Blog

Understanding the Benefits of Using a Chemical Diaphragm Pump in Industrial Applications

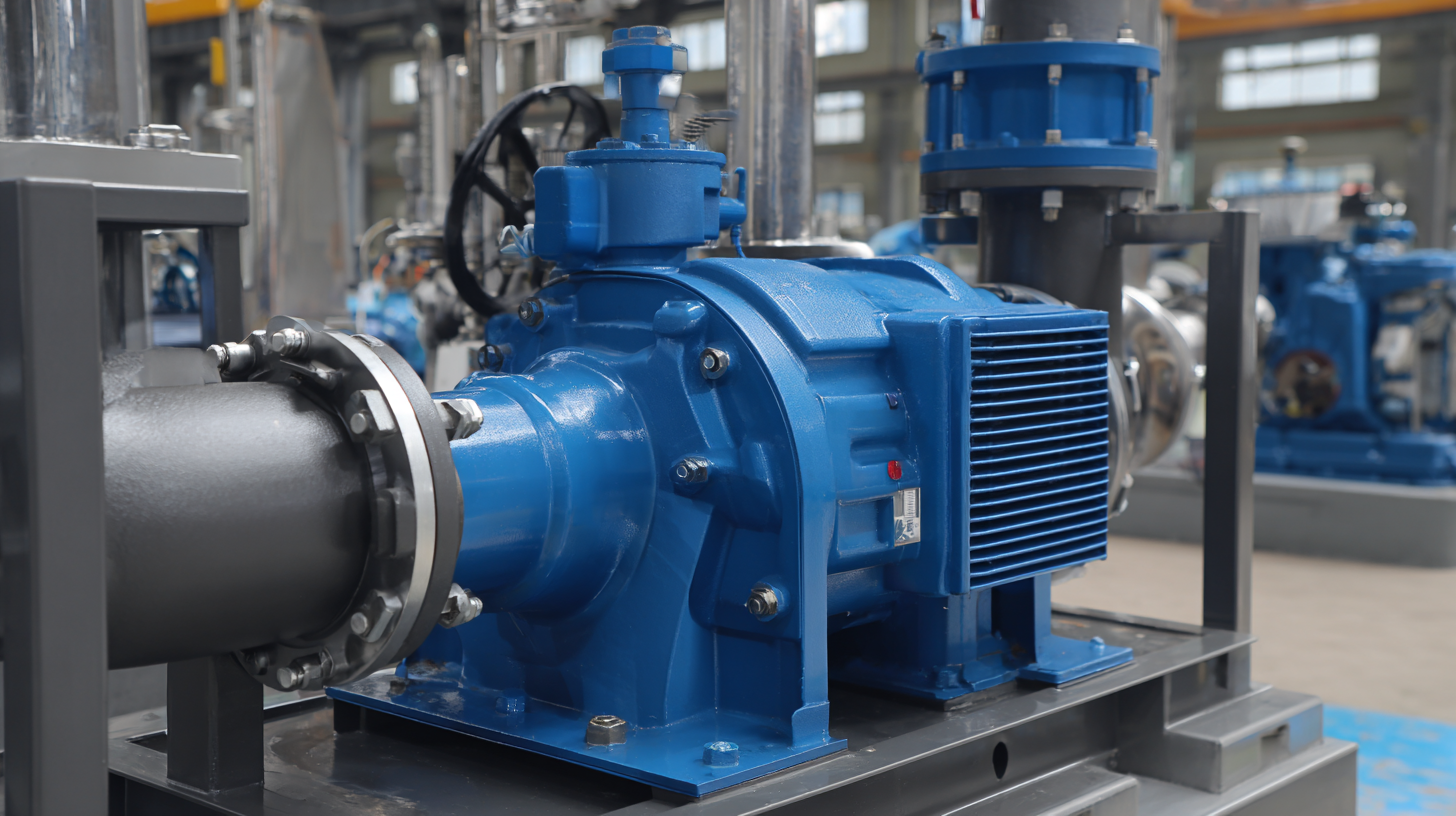

In today's rapidly evolving industrial landscape, the demand for efficient and reliable pumping solutions has never been more critical. Among the various options available, the chemical diaphragm pump stands out for its unique design and numerous advantages in handling a wide range of fluids, especially corrosive or hazardous materials. This pumping technology utilizes a diaphragm to separate the pumped fluid from the drive mechanism, ensuring flawless operation and minimal risk of contamination. As industries increasingly prioritize safety and environmental responsibility, embracing such innovative equipment is essential.

