Blog

2025 Top Metering Pump Innovations for Precision Fluid Control

The metering pump industry is undergoing a transformative phase, driven by advancements in technology and increasing demand for precision fluid control across various sectors, including chemical processing, water treatment, and pharmaceuticals. According to the latest report from MarketsandMarkets, the global metering pump market is projected to grow from $4.2 billion in 2021 to $5.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.6%. This growth is fueled by the need for accurate dosing and the rising emphasis on sustainable practices in fluid handling.

Industry expert Dr. Emily Chen, a prominent figure in fluid dynamics and metering pump technology, emphasizes the significance of innovation in this sector: "The future of metering pumps lies in their ability to adapt to a variety of applications with unmatched precision." As we explore the top metering pump innovations anticipated in 2025, it becomes clear that advancements such as smart technology integration, improved materials, and enhanced design will play crucial roles in meeting industry demands.

This article will delve into the emerging trends and technologies shaping the future of metering pumps, showcasing how these innovations not only enhance performance but also contribute to greater environmental sustainability and operational efficiency. Companies that harness these advancements will not only improve their competitive edge but also redefine standards in fluid management practices.

Emerging Technologies in Metering Pump Design for Enhanced Accuracy

The advancements in metering pump design are paving the way for enhanced precision in fluid control applications. With the integration of emerging technologies, these innovations are focused on improving accuracy and efficiency. The incorporation of Internet of Things (IoT) solutions enables real-time monitoring and data analysis, facilitating better decision-making and operational adaptability in various industrial settings. This aspect is particularly crucial as industries increasingly seek to reduce downtime and optimize resource management.

Moreover, the growing demand in the dosing pumps market, projected to reach over USD 7.8 billion by 2024, showcases the significance of these innovations. New product releases, such as those featuring advanced drive technologies, highlight the commitment to meeting the evolving needs of the market. These developments not only enhance the functionality of dosing pumps but also contribute to longer lifespans and reduced maintenance costs, ultimately benefiting end-users in sectors ranging from municipal water treatment to chemical processing.

2025 Top Metering Pump Innovations for Precision Fluid Control

| Innovation | Feature | Accuracy Improvement (%) | Application Area | Estimated Release Date |

|---|---|---|---|---|

| Smart Sensor Integration | Real-time feedback for flow adjustments | 25% | Chemical Processing | Q3 2025 |

| AI-Driven Optimization | Machine learning algorithms for predictive maintenance | 30% | Water Treatment | Q2 2025 |

| Enhanced Sealing Technology | Reduce leakage and improve lifespan | 20% | Oil and Gas | Q1 2025 |

| Remote Monitoring Solutions | IoT connectivity for remote operation | 35% | Pharmaceuticals | Q4 2025 |

| Variable Speed Drives | Energy-efficient flow control | 15% | Food Processing | Q3 2025 |

Integration of Smart Sensors for Real-Time Fluid Monitoring

The integration of smart sensors in metering pumps represents a significant leap forward in precision fluid control. These sensors, equipped with advanced capabilities, enable real-time monitoring of fluid dynamics, ensuring optimal performance and reliability. By continuously analyzing the flow rates, pressures, and viscosity of the fluids being handled, smart sensors can provide immediate feedback to operators, allowing for quick adjustments and preventing costly errors in industrial applications.

Moreover, the data collected by these sensors can be integrated into a centralized control system, facilitating predictive maintenance and reducing downtime. The insights gained from real-time monitoring empower users to make data-driven decisions, enhancing both operational efficiency and safety.

As industries increasingly demand high accuracy and responsiveness in fluid management, the deployment of smart sensors in metering pumps is not just an innovation; it is a transformative approach that aligns with the evolving landscape of industrial automation and control technologies.

