By accurately delivering precise amounts of chemicals, these pumps minimize waste and ensure the optimal use of resources. This precision not only reduces excess chemical usage but also limits environmental impact, making them essential tools for industries aiming to adopt sustainable practices. Their ability to operate under varying conditions allows for flexibility in applications, thereby supporting diverse eco-friendly initiatives.

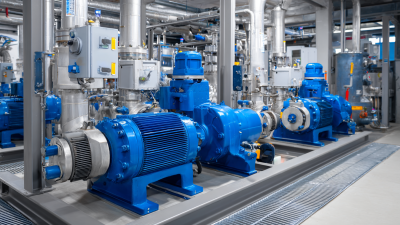

Moreover, metering pumps contribute to energy efficiency by reducing the need for additional processing and minimizing downtime. Advanced technologies in metering pumps, such as variable speed drives and smart control systems, enable real-time monitoring and adjustment of chemical dosing. This adaptability fosters greater control over processes, ensuring that the right amounts of chemicals are used only when necessary. As industries continue to strive for sustainability, the efficiency of metering pumps becomes increasingly critical in facilitating greener practices and meeting regulatory standards.

Innovations in Chemical Metering Pump Technology for Sustainable Industries

Innovations in chemical metering pump technology are becoming increasingly vital in promoting sustainability across various industries. The adoption of smart and eco-friendly dosing systems not only enhances efficiency but also reduces environmental impact by minimizing chemical waste and ensuring precise dosages. With advancements in automation and real-time monitoring, these pumps can adjust their performance based on current operational demands, leading to a more effective use of resources.

As industries face growing challenges related to water management, the role of metering pumps becomes even more critical. Emerging trends, such as decentralized infrastructure and sustainable water treatment methods, are reshaping the landscape of resource utilization. The metering pump market is projected to significantly grow, reflecting a heightened focus on sustainable practices. Companies are increasingly investing in innovative pump solutions that contribute to water security, aiming to align with environmental goals while meeting production demands efficiently.

Best Practices for Implementing Metering Pumps in Green Manufacturing

In the pursuit of sustainable manufacturing, the integration of chemical metering pumps plays a crucial role in enhancing efficiency and reducing waste. According to a report by the U.S. Environmental Protection Agency (EPA), industries that incorporate advanced metering technologies can decrease chemical consumption by up to 30%, significantly minimizing their environmental footprint. To achieve these benefits, manufacturers should prioritize precision in pump selection, ensuring that the pump’s specifications align with the exact requirements of their processes. This meticulous approach not only conserves resources but also optimizes production quality.

Moreover, regular maintenance of metering pumps is essential for sustainable practices. A study conducted by the international organization, Water Environment Federation, highlights that proactive maintenance can lead to an impressive reduction in operational costs by nearly 15% over time. Implementing a routine check-up schedule not only prolongs the life of the pumps but also ensures that they operate at maximum efficiency, further supporting green initiatives. Manufacturers should also consider innovative metering technologies such as flow monitoring and automated control systems, which enhance accuracy and responsiveness in chemical dosing, thereby minimizing overuse and spills in their operations.

Case Studies: Successful Utilization of Metering Pumps in Sustainable Projects

Chemical metering pumps play a crucial role in advancing sustainable industry practices by ensuring precise and efficient chemical dosing in various applications. This precision is particularly vital in projects focused on environmental conservation and energy efficiency. In metropolitan regions like Sydney and Melbourne, innovative implementations of metering pumps have shown significant reductions in chemical waste and improvements in resource utilization, aligning with the climate action goals of a global network of megacities.

Case studies from these Australian cities reveal how chemical metering pumps have been effectively integrated into water treatment facilities and industrial processes. For instance, Sydney's initiatives to enhance water quality control through automated dosing systems showcase the capacity of metering pumps to optimize chemical usage while minimizing environmental impact. Similarly, Melbourne's sustainable industrial projects demonstrate the adaptability of these pumps in managing corrosive chemicals, thereby promoting safe and eco-friendly operations. These examples highlight the essential contribution of metering pumps in driving sustainability efforts across various sectors.

Related Posts

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

Understanding the Importance of Chemical Pumps in Modern Industrial Processes

-

Understanding the Role of Chemical Feed Pumps in Modern Industrial Applications

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

How to Choose the Right Chemical Metering Pump for Your Industry Needs

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers