Blog

2025 Top Chemical Metering Pump Innovations and Best Practices

The landscape of chemical metering pump technology is evolving rapidly, driven by innovations that enhance performance, reliability, and efficiency. As industries increasingly rely on precise fluid handling for their operations, the significance of advanced chemical metering pumps cannot be overstated. These devices are essential for ensuring accurate dosing of chemicals in various applications, ranging from water treatment to pharmaceutical manufacturing. The year 2025 promises to showcase groundbreaking advancements and best practices in this field, presenting opportunities for businesses to optimize their processes.

This article explores the top innovations expected to shape the future of chemical metering pumps, from improved materials to enhanced control systems. It will also highlight best practices that organizations can adopt to maximize the potential of these technologies. By staying informed about the latest trends and developments, companies can make informed decisions that improve operational efficiency, reduce costs, and maintain compliance with industry standards. As we delve into the specifics of these advancements, readers will gain valuable insights into the transformative role that chemical metering pumps will play in the coming years.

Emerging Trends in Chemical Metering Pump Technologies for 2025

In 2025, the chemical metering pump industry is poised for significant advancements driven by emerging technologies and evolving operational needs. Recent industry reports indicate a growing demand for precision and efficiency, with the global metering pump market expected to reach $3.5 billion by 2025, showcasing a CAGR of 4.2% from 2021. This demand is largely propelled by sectors such as water treatment, petrochemicals, and pharmaceuticals, where accurate chemical dosing is critical to process optimization and compliance with safety regulations.

Notably, digital technologies are transforming chemical metering pump operations. The integration of IoT and smart sensors enables real-time monitoring and predictive maintenance, significantly mitigating downtime and enhancing operational efficiencies. According to a report from a leading industrial analysis firm, nearly 60% of organizations are expected to adopt smart metering solutions by 2025, facilitating better responsiveness to varying operational demands. Additionally, the push for sustainability is influencing the design of metering pumps, with an increasing number of manufacturers focusing on reducing energy consumption and minimizing waste, thus aligning with global sustainability goals. With these trends, the future of chemical metering pumps is clearly heading towards a more intelligent and eco-friendly paradigm.

Key Innovations in Pump Design Enhancements and Efficiency Gains

Innovations in chemical metering pump design are pivoting towards enhanced efficiency and operational effectiveness. One significant advancement is the integration of smart technology, which enables real-time monitoring and control. This innovation allows operators to adjust parameters remotely, improving the responsiveness of chemical dosing and reducing the risk of human error. Furthermore, the incorporation of advanced materials is enhancing the durability and chemical compatibility of pumps, which is crucial for handling a wide range of fluids while minimizing maintenance needs.

Another key enhancement is the development of more precise metering capabilities, thanks to innovative flow measurement technologies. These advancements ensure that chemical additives are delivered with greater accuracy, reducing waste and improving overall process efficiency. Additionally, energy-efficient motor designs are becoming increasingly common, resulting in lower operational costs and a reduced carbon footprint. As companies seek to streamline their processes and enhance sustainability, these innovations in metering pump design are proving essential for meeting modern industrial demands.

Best Practices for Selecting and Maintaining Chemical Metering Pumps

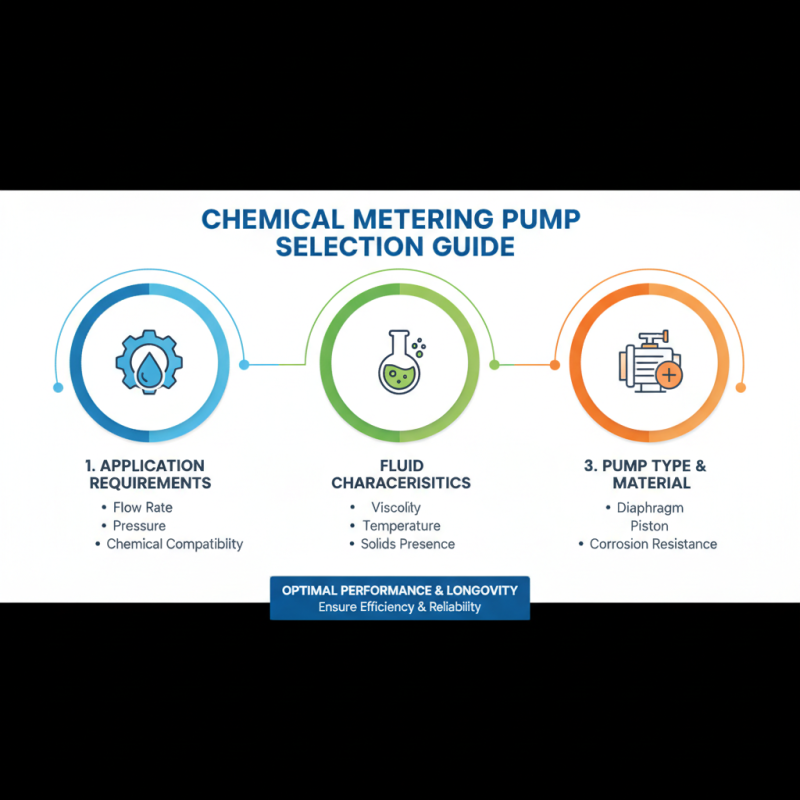

When selecting chemical metering pumps, it's crucial to consider several factors to ensure optimal performance and longevity. First, the specific application requirements should guide the choice of pump type. Different processes may require varying flow rates, pressures, and chemical compatibilities. Conducting a thorough analysis of the fluid characteristics, including viscosity, temperature, and the presence of solids, will help in selecting a pump that can effectively handle the operational demands without compromising efficiency.