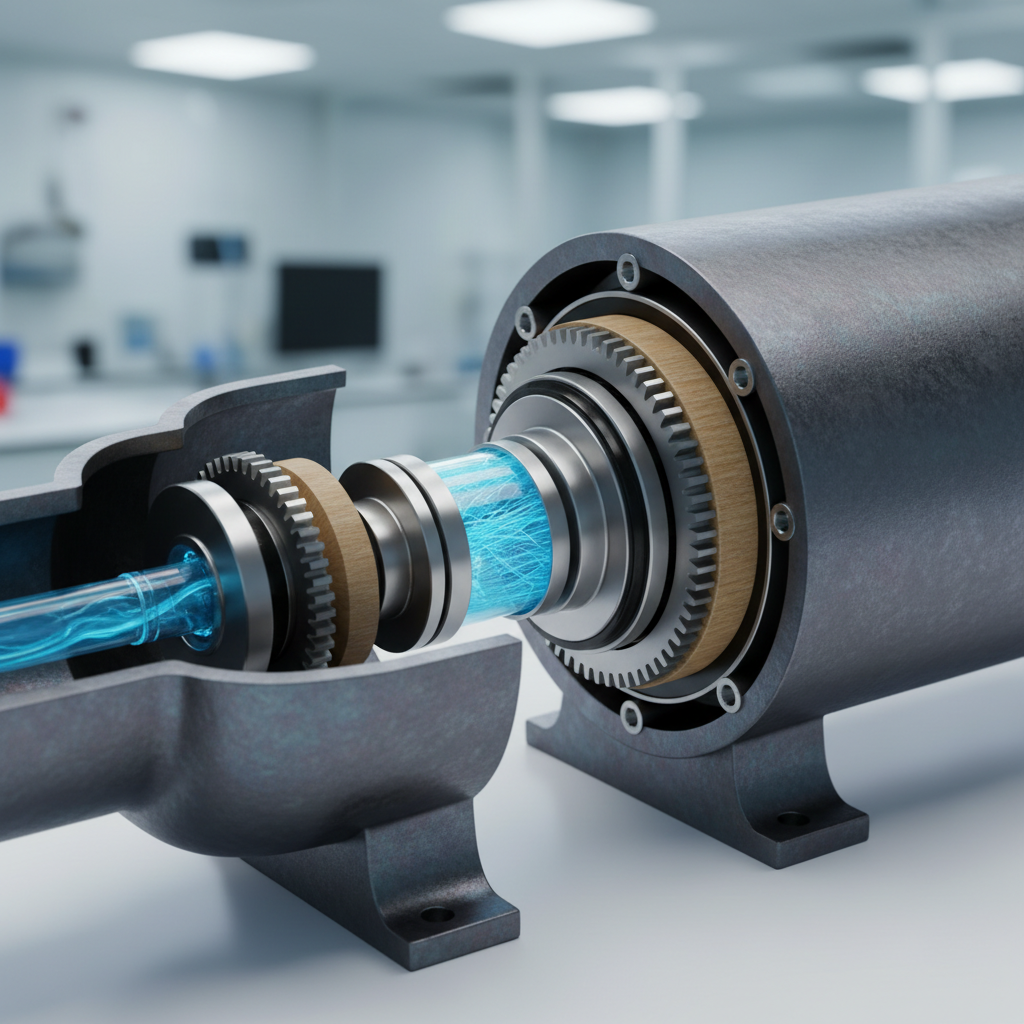

Advancements in Materials for Improved Pump Longevity and Reliability

The advancements in materials for metering pumps are crucial in enhancing both longevity and reliability, which are essential for precision fluid control. In 2025, innovations such as advanced polymers and ceramic composites are being explored to withstand harsh chemical environments and reduce wear. These materials not only improve resistance to corrosion and abrasion but also contribute to overall pump efficiency, leading to fewer breakdowns and longer maintenance intervals.

Moreover, the incorporation of smart materials like shape memory alloys is revolutionizing how pumps respond to varying fluid types and conditions. These materials can adapt their properties based on external stimuli, ensuring optimal performance under diverse operating circumstances. As manufacturers adopt these cutting-edge materials, metering pumps are expected to achieve unprecedented levels of accuracy and durability, setting new standards in fluid management applications across various industries.

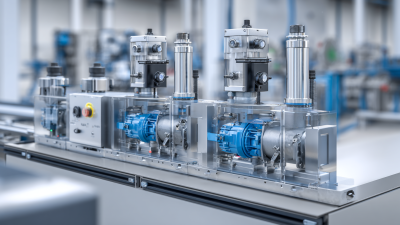

Automation and IoT in Metering Pumps: The Future of Fluid Management

The future of fluid management is increasingly being shaped by

automation and the

Internet of Things (IoT), especially in the realm of

metering pumps. As these technologies evolve, they bring enhanced precision and

efficiency to fluid control processes.

Automated metering pumps equipped with IoT capabilities can communicate data in real-time, allowing operators to monitor

and adjust fluid delivery remotely. This level of connectivity not only streamlines operations but also reduces the

risk of human error, leading to more reliable and consistent performance.

Moreover, the integration of IoT in metering pumps facilitates

predictive maintenance, a pivotal advancement for

industries reliant on fluid management. By analyzing data collected from various sensors, operators can anticipate

equipment failures and schedule maintenance before issues arise. This proactive approach ensures minimal downtime and

extends the lifespan of pump systems, ultimately contributing to

significant cost savings. As we approach

2025, these innovations will not only optimize fluid control

but also position metering pumps as vital components in smarter, more efficient industrial ecosystems.

Energy Efficiency Innovations in Metering Pumps for Sustainable Operations

The metering pump industry is undergoing a significant transformation as innovation in energy efficiency takes center stage. With a growing emphasis on sustainable operations, manufacturers are developing pumps that not only deliver precise fluid control but also minimize energy consumption. Advanced motor technologies and variable-speed controllers enable these pumps to adjust their output to match the specific requirements of diverse applications, ensuring optimal performance while conserving energy.

Furthermore, the integration of smart technologies into metering pumps is enhancing their energy efficiency. IoT-enabled systems allow for real-time monitoring and data analysis, which leads to more informed decision-making regarding pump operation. Predictive maintenance capabilities can also reduce downtime and extend equipment life, further supporting sustainable practices. This shift towards energy-efficient metering pumps reflects a broader trend within the industry to prioritize environmental responsibility while maintaining reliability and precision in fluid management.

Related Posts

-

Understanding the Role of Industrial Metering Pumps in Modern Manufacturing Processes

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency

-

Understanding the Importance of Metering Pumps in Modern Industrial Applications