Blog

10 Best Chemical Injection Pumps for Optimal Performance?

Chemical injection pumps play a crucial role in various industries, ensuring optimal performance in chemical delivery systems. Renowned expert Dr. Emily Carter stated, "The right pump can significantly enhance efficiency and reduce costs." This highlights the importance of selecting the best chemical injection pumps for specific applications.

Choosing chemical injection pumps requires careful consideration of several factors. Pump capacity, accuracy, and compatibility are vital. Many industries use these pumps for precise chemical handling, from water treatment to oil and gas applications. However, not all pumps perform equally. Some may face issues with reliability or maintenance, leading to inefficiencies.

In the quest for optimal performance, users often overlook essential details. For instance, pump installation can affect operation. Regular maintenance is also critical; neglect can result in poor performance. Understanding these nuances can help users make better choices. Ultimately, selecting the right chemical injection pumps involves weighing various factors and reflecting on past experiences.

10 Best Chemical Injection Pumps for Optimal Performance Overview

Chemical injection pumps play a vital role in various industries, including water treatment, oil and gas, and agriculture. These pumps facilitate the precise delivery of chemicals, ensuring optimal performance and safety. According to industry reports, chemical injection pumps can enhance the overall efficiency of operations by up to 25% when chosen wisely.

Selecting the right pump requires understanding specific needs. For instance, pumps rated for high chemical compatibility are essential. A recent survey indicated that improper pump selection leads to reduced lifespan and costly maintenance issues. It’s crucial to evaluate flow rates, pressure ratings, and materials of construction. Many users overlook the importance of routine maintenance, which can significantly impact performance over time.

Investing in effective chemical injection technology can reduce operational risks. However, the initial cost can be daunting for some businesses. Yet, the return on investment can be substantial. Clients have reported savings due to fewer repairs and improved chemical handling efficiency. Every company should reflect on its unique requirements to avoid common pitfalls in pump selection.

Key Features to Consider When Choosing Chemical Injection Pumps

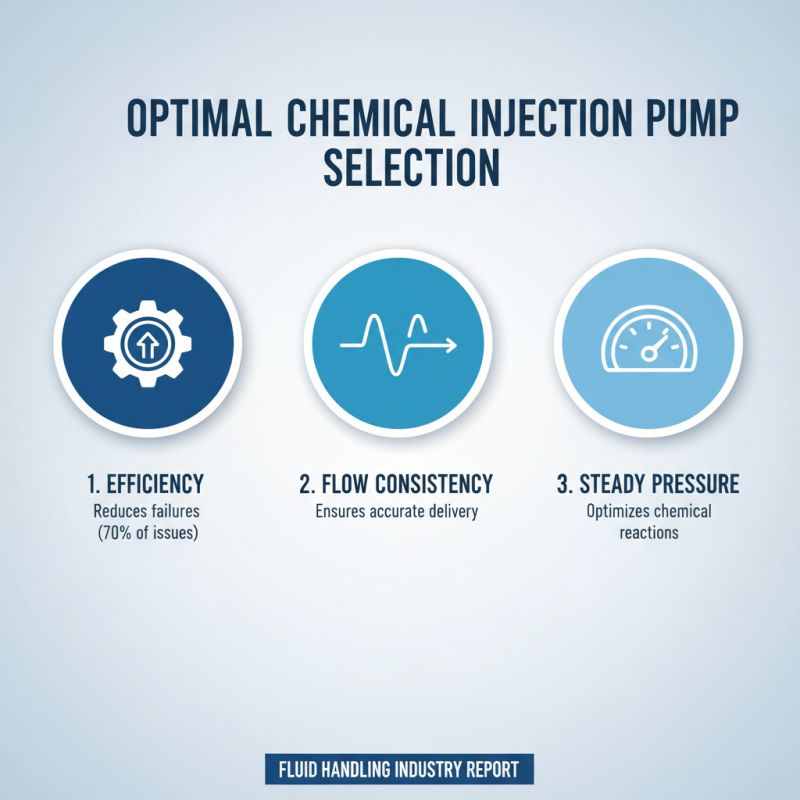

When choosing a chemical injection pump, it is vital to focus on key features that affect performance. Efficiency is a main consideration. A report by the Fluid Handling Industry highlighted that 70% of chemical injection failures are due to inefficient pumping systems. Selecting pumps with good flow consistency can mitigate this issue. Look for units capable of steady pressure maintenance. These factors ensure that chemicals are delivered accurately for optimal reactions.

Material compatibility is also crucial. Depending on the chemicals used, certain materials can degrade quickly, leading to frequent replacements. A study from the Chemical Engineering Journal noted that pumps made from robust materials have a lifespan 40% longer than those with inferior components. Always verify that the pump can handle the chemical's corrosiveness and temperature.

Lastly, ease of maintenance cannot be overlooked. Maintenance processes often contribute significantly to downtime. A survey revealed that over 25% of companies face extended delays due to complex servicing procedures. Choosing a pump with user-friendly features can help reduce these instances. Efficient designs not only save time but also minimize errors during maintenance. Making informed choices in these areas can drive performance.