Maintenance practices play a vital role in the longevity and reliability of chemical metering pumps. Regular inspection of components, including seals and fittings, is essential to prevent leaks and ensure accurate dosing. Implementing a routine maintenance schedule to clean and calibrate pumps will help identify potential issues before they escalate, reducing downtime and preventing costly repairs. Additionally, training personnel on proper pump operation and maintenance procedures can lead to better performance and a longer service life, minimizing disruptions in chemical delivery processes.

Integrating IoT and Automation in Chemical Metering Pump Systems

The integration of IoT and automation in chemical metering pump systems is revolutionizing the way these devices are utilized across various industries. By embedding sensors and connectivity features into metering pumps, operators can monitor and control chemical dosing processes in real-time. This shift not only enhances accuracy and efficiency but also minimizes the risks associated with manual interventions. With the ability to gather and analyze operational data, companies can optimize their chemical usage, reduce waste, and ensure compliance with safety standards.

Moreover, automation allows for seamless integration with existing manufacturing systems, facilitating better communication between different machinery and software platforms. Through smart algorithms and predictive analytics, chemical metering pumps can adjust flow rates dynamically based on real-time feedback, ensuring consistent performance under varying operational conditions. This level of automation not only enhances operational efficiency but also empowers personnel to focus on strategic decision-making rather than routine monitoring tasks.

Overall, the adoption of IoT and automation in chemical metering pump systems signifies a crucial step towards more sustainable and efficient industrial processes.

Sustainability Practices in Chemical Metering Pump Operations for 2025

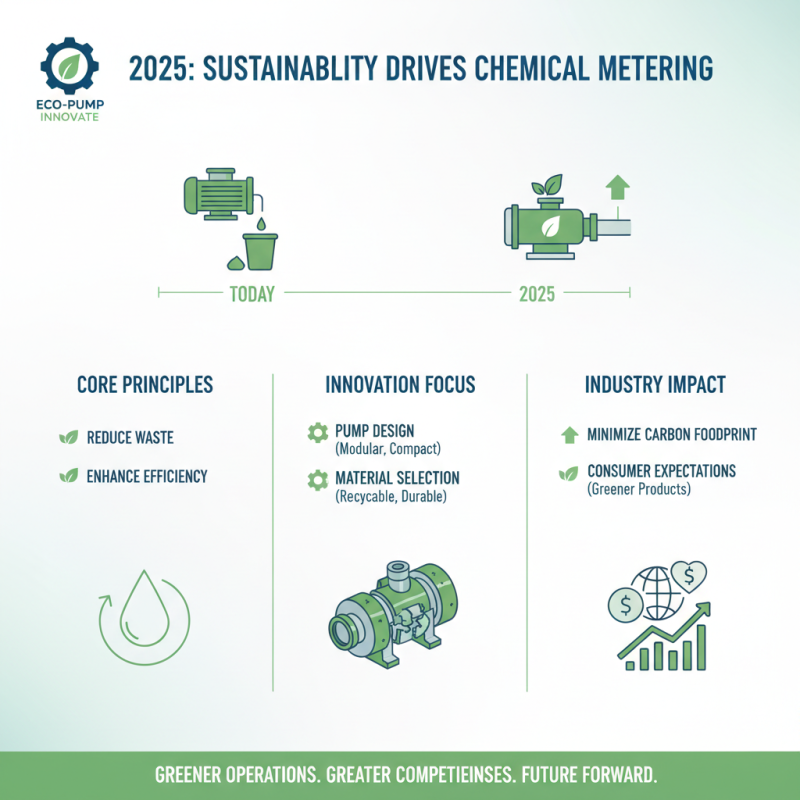

In 2025, sustainability will be at the forefront of chemical metering pump operations, pushing industries to adopt environmentally responsible practices. The emphasis on reducing waste and enhancing efficiency in fluid delivery systems will drive innovations in pump design and material selection. Companies will increasingly focus on using recyclable materials and energy-efficient technologies to minimize their carbon footprint. This shift not only benefits the environment but also aligns with consumer expectations for greener products, fostering brand loyalty and market competitiveness.

Moreover, best practices in sustainability will include regular maintenance schedules to extend equipment life and minimize resource consumption. Implementing advanced monitoring systems will allow for real-time data analysis, enabling operators to optimize performance and identify leaks or inefficiencies promptly. Additionally, training personnel on sustainable practices will create a more environmentally conscious workforce, ensuring that every level of operation prioritizes sustainability. By integrating these practices, businesses can position themselves as leaders in the industry while contributing to a more sustainable future.

Related Posts

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency

-

Understanding the Importance of Chemical Pumps in Modern Industrial Processes

-

Understanding the Role of Chemical Feed Pumps in Modern Industrial Applications

-

Understanding the Benefits of Chemical Metering Pumps in Modern Water Treatment Systems