The benefits of using a chemical diaphragm pump extend beyond mere functionality. These pumps are renowned for their exceptional reliability, accuracy, and ability to operate under challenging conditions. They can handle high-viscosity fluids, maintain flow consistency, and provide adjustable flow rates, making them a versatile choice for various applications, from chemical processing to wastewater management. In this article, we will delve into the top 10 advantages of chemical diaphragm pumps, exploring how they can enhance efficiency, reduce operational costs, and contribute to sustainable industrial practices. Understanding these benefits positions businesses to make informed decisions in their pursuit of optimal fluid handling solutions.

Advantages of Chemical Diaphragm Pumps in Harsh Environments

Chemical diaphragm pumps

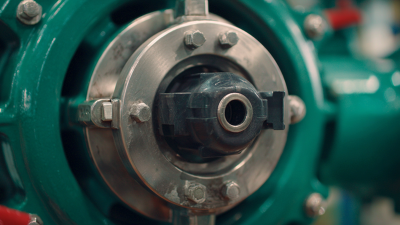

are specifically engineered to handle the rigorous demands of harsh industrial environments. Their design ensures minimal risk of leakage, which is crucial when dealing with corrosive or hazardous liquids. Unlike traditional pumps, diaphragm pumps utilize a flexible membrane that separates the pumping mechanism from the fluid being handled. This unique feature not only offers superior chemical resistance but also enhances the safety profile of the operation, as it prevents any direct contact between the pumped fluids and the mechanical components.

Moreover, the robust construction of chemical diaphragm pumps allows them to function effectively under extreme temperatures and pressures. This reliability makes them ideal for industries such as chemical processing, mining, and wastewater treatment, where conditions can be unpredictable. Additionally, the ability to handle viscous fluids and slurries without significant loss in performance further underscores their versatility.

Operators benefit from reduced maintenance costs and increased uptime, making chemical diaphragm pumps a smart investment for companies aiming to optimize their operations in challenging environments.

Efficiency and Reliability: How Diaphragm Pumps Excel in Industrial Settings

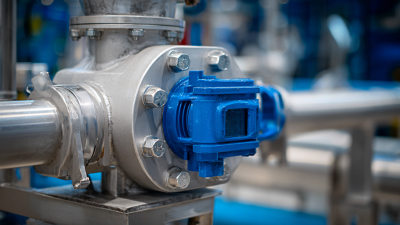

In industrial applications, efficiency and reliability are paramount, and chemical diaphragm pumps stand out as exemplary solutions. These pumps utilize a flexible diaphragm to create a sealed chamber that effectively moves liquids, making them ideal for handling various corrosive substances and slurries. The precision of diaphragm pumps ensures a consistent flow rate, minimizing the risk of spills and leakages that can disrupt operations. Their ability to run dry without damage adds a layer of reliability, ensuring that production processes are not hindered by equipment failure.

Tips for Optimal Use:

When using diaphragm pumps, it’s essential to regularly check for wear and tear on the diaphragms. Maintaining the pump components can significantly extend the lifespan of the equipment. Additionally, carefully selecting materials compatible with the substances being pumped will minimize corrosion and enhance performance.

Another key advantage of diaphragm pumps is their energy efficiency. They require less power to operate compared to traditional pumps, which translates to lower operational costs in the long run. Implementing variable speed drives can further optimize energy consumption, allowing users to adjust the pump speed according to the specific needs of the application. Regular monitoring and adjustments can ensure these pumps perform at peak efficiency.

