Blog

2026 Best Chemical Injection Techniques for Effective Results?

Chemical injection plays a crucial role in various industries. It allows for precise delivery of substances that enhance processes or mitigate issues. The effectiveness of chemical injection depends on the techniques used. Many methods exist, but not all guarantee optimal results.

In the pursuit of efficiency, it’s essential to recognize the potential pitfalls. Poorly executed chemical injection can lead to waste or safety hazards. Selecting the right technique is vital. It ensures effective results and minimizes risks. The diversity in chemical properties means there’s no one-size-fits-all solution.

Exploring the best practices for chemical injection can enhance productivity. Each method offers different benefits and challenges. By understanding these nuances, industries can improve their chemical injection strategies. Continuous improvement in this area is necessary for achieving effective outcomes.

Overview of Chemical Injection Techniques in 2026

In 2026, chemical injection techniques continue to evolve significantly. The focus has shifted towards efficiency and environmental safety. Research suggests that over 65% of industries now prioritize eco-friendly methods. The use of automated systems has increased, enhancing accuracy and reducing waste.

Current data indicates that pneumatic injection systems are gaining popularity. They utilise compressed air to inject chemicals, ensuring precision. However, users report challenges in maintaining these systems. Regular maintenance is crucial to prevent failures. An industry survey highlighted that nearly 30% of users experienced downtime due to malfunctioning equipment.

Moreover, newer formulations of chemicals are being developed, allowing for better results with lower volumes. Yet, the costs for these advanced solutions can be prohibitive. Some companies remain hesitant to invest, fearing insufficient return on investment. This hesitation stems from previous investments that did not yield expected improvements. Balancing innovation and cost-effectiveness is a challenge for many in the field.

2026 Best Chemical Injection Techniques for Effective Results

| Technique | Application | Efficiency (%) | Cost per Unit ($) | Notes |

|---|---|---|---|---|

| Direct Injection | Industrial water treatment | 95 | 0.30 | Highly effective for large volumes |

| Pulse Injection | Oil recovery | 90 | 0.45 | Reduces chemical waste |

| Batch Injection | Chemical processing | 85 | 0.50 | Cost-effective for small batches |

| Continuous Injection | Pipeline cleaning | 92 | 0.40 | Maintains flow efficiency |

| Micro-injection | Pharmaceuticals | 98 | 0.60 | Precise dosage delivery |

Essential Factors Influencing Chemical Injection Effectiveness

Chemical injection is a crucial method used across various industries. The effectiveness of this technique depends on several key factors. Understanding these factors can enhance results and optimize operations.

One essential factor is the precise formulation of the chemicals used. The concentration and compatibility of the chemicals significantly affect performance. Using the wrong mixture can lead to subpar results. For example, incorrect dilution rates might reduce efficacy or cause undesired reactions. Operators often overlook these details, leading to inconsistent outcomes.

Another important aspect is the timing of the injection. Injecting chemicals at the wrong moment can diminish their effectiveness. Timing affects how well the chemicals interact with the target materials. Some operators may rush this step, neglecting proper scheduling. This can result in wasted resources and failed objectives.

Monitoring environmental conditions is also vital; temperature and pressure can influence the performance of chemical injections. Ignoring these conditions can be a costly mistake for many projects.

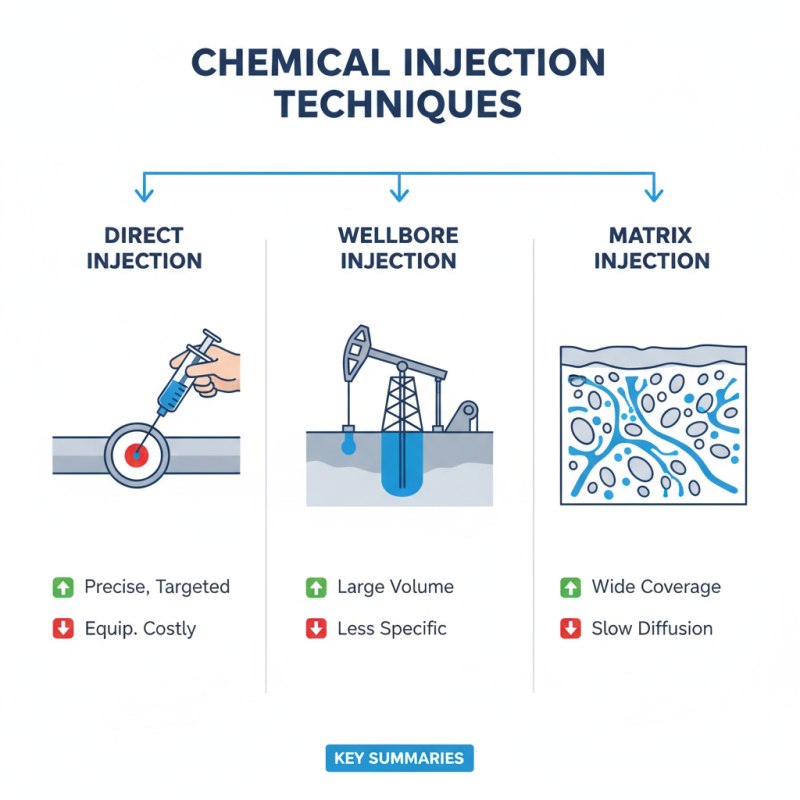

Comparative Analysis of Injection Methods: Pros and Cons

Chemical injection techniques vary widely, each with unique advantages and drawbacks. Some methods are highly effective but come with challenges. For example, the direct injection method is precise and allows for targeted application. However, it often requires specialized equipment, which can be costly.