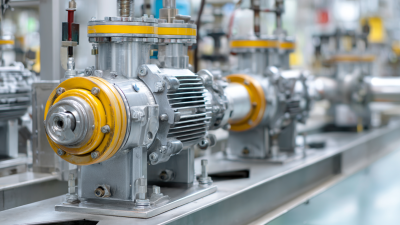

Top 5 Chemical Injection Pumps for High-Pressure Applications

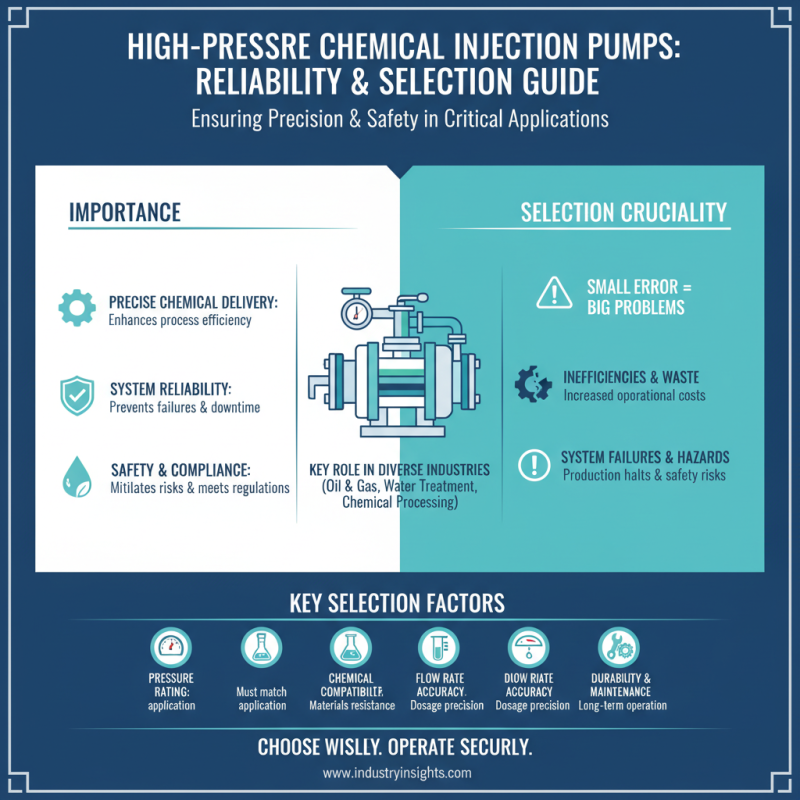

When it comes to high-pressure applications, reliability is crucial. Chemical injection pumps play a vital role in various industries. They ensure precise delivery of chemicals to enhance processes and maintain safety. Many options exist, but selecting the right one can be challenging. A small error in selection can lead to inefficiencies or even system failures.

Consider pumps designed for high pressure. They often feature robust materials that resist corrosion and wear. High-pressure pumps are built to handle demanding environments. It’s essential to assess the flow rate and pressure specifications. Even a minor mistake here can disrupt operations. Additionally, the ease of maintenance should not be overlooked. Complicated designs may lead to downtime.

Always evaluate your specific needs before purchasing. Not all pumps suit every application. Think about the chemical properties involved. Some may require special seals or additional safety features. There’s no one-size-fits-all answer in this field. Make a list of priorities. This will guide you toward making a more informed choice. However, even the best options can have drawbacks. Continuous improvement is key to overcoming these challenges.

Performance Metrics: Flow Rate and Consistency in Chemical Injection Pumps

When selecting chemical injection pumps, flow rate and consistency are critical metrics. Flow rate refers to the volume of chemical delivered over time. A pump that delivers a consistent flow rate ensures more accurate dosing. In applications like water treatment, precise dosing can impact overall efficiency. A fluctuation in flow can lead to imbalances in chemical concentrations, which may result in less effective treatment.

Consistency in performance is achieved through quality construction. Durability often contributes to long-term performance. However, some pumps may struggle under varying temperatures or pressures. Monitoring system conditions is essential to maintain optimal function. Engineers must regularly evaluate how environmental factors affect flow. A pump might work well in lab conditions but perform poorly in the field.

Not all pumps are created equal, and this is evident in their maintenance needs. Some models require frequent recalibration to ensure accurate flow rates. This can be time-consuming and costly. Understanding the specific requirements of the system can guide the selection process. It’s vital to consider both the intended use and the possible challenges of the installation site.

Maintenance Best Practices for Longevity of Chemical Injection Pumps

Maintaining chemical injection pumps is crucial for their longevity and optimal performance. Regular inspection of seals and gaskets helps prevent leaks. A small leak can lead to loss of efficiency. Check the pump's flow rates periodically. If you notice fluctuations, it could signal potential issues. Keeping a log of these readings aids in analysis.

Proper cleaning is often overlooked. Residues can build up and affect functionality. Use appropriate cleaning agents designed for your pump’s material. Don’t forget to lubricate moving parts regularly. This reduces wear and tear, extending the pump's lifespan. Consider environmental factors, too. High temperatures or corrosive substances can damage internal components over time.

Finally, training your staff on pump operation can improve longevity. They should know how to handle common issues. A knowledgeable team can spot problems earlier. Documenting maintenance activities is essential for tracking performance over time. This reflection leads to better practices. Neglecting these steps may result in costly repairs or downtime. Each small detail matters significantly in preserving your pump's efficiency.

Related Posts

-

2025 How to Choose the Right Chemical Injection Pumps for Your Needs

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

What is a Chemical Pump? Understanding Types, Uses, and Benefits for Your Industry

-

2025 Guide to Choosing the Best Chemical Injection Pumps for Your Needs

-

2025 Top 5 Chemical Metering Solutions for Precision and Efficiency

-

Top 10 Chemical Metering Solutions for Accurate and Efficient Measurement