Cost-Effectiveness: Saving Money with Chemical Diaphragm Pumps

Chemical diaphragm pumps are increasingly recognized for their cost-effectiveness in industrial applications. These pumps offer a reliable solution for transferring various fluids in sectors such as chemical processing and wastewater treatment. One of the most notable advantages of diaphragm pumps is their ability to handle corrosive materials without leaking. This feature significantly reduces the need for expensive containment systems or frequent repairs, ultimately saving money over time.

In addition to their durability, diaphragm pumps require minimal maintenance, which further enhances their cost-efficiency. Operators can achieve optimal performance by implementing efficient operational practices, such as adjusting the pump speed according to the specific needs of the application. This adaptability not only maximizes output but also minimizes energy consumption, leading to lower operational costs. Overall, investing in chemical diaphragm pumps can yield significant long-term savings, making them a smart choice for industries looking to manage their budgets effectively.

Understanding the Benefits of Using a Chemical Diaphragm Pump in Industrial Applications - Cost-Effectiveness: Saving Money with Chemical Diaphragm Pumps

| Dimension | Value |

|---|---|

| Initial Investment Cost | $2,500 |

| Average Maintenance Cost (Annual) | $300 |

| Lifespan (Years) | 10 |

| Estimated Annual Energy Savings | $500 |

| Operational Efficiency Improvement (%) | 20% |

| Total Cost of Ownership (Over Lifespan) | $5,800 |

Versatility of Diaphragm Pumps for Various Industrial Applications

In the realm of industrial applications, diaphragm pumps stand out due to their unmatched versatility and efficiency. With a global market size of approximately USD 6.27 billion in 2023, forecasted to grow significantly in the next decade, diaphragm pumps are increasingly favored for tasks in various sectors, including water treatment, chemical dosing, and wastewater management. Their ability to handle abrasive and viscous fluids makes them ideal for a wide array of industrial needs.

One notable trend is the shift towards electric-operated diaphragm pumps, projected to reach a market size of $941.1 million by 2034, growing at a CAGR of 8.9%. This growth reflects the demand for precision dosing and automation in industrial sectors, essential for maintaining operational efficiency and sustainability. Diaphragm pumps, with their innovative designs, provide a reliable solution for these evolving needs, ensuring effective liquid handling while minimizing environmental impact.

Tips: When selecting a diaphragm pump, consider the specific chemical properties of the fluids being handled to ensure compatibility and longevity of the equipment. Additionally, look for pumps equipped with advanced automation features to enhance precision and reduce labor costs in industrial settings.

Environmental Benefits: Minimizing Chemical Leaks with Diaphragm Technology

Diaphragm pumps are increasingly recognized for their role in minimizing chemical leaks in industrial settings. Utilizing a flexible diaphragm to separate the pump chamber from the motor, these pumps are designed to handle hazardous materials without risking contamination or leakage. This innovative design significantly reduces the likelihood of spills, protecting both the environment and personnel in the vicinity of the pump. By ensuring that chemicals are securely contained during transfer and handling, diaphragm pumps play a crucial part in maintaining workplace safety and regulatory compliance.

Diaphragm pumps are increasingly recognized for their role in minimizing chemical leaks in industrial settings. Utilizing a flexible diaphragm to separate the pump chamber from the motor, these pumps are designed to handle hazardous materials without risking contamination or leakage. This innovative design significantly reduces the likelihood of spills, protecting both the environment and personnel in the vicinity of the pump. By ensuring that chemicals are securely contained during transfer and handling, diaphragm pumps play a crucial part in maintaining workplace safety and regulatory compliance.

Moreover, the environmental benefits of diaphragm pumps extend beyond just preventing leaks. These pumps are often constructed from chemically resistant materials that can withstand harsh substances, ensuring durability and reliability over extended periods. This resilience means fewer replacements and reduced waste, aligning with sustainability goals in many industries. By investing in diaphragm technology, businesses can not only enhance their operational efficiency but also demonstrate a commitment to reducing their ecological footprint, fostering a cleaner and safer environment for all.

Related Posts

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

Understanding the Mechanics of Diaphragm Pumps: The Key to Efficient Fluid Transfer

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

Understanding the Importance of Diaphragm Metering Pumps in Precision Fluid Control

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China