On the other hand, the misting technique provides broader coverage. It is easier to implement and less expensive. Yet, achieving the same level of precision as direct injection can be difficult. Overspray can lead to wasted resources. Balancing effectiveness with cost is a common challenge.

Another method, the foaming technique, offers good coverage and penetration. It can be ideal for hard-to-reach areas. However, it may not always provide the desired chemical concentration. Each method has its purpose, but no single technique is without flaws. Reflecting on these aspects is crucial for making informed decisions.

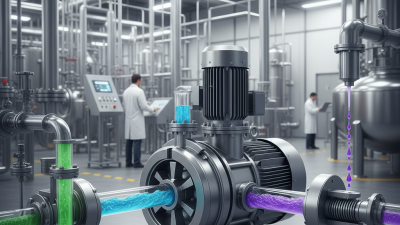

Innovative Technologies Enhancing Chemical Injection Performance

Chemical injection plays a crucial role in various industries. Innovative technologies have emerged, significantly enhancing performance. One notable advancement is real-time monitoring systems. These systems provide instant feedback on injection rates and chemical concentrations. Such precision can prevent over or under-injection, which often leads to inefficiencies.

Incorporating AI algorithms can further optimize these processes. Machine learning can analyze data patterns. With this information, systems can adjust injections automatically. However, the complexity of these technologies can pose challenges. Operators may need extensive training to fully understand the systems. Lack of training can lead to errors.

Moreover, the integration of smart sensors can improve safety. These sensors can detect leaks or malfunctions early. Early detection is key to minimizing risks and costs. Yet, not all facilities have the resources to implement these technologies. This raises questions about accessibility and feasibility. As industries evolve, finding the balance between innovation and practicality becomes essential.

Best Practices for Implementing Chemical Injection Techniques

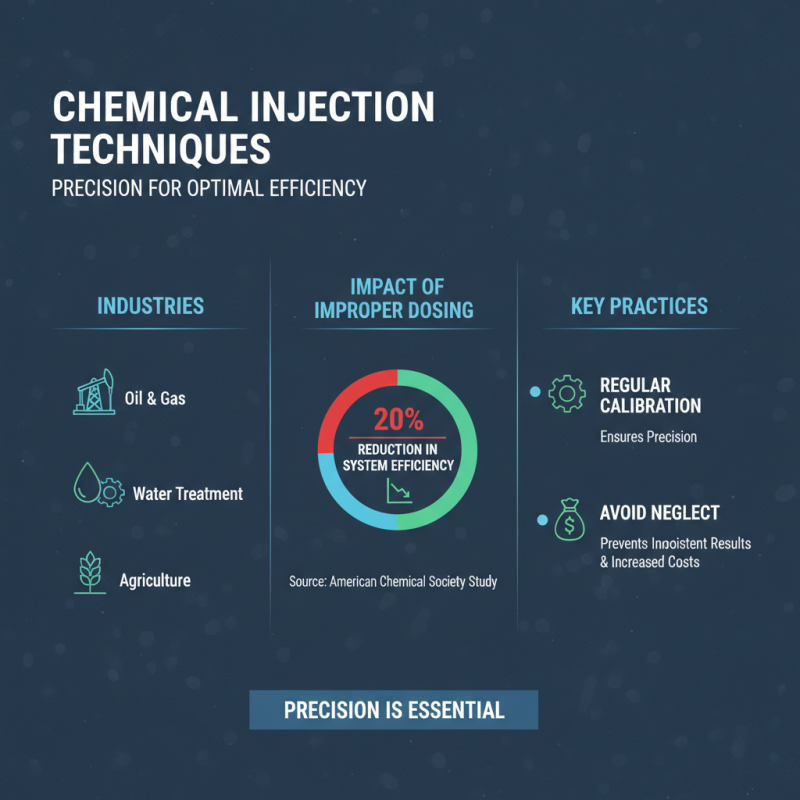

Effective implementation of chemical injection techniques is vital in industries such as oil and gas, water treatment, and agriculture. According to a study by the American Chemical Society, improper chemical dosing can lead to a 20% reduction in system efficiency. Ensuring precision is essential. It's important to calibrate injection pumps regularly. Neglecting this step can lead to inconsistent results and increased costs.

Monitoring chemical concentrations in real-time can prevent costly over- or under-injection. A report by the World Economic Forum stated that adopting real-time monitoring can optimize chemical usage by 30%. However, integrating this technology may pose challenges. Staff may require additional training, and initial costs can be high. Investing in human resources and technology is crucial. Regular training sessions and maintenance checks can help ensure optimal performance.

Field data shows that implementing automated systems can reduce human error by up to 40%. Yet, many organizations still manually handle injections, risking inaccuracies. This area requires reflection and improvement. Understanding the consequences of improper chemical management is key. Focusing on continual improvement will lead to better outcomes in the long run. Balancing cost, efficiency, and safety is a common struggle for many. It’s a journey worth taking for effective results.

Related Posts

-

Innovative Chemical Injection Solutions at the 138th China Import and Export Fair 2025

-

What is a Chemical Pump and How Does it Work?

-

How to Choose the Right Commercial Pump for Your Business Needs

-

10 Unique Metering Pump Types You Should Know About

-

What is an Industrial Pump? Understanding Types, Uses, and Benefits

-

5 Best Practices for Choosing the Right Chemical Feed Pump